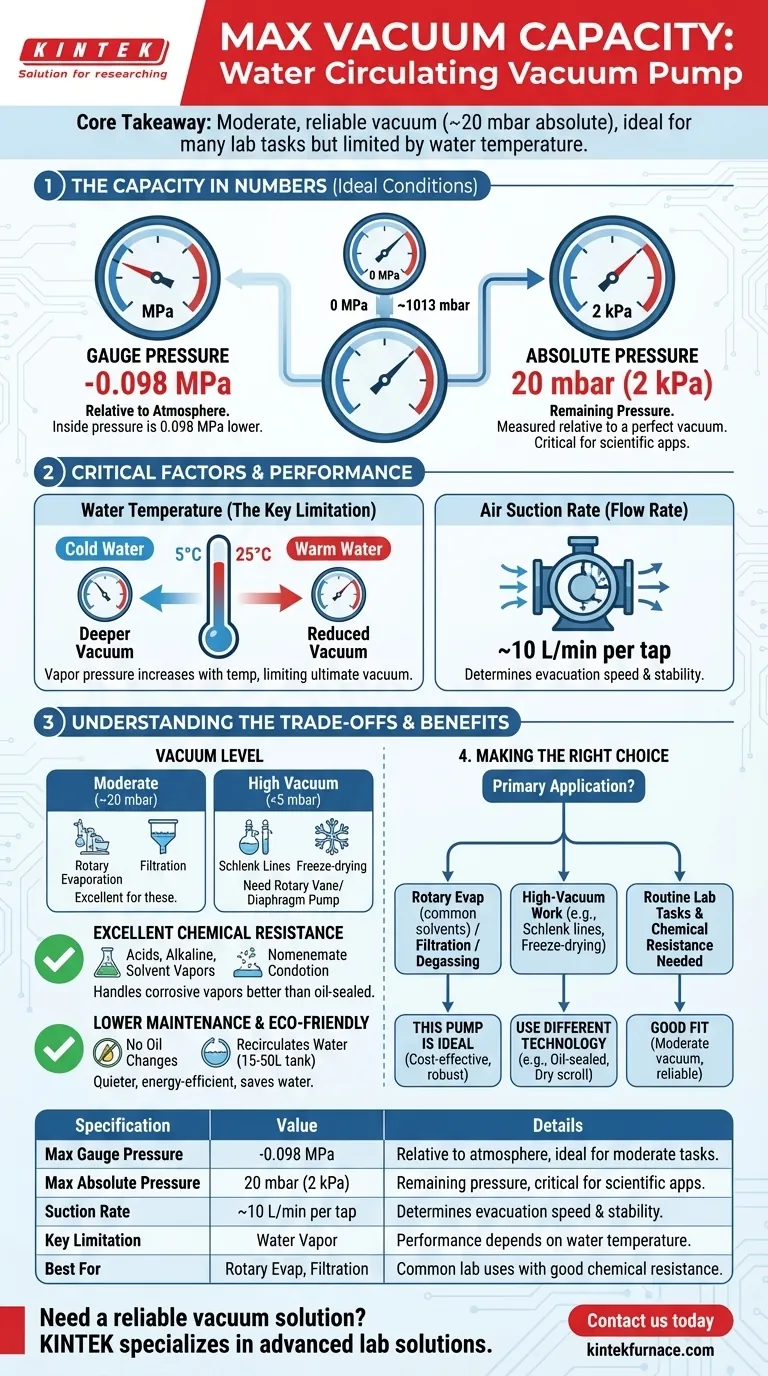

In short, the maximum vacuum capacity for a typical water circulating vacuum pump is -0.098 MPa in gauge pressure. This means it removes 0.098 MPa of pressure relative to the atmosphere, resulting in a final absolute pressure of approximately 20 mbar (2 kPa) under ideal conditions.

The core takeaway is that a water circulating vacuum pump provides a moderate, reliable vacuum suitable for many common lab applications. However, its ultimate performance is not a fixed number; it is fundamentally limited by the vapor pressure of the circulating water, making water temperature a critical performance factor.

How to Interpret Vacuum Specifications

To properly evaluate if this pump meets your needs, you must understand what these numbers mean in practice. The specifications are not just numbers; they describe the pump's physical limits and behavior.

Absolute vs. Gauge Pressure

A common point of confusion is the difference between gauge and absolute pressure.

Gauge pressure measures the pressure difference relative to the local atmosphere. A value of -0.098 MPa indicates the pressure inside the system is 0.098 MPa lower than the pressure outside.

Absolute pressure is the remaining pressure in the system, measured relative to a perfect vacuum. For this pump, the best-case absolute pressure is 20 mbar (or 2 kPa). This is the number that matters most for scientific applications like distillation.

The Critical Role of Water Temperature

The ultimate vacuum a water pump can achieve is physically limited by the vapor pressure of the water used as the working fluid. The pump cannot create a vacuum deeper than the pressure the water itself is exerting as it evaporates.

Colder water has a lower vapor pressure, which allows the pump to achieve a deeper vacuum. As the pump operates, the water will heat up, its vapor pressure will rise, and the achievable vacuum level will decrease.

Air Suction Rate (Flow Rate)

The maximum vacuum is a static measurement achieved under a no-load condition. In practice, the suction rate—often cited around 10 L/min per tap—is just as important.

This value determines how quickly the pump can evacuate a vessel or overcome small leaks in your setup. A higher flow rate leads to faster results and a more stable vacuum during a process.

Understanding the Trade-offs

No single pump is perfect for every task. A water circulating vacuum pump offers a specific set of advantages and limitations that make it ideal for some applications and unsuitable for others.

Vacuum Level vs. Other Pump Types

The ~20 mbar vacuum of a water pump is considered moderate. It is perfectly adequate for evaporating common solvents like ethanol or for vacuum filtration.

However, it is not a "high vacuum" pump. Applications requiring pressures below 5 mbar, such as drying sensitive compounds to a fine powder or distilling high-boiling-point substances, demand a more powerful pump like a rotary vane pump (<0.01 mbar) or a multi-stage diaphragm pump (~2 mbar).

Excellent Chemical Resistance

A significant advantage is its inherent resistance to corrosive vapors. Since the working fluid is water and internal components are often polymer or stainless steel, these pumps handle acidic, alkaline, and solvent vapors far better than oil-sealed pumps. This drastically reduces maintenance and contamination risk.

Lower Maintenance and Environmental Impact

Compared to an oil-sealed pump, a water circulator is simpler, with no oil to monitor or change. Compared to a water aspirator running on a tap, it saves a tremendous amount of water by recirculating it from a built-in tank (typically 15-50 liters). They also tend to be quieter and more energy-efficient.

Making the Right Choice for Your Goal

Select your vacuum source based on the demands of your primary application.

- If your primary focus is rotary evaporation of common solvents (e.g., ethanol, DCM, water): This pump is an excellent, cost-effective, and robust choice.

- If your primary focus is vacuum filtration, degassing, or aspiration: The moderate vacuum and good flow rate are ideal for these routine lab tasks.

- If your primary focus is high-vacuum work (e.g., Schlenk lines, freeze-drying, distilling high-boiling compounds): You must use a different technology, such as an oil-sealed rotary vane or a dry scroll pump.

Ultimately, a water circulating vacuum pump is a versatile workhorse for the modern chemistry lab, valued for its simplicity and reliability, not its extreme performance.

Summary Table:

| Specification | Value | Details |

|---|---|---|

| Max Gauge Pressure | -0.098 MPa | Pressure relative to atmosphere, ideal for moderate vacuum tasks. |

| Max Absolute Pressure | 20 mbar (2 kPa) | Remaining pressure in system, critical for scientific applications. |

| Suction Rate | ~10 L/min per tap | Determines evacuation speed and stability during operations. |

| Key Limitation | Water vapor pressure | Performance depends on water temperature; colder water enables deeper vacuum. |

| Best For | Rotary evaporation, filtration, degassing | Suitable for common lab uses with good chemical resistance and low maintenance. |

Need a reliable vacuum solution for your lab? KINTEK specializes in high-temperature furnaces and vacuum systems, leveraging our strong R&D and in-house manufacturing to deliver advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With deep customization capabilities, we precisely meet unique experimental requirements for diverse laboratories. Contact us today to discuss how our expertise can enhance your efficiency and results!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a precision programmed cooling system influence the structural integrity of Al2O3-TiC composite materials?

- Why is the use of high-alumina crucibles essential for NCM811? Ensure Purity in High-Nickel Cathode Synthesis

- What is the primary function of a high-energy planetary ball mill? Unlock Nanoscale Ceramic Pretreatment

- Why are hard tungsten carbide alloy balls used for SSBSN milling? Ensure Purity with Wear-Resistant Media

- Why is a stainless steel crucible selected for melting AM60 magnesium alloy? Ensure Alloy Purity and Safety

- What materials are used in the construction of a water circulating vacuum pump? Key Components for Durability

- Why is a heating device with magnetic stirring required for Y2O3-MgO precursors? Ensure Perfect Particle Coating

- What function do graphite chill plates or chill rings perform? Master Single-Crystal Blade Directional Solidification