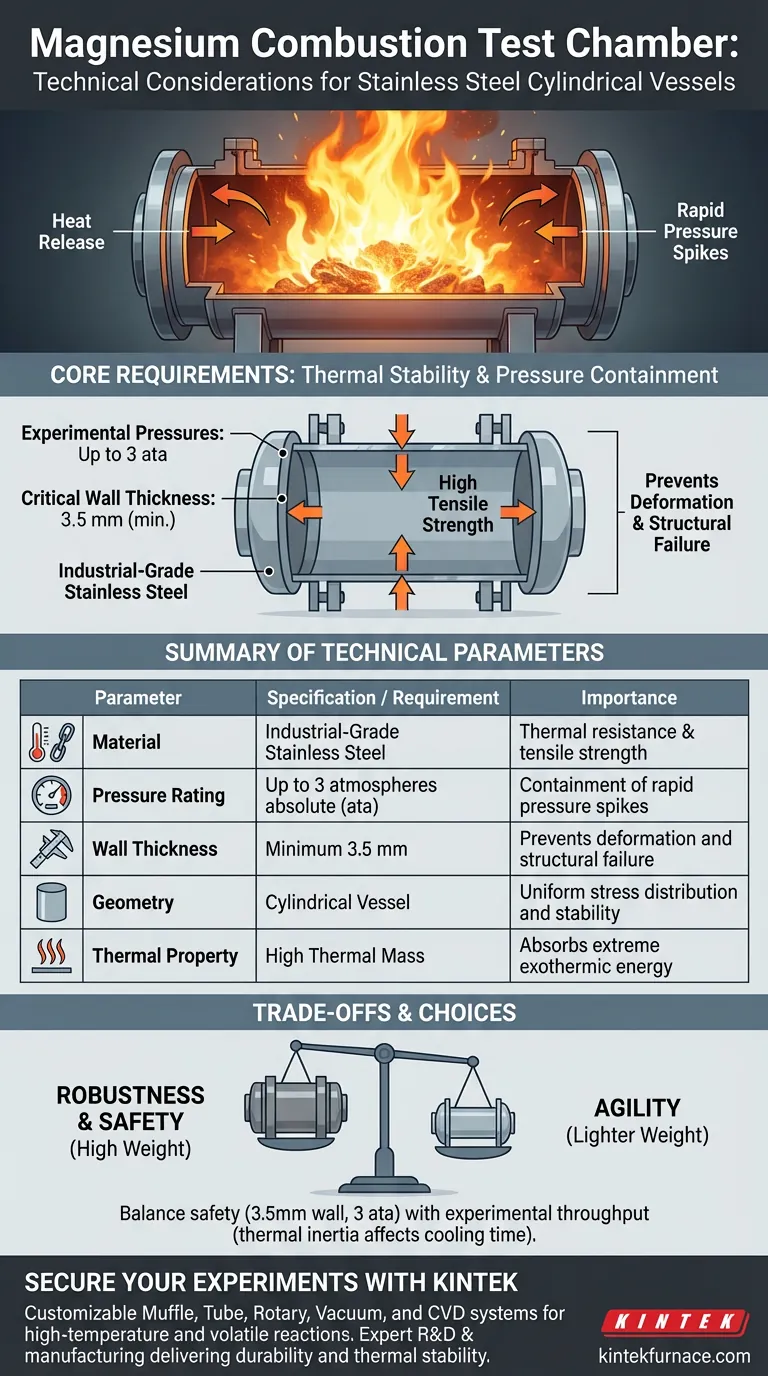

Selecting the right test chamber for magnesium combustion requires prioritizing thermal stability and pressure containment. For this application, an industrial-grade stainless steel cylindrical vessel is essential to withstand the intense exothermic reaction and experimental pressures up to 3 atmospheres absolute (ata), typically necessitating a wall thickness of approximately 3.5 mm to ensure safety.

Magnesium combustion generates violent heat and significant pressure spikes, rendering standard laboratory glassware or softer metals unsafe. The critical requirement is a stainless steel construction with specific geometric reinforcement—such as a 3.5 mm wall thickness—to maintain structural integrity and a stable internal environment under loads up to 3 ata.

Material Properties and Durability

High-Temperature Resistance

Magnesium combustion releases a tremendous amount of energy in the form of heat. The vessel must be constructed from industrial-grade stainless steel to absorb and dissipate this thermal load without warping or losing structural strength.

Pressure Containment Capabilities

The combustion process can rapidly increase internal pressure. The vessel must be rated to handle experimental pressures of at least 3 ata.

Stainless steel provides the high tensile strength necessary to contain these pressure spikes without the risk of rupture, protecting both the operator and the experiment.

Geometric and Structural Design

Critical Wall Thickness

The geometry of the cylinder is just as important as the material itself. To ensure the vessel does not deform under the combined stress of heat and 3 ata pressure, a wall thickness of 3.5 mm is recommended.

This specific thickness creates a safety factor that prevents catastrophic failure during the violent reaction phases.

Controlled Internal Volume

Beyond safety, the vessel design impacts data quality. A controlled internal volume helps maintain a stable environment around the sample.

This stability is crucial for ensuring that the combustion characteristics observed are a result of the fuel properties, not fluctuations in the test environment.

Understanding the Trade-offs

Weight and Portability

The requirement for industrial-grade steel and a 3.5 mm wall thickness significantly increases the weight of the apparatus. This makes the vessel robust but potentially difficult to move or reconfigure compared to lighter, less durable alternatives.

Thermal Inertia

While thick stainless steel protects against structural failure, it also has high thermal mass. The vessel may take longer to cool down after a test, potentially increasing the turnaround time between experimental runs.

Making the Right Choice for Your Project

When finalizing your vessel specifications, balance your safety requirements with your experimental throughput needs.

- If your primary focus is personnel safety: Prioritize the 3.5 mm wall thickness and pressure rating to ensure total containment of the reaction up to 3 ata.

- If your primary focus is experimental consistency: Ensure the internal volume is precisely machined and controlled to maintain a stable environment during combustion.

Select your vessel specs not just for the average operating conditions, but for the peak stress of the reaction.

Summary Table:

| Technical Parameter | Specification / Requirement | Importance in Combustion |

|---|---|---|

| Material | Industrial-Grade Stainless Steel | Thermal resistance & tensile strength |

| Pressure Rating | Up to 3 atmospheres absolute (ata) | Containment of rapid pressure spikes |

| Wall Thickness | Minimum 3.5 mm | Prevents deformation and structural failure |

| Geometry | Cylindrical Vessel | Uniform stress distribution and stability |

| Thermal Property | High Thermal Mass | Absorbs extreme exothermic energy |

Secure Your High-Temperature Experiments with KINTEK

Don't compromise on safety when dealing with volatile reactions like magnesium combustion. Backed by expert R&D and manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific wall thickness and pressure containment needs.

Whether you require a custom stainless steel cylindrical vessel or a high-precision lab furnace, our team delivers the durability and thermal stability your research demands. Contact us today to discuss your unique project requirements and see how our advanced engineering can support your lab's success.

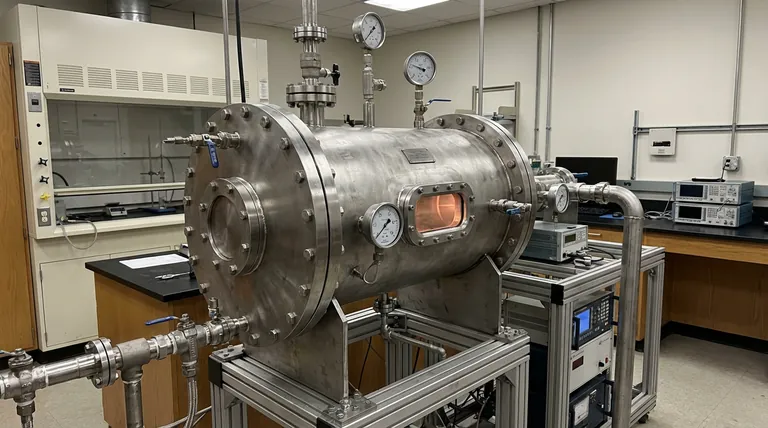

Visual Guide

References

- Ioan Barabulica, Ioan Mămăligă. Experimental Study on the Reaction of Magnesium in Carbon Dioxide and Nitrogen Atmosphere. DOI: 10.3390/chemengineering8020041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a silica crucible selected as the reaction vessel? Ensure Stability and Purity in High-Temp Synthesis

- What technical considerations justify the use of high-purity alumina crucibles for microwave-assisted metal reduction?

- What is the function of a high-pressure stainless steel autoclave? Master Hydrothermal Synthesis of Nanomaterials

- What is the primary function of vacuum quartz tubes in Bi-Sb alloy preparation? Ensure Purity & Precise Stoichiometry

- What are the key properties of quartz tubes that make them versatile across industries? Discover Their Thermal, Chemical, and Optical Benefits

- What are the roles of rotameters and digital flow controllers in pneumatic systems? Enhance Precision and Testing

- What are the core functions of high-purity graphite molds and graphite paper in SPS? Optimize Sintering Quality

- What are the advantages of high-temperature BSE detectors? Unlock Real-Time Compositional Analysis up to 1000°C