To prevent collapse under vacuum, a furnace retort relies on specific structural engineering principles to withstand the immense crushing force of external atmospheric pressure. Rather than being "sucked in," the retort is being compressed from all sides. The design counteracts this force through reinforcement, typically using corrugations or external support rings to add stiffness and prevent the walls from buckling.

A vacuum does not pull; the atmosphere pushes. The engineering challenge for a vacuum retort is not to contain nothing, but to resist the crushing weight of the air outside it, a force of nearly 15 pounds on every square inch of its surface, especially when the retort's material is weakened by extreme heat.

The Physics of Vacuum Collapse

It's Not Suction, It's Compression

A common misconception is that a vacuum creates an inward-pulling force. In reality, a vacuum is a space with very low pressure and density.

The "collapsing" force is the pressure of the atmosphere outside the retort—approximately 14.7 pounds per square inch (psi) or over 10,000 kg per square meter at sea level—pushing inward on the walls.

The Force is Enormous

This atmospheric pressure is relentless and uniformly applied to the entire surface of the retort. For a medium-sized retort, the total compressive force can easily equal the weight of several cars.

The Compounding Effect of Heat

This structural challenge is magnified at the high operating temperatures of a furnace. Metals lose a significant portion of their mechanical strength and stiffness when heated, making them more susceptible to deformation, creep, and buckling under this constant external load.

Engineering Solutions for Retort Integrity

To counteract these forces, retorts are not simple cylinders. They incorporate specific design features to enhance their structural rigidity.

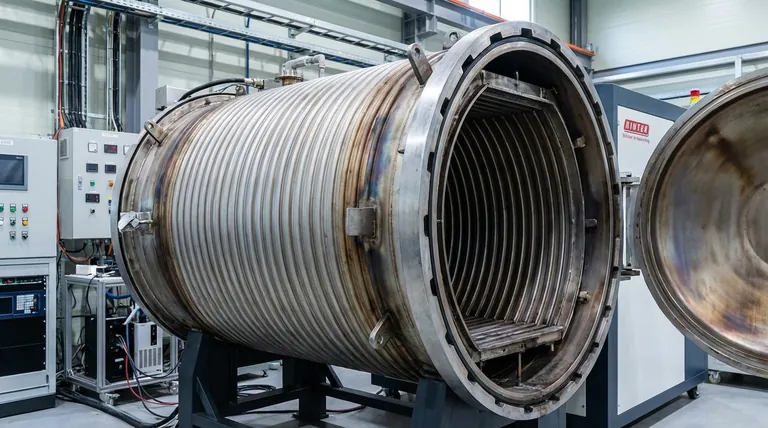

Corrugation: The "Accordion" Principle

Many retorts feature corrugated, or "accordion-style," walls. This seemingly simple design dramatically increases the retort's stiffness and resistance to buckling without significantly increasing its wall thickness or weight.

The folds break up large, flat surfaces, which are inherently weak against uniform compressive loads, distributing the stress much more effectively.

External Reinforcement Rings

Another common method is welding heavy-duty rings, or "stiffeners," to the exterior of the retort at regular intervals.

These rings act like the hoops on a wooden barrel. They provide rigid support and prevent the cylindrical walls from deforming inward into an oval shape, which is the first step in a catastrophic buckling failure.

Increased Wall Thickness

The most straightforward solution is simply to use a thicker metal plate for the retort wall. While effective, this approach has significant downsides, making it a solution of last resort or one used in conjunction with other methods.

Understanding the Trade-offs

Choosing a retort design is a balance of competing engineering priorities. There is no single "best" solution, only the one that is most appropriate for a given application.

Strength vs. Thermal Performance

A thicker or more heavily reinforced retort is stronger, but it also has greater thermal mass. This means it requires more energy and time to heat up and cool down, reducing the furnace's overall efficiency and cycle time.

Reinforcement Rings vs. Temperature Uniformity

External reinforcement rings can act as heat sinks, creating cooler spots on the retort wall. This can negatively impact the temperature uniformity of the process zone inside, a critical factor for many heat-treating applications.

Corrugations vs. Usable Space

While structurally efficient, corrugations slightly reduce the smooth, usable internal diameter of the retort. They can also make cleaning more difficult and may trap contaminants in certain processes.

Making the Right Choice for Your Application

The optimal retort design depends entirely on your primary process requirements.

- If your primary focus is rapid thermal cycling and efficiency: A lighter-weight, corrugated retort is often the superior choice, as its lower thermal mass allows for faster heating and cooling.

- If your primary focus is maximum durability for large, heavy loads: A thick-walled retort combined with external reinforcement rings provides the highest level of structural integrity.

- If your primary focus is absolute temperature uniformity: A straight-walled retort with carefully engineered reinforcement may be necessary, accepting the trade-off in wall thickness and thermal mass.

By understanding these core design principles, you can select a furnace retort that is not just fundamentally safe, but is also optimized for your specific performance and processing goals.

Summary Table:

| Design Feature | Purpose | Key Benefit |

|---|---|---|

| Corrugated Walls | Increase stiffness and prevent buckling | Lightweight, efficient for rapid thermal cycling |

| External Reinforcement Rings | Add support to resist deformation | High durability for heavy loads |

| Increased Wall Thickness | Enhance structural strength | Maximum integrity, but higher thermal mass |

Optimize your furnace retort for superior performance and safety! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need rapid thermal cycling, maximum durability, or precise temperature control, we can design a retort that fits your needs. Contact us today to discuss how we can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics