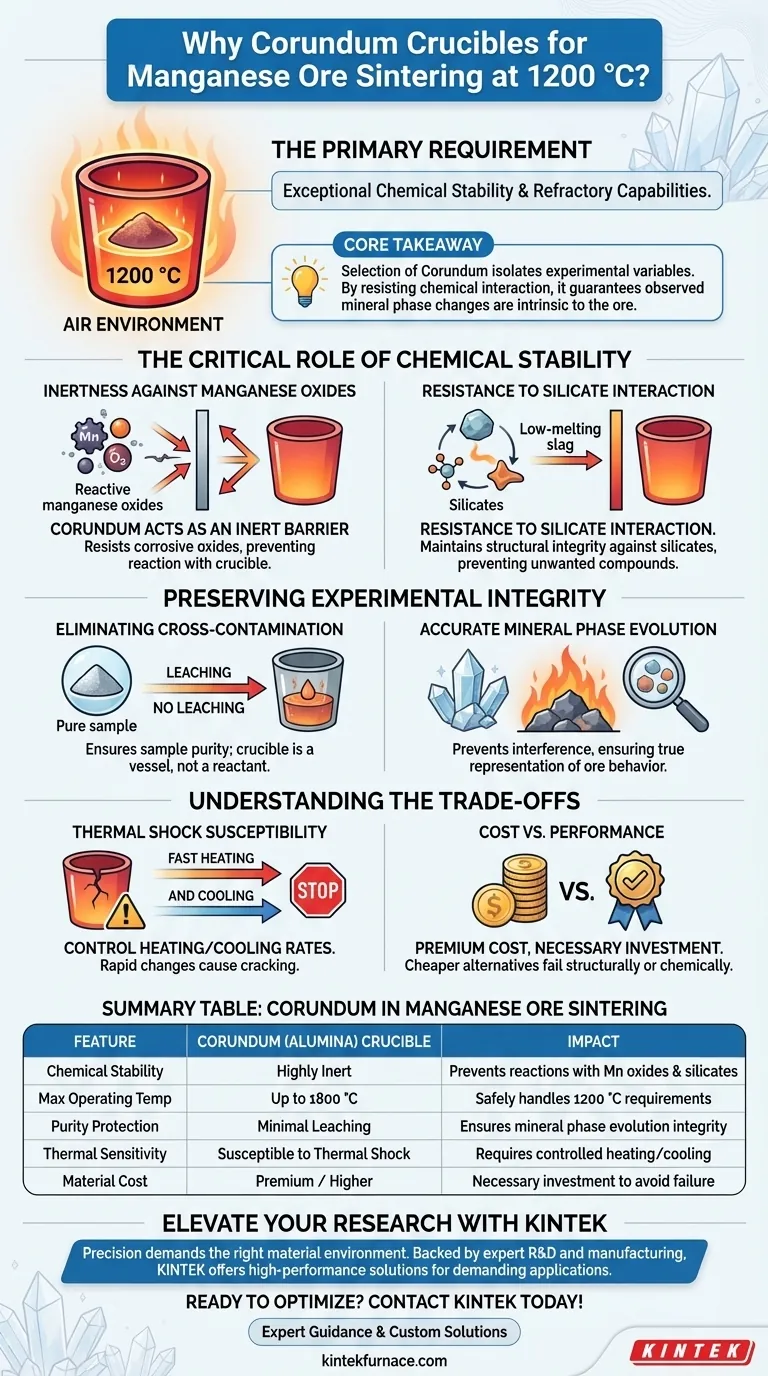

The primary requirement for using a corundum crucible in this specific application stems from its exceptional chemical stability and refractory capabilities in high-temperature air environments. When sintering manganese ore at 1200 °C, corundum remains chemically inert, ensuring it does not react with the manganese oxides or silicate components present in the sample.

Core Takeaway The selection of corundum is critical for isolating your experimental variables. By resisting chemical interaction with manganese ore at high heat, corundum guarantees that any observed mineral phase changes are intrinsic to the ore itself, not a byproduct of container contamination.

The Critical Role of Chemical Stability

Inertness Against Manganese Oxides

At elevated temperatures, manganese oxides become highly reactive and can aggressively attack many standard crucible materials.

Corundum acts as an inert barrier. It resists the corrosive nature of these oxides in an air environment, preventing the crucible walls from dissolving into the melt or reacting with the sample.

Resistance to Silicate Interaction

Manganese ore frequently contains silicate components, which can form low-melting-point slags when in contact with incompatible crucible materials.

Corundum maintains its structural integrity against these silicates. This prevents the formation of unwanted compounds that would otherwise alter the chemical composition of your sample.

Preserving Experimental Integrity

Eliminating Cross-Contamination

The validity of a sintering experiment depends entirely on the purity of the final product.

If the crucible material leaches into the ore, the resulting chemical data is compromised. Corundum ensures the sample remains pure, acting solely as a vessel rather than a reactant.

Accurate Mineral Phase Evolution

Researchers use sintering to observe how mineral phases evolve and change under heat.

Because corundum prevents interference from the container material, you can be confident that the phase evolution observed is a true representation of the ore's behavior at 1200 °C, rather than an artifact of foreign material interaction.

Understanding the Trade-offs

Thermal Shock Susceptibility

While corundum is chemically superior for this application, it is mechanically sensitive to rapid temperature changes.

You must control heating and cooling rates carefully. Rapid quenching or sudden heating can cause corundum crucibles to crack or shatter due to thermal shock, potentially destroying the sample despite the chemical compatibility.

Cost vs. Performance

Corundum is generally more expensive than lower-grade ceramics like porcelain or standard alumina-silicates.

However, for sintering manganese at 1200 °C, this cost is a necessary investment. Cheaper alternatives would likely fail structurally or chemically, rendering the experiment void.

Making the Right Choice for Your Goal

To ensure your high-temperature experiments yield valid data, align your equipment choice with your specific objectives:

- If your primary focus is Data Accuracy: Stick strictly to corundum to prevent manganese oxides and silicates from reacting with the vessel walls.

- If your primary focus is Equipment Longevity: Implement slow ramp rates for both heating and cooling to mitigate corundum's vulnerability to thermal shock.

By choosing corundum, you prioritize the chemical fidelity of your research over the lower cost of inferior materials.

Summary Table:

| Feature | Corundum (Alumina) Crucible | Manganese Ore Sintering Impact |

|---|---|---|

| Chemical Stability | Highly Inert | Prevents reactions with manganese oxides and silicates |

| Max Operating Temp | Up to 1800 °C | Safely handles 1200 °C sintering requirements |

| Purity Protection | Minimal Leaching | Ensures mineral phase evolution is not compromised |

| Thermal Sensitivity | Susceptible to Thermal Shock | Requires controlled heating/cooling to prevent cracking |

| Material Cost | Premium / Higher | Necessary investment to avoid experimental failure |

Elevate Your High-Temperature Research with KINTEK

Precision in sintering requires more than just heat; it demands the right material environment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with high-performance laboratory crucibles tailored for your most demanding applications. Whether you are sintering manganese ore or developing advanced ceramics, our customizable high-temperature solutions ensure the integrity of your data and the efficiency of your lab.

Ready to optimize your thermal processes? Contact KINTEK today for expert guidance and custom solutions!

Visual Guide

References

- Ruslan Sаfarov, L. De Los Santos Valladares. Phase Transitions and Structural Evolution of Manganese Ores During High-Temperature Treatment. DOI: 10.3390/met15010089

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the maximum vacuum capacity of the water circulating vacuum pump? Uncover Its Ideal Lab Applications

- What are the primary functions of a quartz tube reactor? Enhance Hydrogen Production and Induction Efficiency

- Why is an alumina crucible necessary when synthesizing U0.92Mn3Si2C inside a quartz tube? Ensure Vessel Integrity

- What functions does the hot pressing mold perform? Key Roles in Al3Ti/Al Composite Powder Metallurgy

- What chemical resistance properties should be verified for alumina ceramic furnace tubes? Ensure High-Temperature Durability

- What is the function of precision magnetic heating stirring equipment in BCZT ceramic preparation? Achieve Homogeneity

- Why is precise temperature sensor placement critical in high-temp viscometers? Expert Insights for Accurate Melt Data

- What function does a PTFE liner serve in NiWO4 synthesis? Ensure Purity & Prevent Corrosion in Hydrothermal Reactors