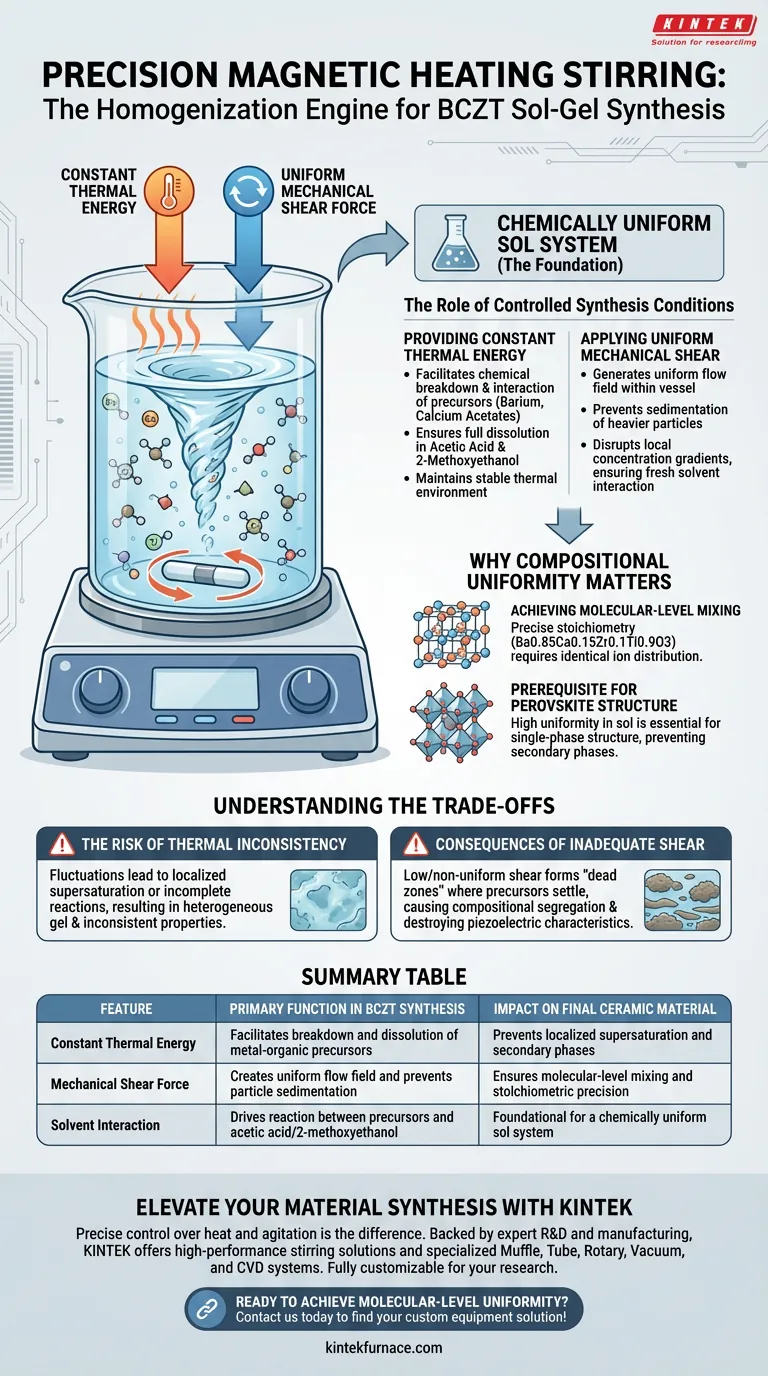

Precision magnetic heating stirring equipment acts as the critical homogenization engine during the chemical synthesis stage of BCZT ceramic preparation. By simultaneously providing constant thermal energy and uniform mechanical shear force, it drives the complete dissolution of metal-organic precursors—specifically barium acetate and calcium acetate—within solvents like acetic acid and 2-methoxyethanol. This controlled environment ensures the creation of a chemically uniform sol system, which is the foundational step for subsequent ceramic processing.

The primary function of this equipment is to guarantee high chemical composition uniformity through precise heat and agitation. This uniformity is a strict prerequisite for achieving the single-phase perovskite structure essential to the final ceramic's performance.

The Role of Controlled Synthesis conditions

Providing Constant Thermal Energy

In the sol-gel process, temperature stability is non-negotiable. Precision heating equipment maintains a constant thermal environment throughout the synthesis.

This steady energy input is required to facilitate the chemical breakdown and interaction of the metal-organic precursors. It ensures that components like barium and calcium acetates dissolve fully into the acetic acid and 2-methoxyethanol solvent system.

Applying Uniform Mechanical Shear

Mere stirring is insufficient; the process requires consistent mechanical shear force. The magnetic stirring mechanism generates a uniform flow field within the reaction vessel.

This shear force prevents the sedimentation of heavier particles and disrupts local concentration gradients. It ensures that fresh solvent continuously interacts with the precursor materials, accelerating the dissolution process.

Why Compositional Uniformity Matters

Achieving Molecular-Level Mixing

The ultimate goal of using this equipment is to move beyond macroscopic blending to achieve mixing at the molecular level.

Because BCZT ceramics rely on a precise stoichiometry (Ba0.85Ca0.15Zr0.1Ti0.9O3), the distribution of ions must be identical throughout the solution. The equipment ensures that Barium, Calcium, Zirconium, and Titanium sources are dispersed perfectly evenly.

Prerequisite for Perovskite Structure

The quality of the final powder is determined during this liquid phase.

A high degree of chemical composition uniformity in the sol system is the specific prerequisite for obtaining a single-phase perovskite structure later in the process. Without this homogeneity, the material may develop secondary phases or impurities during calcination.

Understanding the Trade-offs

The Risk of Thermal Inconsistency

If the heating element fails to provide constant energy, dissolution becomes patchy.

Fluctuations in temperature can lead to localized supersaturation or incomplete reactions. This results in a heterogeneous gel which, even after drying and sintering, will yield ceramics with inconsistent electrical properties.

Consequences of Inadequate Shear

If the mechanical shear force is too low or non-uniform, "dead zones" can form within the mixing vessel.

In these zones, precursors may settle or cluster rather than dissolving. This leads to compositional segregation, where the ratio of Barium to Calcium varies across the material, destroying the desired piezoelectric characteristics of the final BCZT ceramic.

Making the Right Choice for Your Goal

To maximize the effectiveness of your sol-gel preparation, align your equipment usage with your specific quality targets:

- If your primary focus is Phase Purity: Prioritize thermal stability to ensure every gram of precursor is fully dissolved, preventing secondary phase formation.

- If your primary focus is Microstructural Homogeneity: Focus on the consistency of the mechanical shear force to ensure molecular-level distribution of all four cation species.

By mastering the variables of heat and shear at this early stage, you secure the structural integrity required for high-performance BCZT ceramics.

Summary Table:

| Feature | Primary Function in BCZT Synthesis | Impact on Final Ceramic Material |

|---|---|---|

| Constant Thermal Energy | Facilitates breakdown and dissolution of metal-organic precursors | Prevents localized supersaturation and secondary phases |

| Mechanical Shear Force | Creates uniform flow field and prevents particle sedimentation | Ensures molecular-level mixing and stoichiometric precision |

| Solvent Interaction | Drives reaction between precursors and acetic acid/2-methoxyethanol | Foundational for a chemically uniform sol system |

Elevate Your Material Synthesis with KINTEK

Precise control over heat and agitation is the difference between a failed experiment and a high-performance BCZT ceramic. Backed by expert R&D and manufacturing, KINTEK offers high-performance stirring solutions alongside our specialized Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are working on sol-gel precursors or high-temperature sintering, our lab equipment is fully customizable to meet your unique research needs.

Ready to achieve molecular-level uniformity? Contact us today to find your custom equipment solution!

Visual Guide

References

- Baoyun Wang, Yongjun Tian. High-temperature structural disorders stabilize hydrous aluminosilicates in the mantle transition zone. DOI: 10.1038/s41467-025-56312-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does the temperature difference contribute to the cracking of the alumina furnace tube? Prevent Cracks for Longer Tube Life

- Why is a high-purity Alumina Crucible required during the annealing of MoS2? Ensure High-Temperature Material Purity

- Why is the use of high-purity graphite crucibles essential? Protect TiC-High Manganese Steel During Sintering

- Why is molybdenum (Mo) selected as the crucible material for the evaporation of NiO-doped Ga2O3? Expert Insights

- Why is the selection of crucibles with specific internal linings necessary? Protect Purity in Superalloy Melting

- What is the function of high-purity graphite molds during SPS of Cu2Se? Essential Tips for Superior Sintering

- What manufacturing processes rely on laboratory furnaces? Precision Heat Treatment for Advanced Materials

- What are the technical considerations for selecting a stainless steel cylindrical vessel? Magnesium Test Chamber Guide