The primary function of vacuum quartz tubes is to serve as a hermetically sealed, high-purity containment vessel that creates an anaerobic protective atmosphere. This isolation is essential during the high-temperature melting of Bismuth (Bi) and Antimony (Sb), as it completely effectively prevents the oxidation of these reactive elements. By eliminating exposure to air, the tubes ensure the final alloy maintains precise chemical composition and high purity levels.

The core value of the vacuum quartz tube lies in its ability to enforce a strictly oxygen-free environment during synthesis. This physical isolation preserves the thermodynamic equilibrium of the alloy, ensuring that the final material exhibits the exact stoichiometric ratio intended by the researcher.

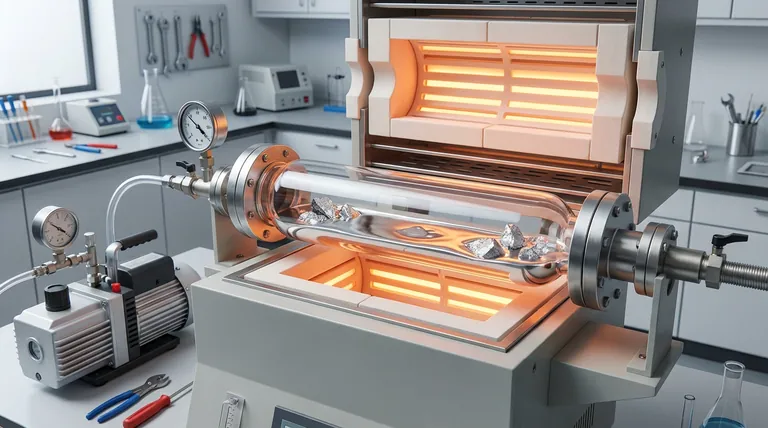

Creating a Controlled Synthesis Environment

Preventing Elemental Oxidation

The most critical risk during the preparation of Bi-Sb alloys is exposure to oxygen at high temperatures. Bismuth and Antimony are susceptible to oxidation when heated, which introduces impurities that degrade the alloy's electronic properties.

The Role of Vacuum Sealing

By sealing the raw materials under high vacuum (often reaching 10^-5 Torr), the quartz tube removes the atmosphere entirely. This creates an anaerobic environment where oxidation is chemically impossible, regardless of the melting duration.

Ensuring Stoichiometric Precision

Beyond preventing oxidation, the sealed environment maintains the correct ratio of elements (stoichiometry). It prevents the loss of volatile elements—which might otherwise evaporate or react with air—ensuring the resulting alloy matches the calculated formulation exactly.

The Role of Quartz as a Container

High-Purity Inert Containment

Quartz is utilized because it functions as a neutral, high-purity vessel. Unlike metal crucibles that might leach impurities into the melt, high-purity quartz remains chemically inert relative to the alloy components.

Thermal Stability

The synthesis of these alloys often requires temperatures reaching 1273 K. Quartz tubes possess the thermal resilience to withstand these extremes without softening or degrading, providing a stable boundary for the molten material.

Understanding the Trade-offs

Strict Vacuum Requirements

The effectiveness of this method is entirely dependent on the quality of the seal. If the internal pressure is not sufficiently reduced (e.g., failing to reach high-vacuum standards), trace oxygen remains, and the protective benefit is compromised.

Scalability Limitations

While quartz tubes are ideal for laboratory-scale synthesis and high-precision annealing, they represent a closed-batch system. Unlike continuous casting or larger Vacuum Induction Melting furnaces, quartz tubes are generally limited to smaller quantities of raw material per run.

Ensuring Material Integrity in Your Process

To achieve the highest quality Bi-Sb alloys, you must align your containment method with your specific purity goals.

- If your primary focus is Absolute Chemical Purity: Prioritize achieving a high-vacuum seal (10^-5 Torr) to completely eliminate oxidation pathways.

- If your primary focus is Compositional Accuracy: Ensure the tube is fully sealed to prevent the volatilization of elements, locking in the stoichiometric ratio.

By treating the quartz tube as an active component in the synthesis—rather than just a holder—you guarantee the structural and chemical fidelity of your final alloy.

Summary Table:

| Feature | Function in Bi-Sb Synthesis | Benefit to Final Alloy |

|---|---|---|

| Vacuum Sealing | Removes oxygen & moisture | Prevents elemental oxidation |

| Hermetic Isolation | Contains volatile elements | Ensures precise chemical stoichiometry |

| High-Purity Quartz | Chemically inert material | Prevents impurity leaching/contamination |

| Thermal Stability | Withstands up to 1273 K | Provides a stable vessel for melting |

Elevate Your Material Synthesis with KINTEK Precision

Don't let oxidation or contamination compromise your research results. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of Bi-Sb alloy preparation and high-temperature laboratory processes.

Ready to achieve absolute chemical purity? Contact us today to discover how our advanced heating solutions and customizable quartz tube systems can optimize your laboratory’s efficiency and material integrity.

References

- Dragan Manasijević, Ivana Marković. Thermal conductivity and microstructure of Bi-Sb alloys. DOI: 10.2298/hemind230829002m

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What materials are used in the construction of a water circulating vacuum pump? Key Components for Durability

- Why is a high-performance vacuum pump system essential for magnesium purification? Achieve High Purity and Efficiency

- How does the hardness of alumina ceramics compare to other materials? Discover Its Superior Wear Resistance

- What core environmental protection does an argon-protected glove box provide for sodium-ion batteries? Maximize Safety

- Why is a heating magnetic stirrer used for the acid activation of zeolites? Precision in Thermal & Kinetic Control

- Why are zirconia grinding jars and milling balls ideal for Bismuth Telluride? Achieve 200nm Purity and Performance

- What are the electrical properties of alumina tubes? Discover Superior Insulation for Extreme Conditions

- Why are high-purity graphite crucibles with lids used for ilmenite reduction? Control Your Micro-Reducing Atmosphere