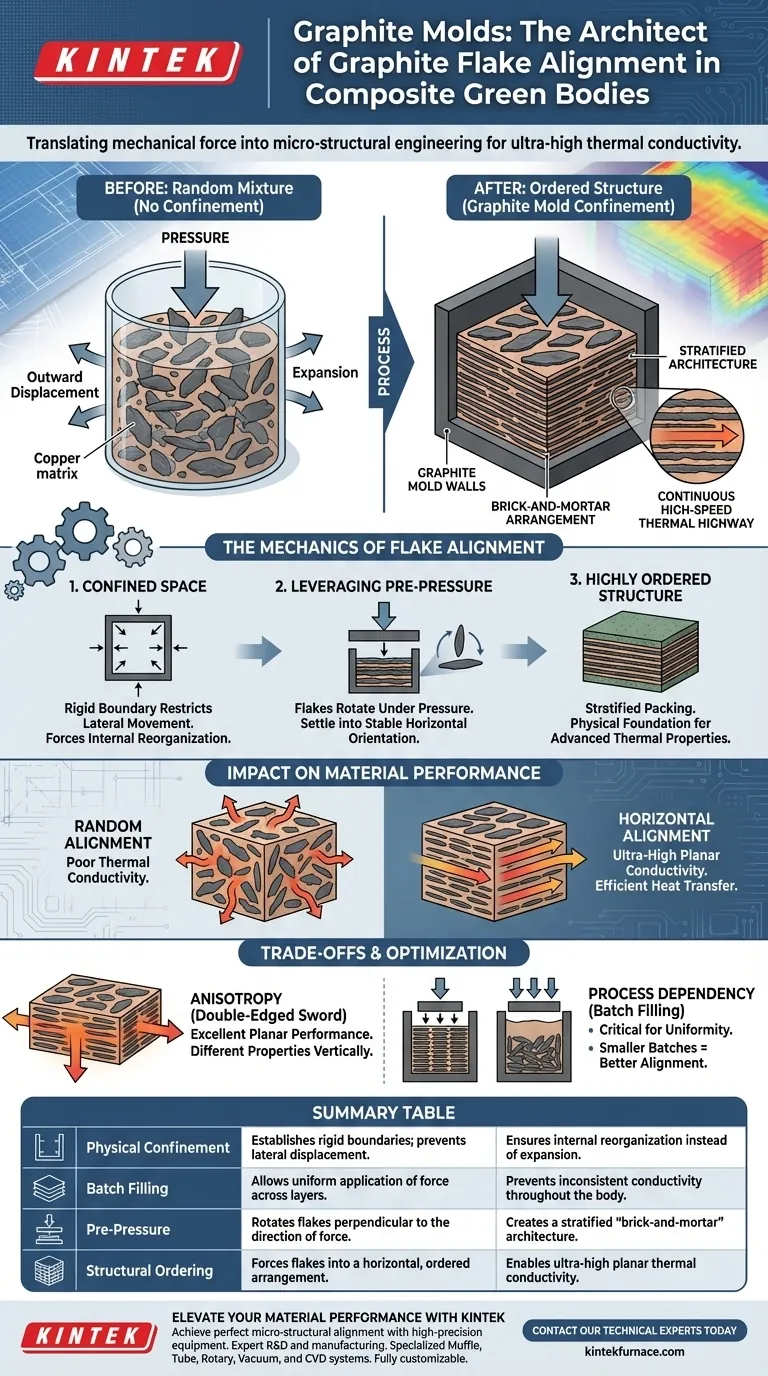

Graphite molds serve as the critical physical constraint mechanism that forces random graphite flakes into a strictly ordered arrangement. During the preparation of green bodies, the mold confines the composite mixture, allowing applied pressure to physically rotate and flatten the flakes so they lie perpendicular to the direction of force.

The mold provides the necessary confined geometry to transform a random mixture into an engineered structure. By combining physical confinement with batch filling and pre-pressure, the mold dictates the horizontal orientation of large graphite flakes, which is the absolute prerequisite for achieving ultra-high thermal conductivity.

The Mechanics of Flake Alignment

The Function of Confined Space

The primary role of the graphite mold is to establish a rigid, defined boundary. Without this confinement, the composite material would simply displace outwards under pressure rather than reorganizing internally.

The mold walls effectively restrict lateral movement. This forces the internal components of the mixture to reorganize within the existing volume, directing energy toward alignment rather than expansion.

Leveraging Pre-Pressure for Orientation

When the mixture is added to the mold in batches, pre-pressure is applied. Because the space is confined, the large graphite flakes cannot move randomly.

To accommodate the reduction in volume, the flakes are forced to rotate. They settle into the most stable physical position, which is a horizontal orientation perpendicular to the pressing direction.

Creating a Highly Ordered Structure

The result of this process is not a random packing of particles, but a stratified architecture. The mold ensures that the flakes stack neatly on top of one another.

This creates a "brick-and-mortar" style arrangement. This ordered alignment is not merely aesthetic; it is the physical foundation required for the material's advanced thermal properties.

The Impact on Material Performance

Defining the Conductivity Path

Heat travels most efficiently along the plane of graphite flakes, not through them. The alignment dictated by the mold aligns these conductive planes.

By forcing the flakes into a horizontal direction, the mold creates a continuous high-speed highway for thermal energy.

Unlocking Ultra-High Planar Conductivity

The specific alignment achieved in the mold directly correlates to the final green body's performance.

The reference notes that this horizontal order is the "physical prerequisite" for success. Without the mold to enforce this directionality, achieving ultra-high thermal conductivity in the planar direction is physically impossible.

Understanding the Trade-offs

Anisotropy is a Double-Edged Sword

The mold creates a material that is highly anisotropic. While this results in excellent performance in the planar (horizontal) direction, it implies different properties in the vertical direction.

You must design your application understanding that heat transfer will be significantly more efficient across the surface than through the thickness of the material.

Process Dependency

The alignment quality is heavily dependent on the "batch filling" technique mentioned in the reference.

If the mold is filled all at once rather than in batches, the alignment effect of the pre-pressure may diminish deep within the mold. This could lead to inconsistent conductivity throughout the green body.

Maximizing Alignment Efficiency

To ensure you are utilizing the graphite mold effectively for composite preparation, consider the following:

- If your primary focus is maximum thermal conductivity: Prioritize smaller batch sizes during filling to ensure every layer of flakes is subjected to sufficient pre-pressure for perfect horizontal alignment.

- If your primary focus is geometric precision: Rely on the rigid confinement of the graphite mold to prevent lateral displacement, ensuring the final green body maintains exact dimensions while the internal structure reorients.

The graphite mold is the tool that translates mechanical force into micro-structural engineering, turning raw pressure into precise material performance.

Summary Table:

| Mechanism | Role in Alignment | Impact on Material |

|---|---|---|

| Physical Confinement | Establishes rigid boundaries; prevents lateral displacement. | Ensures internal reorganization instead of expansion. |

| Batch Filling | Allows uniform application of force across layers. | Prevents inconsistent conductivity throughout the body. |

| Pre-Pressure | Rotates flakes perpendicular to the direction of force. | Creates a stratified "brick-and-mortar" architecture. |

| Structural Ordering | Forces flakes into a horizontal, ordered arrangement. | Enables ultra-high planar thermal conductivity. |

Elevate Your Material Performance with KINTEK

Achieving the perfect micro-structural alignment in your graphite/copper composites requires high-precision equipment designed for rigorous lab and industrial standards. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique materials engineering needs.

Ready to transform raw pressure into precise material performance? Contact our technical experts today to find the ideal thermal solution for your lab.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- What advantages does a vacuum drying oven offer for BiFeO3 electrode sheets? Optimize Your Battery Research

- What is a vacuum chamber good for? Mastering Material Processing with Environmental Control

- Why is a corundum crucible required for the sintering of manganese ore at 1200 °C? Ensure High-Purity Results

- How do graphite sleeves and ceramic crucibles function in induction furnaces? Key Roles in Material Synthesis

- Why use alumina crucibles for NaNbO3:Pr3+ annealing? Ensure High Purity and Thermal Stability

- What are the thermal properties of alumina tubes? Discover Their High-Temp Durability and Stability

- What is the function of high-purity graphite crucibles in Al-Cu-Mn master alloy prep? Ensure Chemical Purity

- How do alumina ceramic furnace tubes compare to other materials like quartz or silicon carbide? Choose the Best for Your High-Temp Needs