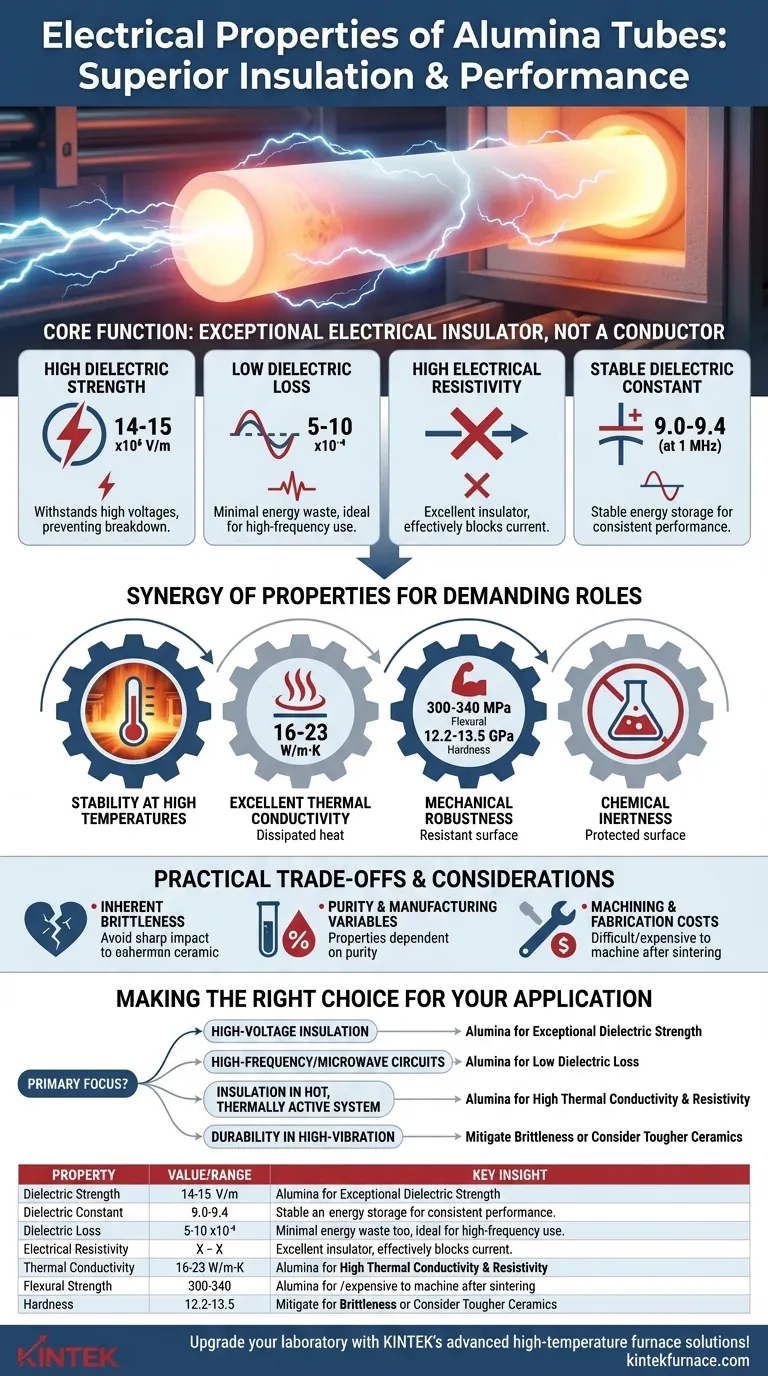

At its core, alumina (aluminum oxide, Al₂O₃) is an exceptional electrical insulator, not a conductor. Its key electrical properties are a high dielectric strength of 14-15 x10⁶ V/m, a stable dielectric constant around 9.0-9.4 (at 1 MHz), and a very low dielectric loss. These characteristics mean it can withstand high voltages without breaking down and wastes very little energy as heat, making it a premier material for demanding electrical applications.

The defining electrical characteristic of an alumina tube is its ability to function as a superior insulator, especially under extreme thermal and chemical stress. Its value comes not just from its electrical properties alone, but from their stability in environments where other materials would fail.

Understanding Alumina's Electrical Insulation Capabilities

Alumina's reputation as a high-performance ceramic is built on its robust electrical properties. Understanding these individual characteristics reveals why it is chosen for critical components.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand a strong electric field without experiencing electrical breakdown and becoming conductive.

With a strength of 14-15 million volts per meter, alumina can insulate against very high voltages, preventing short circuits and component failure. This makes it ideal for high-voltage standoffs, insulators, and electronic substrates.

Low Dielectric Loss

Dielectric loss refers to the inherent dissipation of energy when an insulating material is subjected to an alternating electric field. This lost energy typically manifests as heat.

Alumina's very low loss angle (5-10 x10⁻⁴) means it wastes minimal energy, a critical attribute in high-frequency applications like microwave tubes and communication components where efficiency and thermal management are paramount.

High Electrical Resistivity

Resistivity is the fundamental measure of how strongly a material opposes the flow of electric current. As a ceramic, alumina has exceptionally high electrical resistivity.

This property is the essence of its function as an insulator. It effectively blocks current flow, ensuring electrical isolation between conductive parts of a system.

Stable Dielectric Constant

The dielectric constant indicates a material's ability to store electrical energy when placed in an electric field. Alumina has a relatively high and stable constant of 9.0-9.4.

This stability and predictability are crucial for designers of capacitors and high-frequency circuits, as it ensures consistent performance across a range of conditions.

The Synergy of Properties: Why Alumina Excels in Demanding Roles

The true value of alumina is not in any single property but in the combination of its electrical, thermal, and mechanical strengths. This synergy allows it to perform in conditions where few other materials can.

Stability at High Temperatures

Many materials lose their insulating properties as temperatures rise. Alumina, however, maintains its high electrical resistivity and dielectric strength even at extreme temperatures, making it a default choice for furnace components, thermocouple tubes, and heating element supports.

Excellent Thermal Conductivity

Unlike most electrical insulators which are also thermal insulators, alumina has good thermal conductivity (16-23 W/m·K).

This unique combination allows it to act as an electrical insulator while simultaneously dissipating heat. This prevents the overheating of sensitive electronic components mounted on alumina substrates.

Mechanical Robustness

With a high flexural strength (300-340 MPa) and hardness (12.2-13.5 GPa), alumina is a mechanically strong and wear-resistant material.

This means an alumina insulator will not just perform electrically but will also withstand physical abrasion, compression, and wear over its service life.

Chemical Inertness

Alumina exhibits excellent resistance to corrosion from a wide range of chemicals, even at high temperatures. This ensures its physical and electrical integrity is not compromised in harsh industrial or chemical processing environments.

Understanding the Practical Trade-offs

No material is without its limitations. Objectivity requires acknowledging the trade-offs associated with using alumina.

Inherent Brittleness

Like most ceramics, alumina is brittle. It has low fracture toughness, meaning it can fail suddenly under sharp impact or high tensile stress.

Designers must account for this by avoiding sharp corners and protecting components from mechanical shock and severe thermal shock (rapid temperature changes).

Purity and Manufacturing Variables

The stated properties, particularly electrical ones, are highly dependent on the purity and density of the alumina. A 99.7% pure alumina will have different—and generally superior—properties compared to a 94% pure variant.

The manufacturing process, including sintering temperature and pressure, plays a critical role in the final performance of the component.

Machining and Fabrication Costs

Due to its extreme hardness, alumina is very difficult and expensive to machine after it has been sintered. Complex shapes must be formed during the initial "green" stage before firing.

This requires careful design and planning, as post-sintering modifications are often impractical.

Making the Right Choice for Your Application

Your final decision should be guided by your most critical performance requirement.

- If your primary focus is high-voltage insulation in a stable environment: Alumina's exceptional dielectric strength makes it a leading candidate.

- If your primary focus is high-frequency or microwave circuits: Its low dielectric loss is essential for minimizing energy waste and heat buildup.

- If your primary focus is insulation in a hot, thermally active system: Alumina's unique blend of high thermal conductivity and electrical resistivity is its most powerful advantage.

- If your primary focus is durability in a high-vibration or impact-prone setting: You must design carefully to mitigate its brittleness or consider a tougher ceramic like zirconia.

Ultimately, alumina is the material of choice when you require unwavering electrical insulation in environments too extreme for polymers or lesser ceramics.

Summary Table:

| Property | Value/Range | Key Insight |

|---|---|---|

| Dielectric Strength | 14-15 x10⁶ V/m | Withstands high voltages, preventing breakdown |

| Dielectric Constant | 9.0-9.4 (at 1 MHz) | Stable energy storage for consistent performance |

| Dielectric Loss | 5-10 x10⁻⁴ | Minimal energy waste, ideal for high-frequency use |

| Electrical Resistivity | Very high | Excellent insulator, blocks current flow effectively |

| Thermal Conductivity | 16-23 W/m·K | Dissipates heat while insulating electrically |

| Flexural Strength | 300-340 MPa | Mechanically robust for durability in harsh environments |

| Hardness | 12.2-13.5 GPa | Resists wear and abrasion over time |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your needs. Our deep customization capabilities ensure precise alignment with your unique experimental requirements, delivering reliable insulation and performance in extreme conditions. Don't let material limitations hold you back—contact us today to discuss how our solutions can enhance your efficiency and results!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab