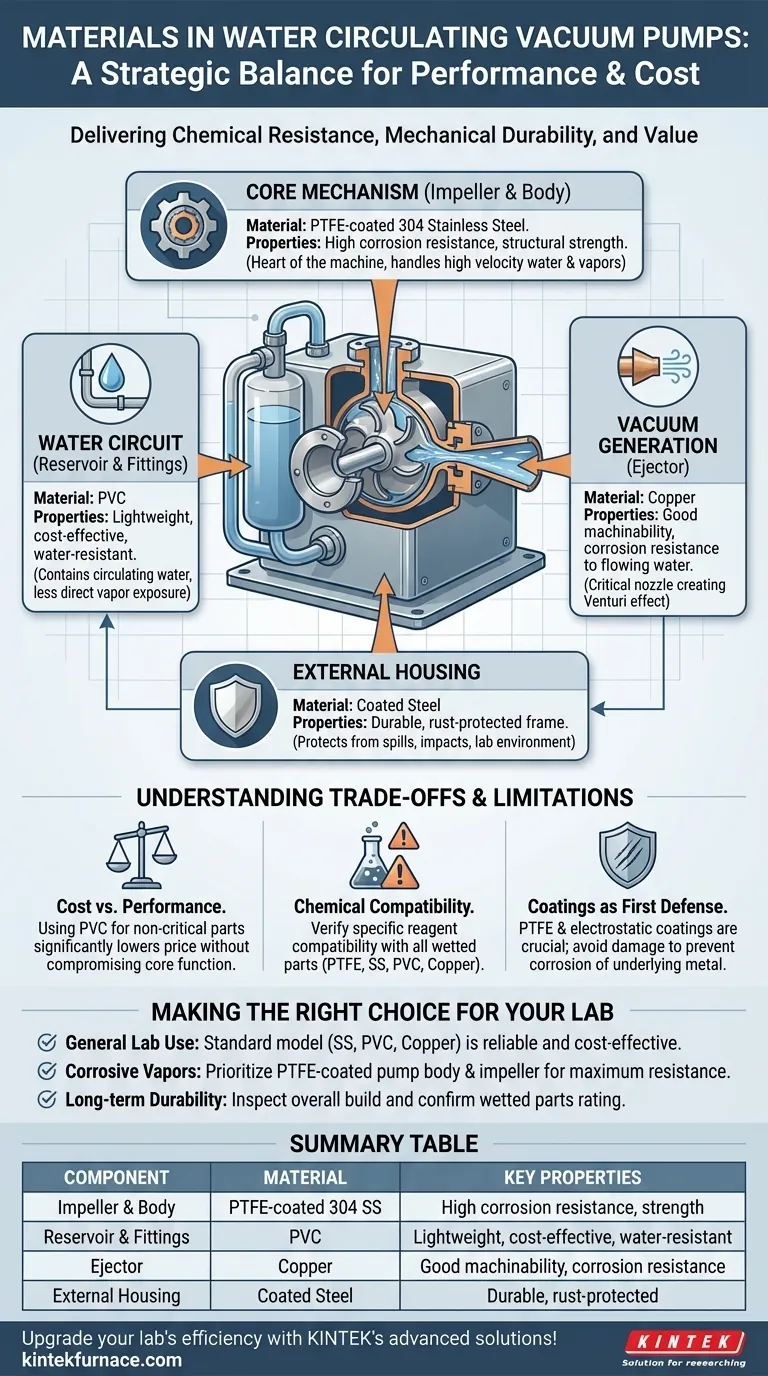

The construction of a water circulating vacuum pump relies on a strategic combination of metals, polymers, and specialized coatings. Core components like the pump body and impeller are typically made from PTFE-coated 304 stainless steel, while the water reservoir and fittings often use PVC. Other critical parts, like the ejector, may be made from copper, and the external housing is usually coated steel.

The choice of materials in a vacuum pump is a deliberate balance of chemical resistance, mechanical durability, and cost. The most robust and inert materials are reserved for components in direct contact with potentially corrosive vapors, while more economical materials are used for less critical parts like the water tank and external housing.

A Component-by-Component Material Analysis

Understanding the function of each part reveals why specific materials are chosen. The design prioritizes placing the strongest defense where the chemical and mechanical stress is highest.

The Core Pump Mechanism: Impeller and Body

The impeller and pump body are the heart of the machine, responsible for moving the water at high velocity. These components are in constant contact with the circulating water and any vapors pulled into the system.

For this reason, they are typically constructed from 304 stainless steel. This alloy provides excellent structural strength and good baseline resistance to corrosion from water and many common chemicals.

To handle more aggressive lab environments, the stainless steel is often coated with PTFE (Polytetrafluoroethylene). This coating is exceptionally inert, providing a superior barrier against acidic gases and corrosive vapors that would otherwise damage the steel over time.

The Water Circuit: Reservoir and Fittings

The water reservoir, suction nozzles, TEE adapters, and check valves form the system's plumbing. These parts contain the circulating water but have less direct exposure to the vacuum process vapors.

These components are commonly made from PVC (Polyvinyl Chloride). PVC is an ideal choice here because it is lightweight, inexpensive, and completely resistant to corrosion from water. It also handles a wide range of dissolved salts and mild chemicals without degrading.

The Vacuum Generation: Ejector

The ejector is a critical nozzle where the high-speed stream of water passes, creating the Venturi effect that generates the vacuum.

This component is often made of copper. Copper offers good machinability for creating the precise nozzle shape required, along with excellent resistance to corrosion from flowing water.

The External Housing

The outer casing protects the internal mechanics from spills, impacts, and the general lab environment.

It is typically a cold-plate steel housing with an electrostatic spray coating. This construction provides a durable, rigid frame for the pump while the coating protects the steel from rust and minor chemical exposure.

Understanding Material Trade-offs and Limitations

The material choices are not without compromises. Understanding these trade-offs is crucial for selecting the right pump and ensuring its longevity.

Why Not Use Stainless Steel for Everything?

Cost is the primary driver. While a pump made entirely of PTFE-coated stainless steel would be incredibly robust, it would also be prohibitively expensive. Using cost-effective PVC for the tank and fittings significantly lowers the price without compromising the core function for most applications.

The Importance of Chemical Compatibility

"Corrosion-resistant" does not mean universally immune. The PTFE coating provides a powerful defense, but it can be compromised by certain aggressive solvents or physical damage. Likewise, the copper ejector can be attacked by chemicals like ammonia or strong acids.

Always verify the compatibility of your specific reagents with all the pump's wetted materials—PTFE, stainless steel, PVC, and copper.

The Role of Coatings as the First Defense

Coatings like PTFE and the electrostatic spray on the housing are the first line of defense. If this layer is scratched or damaged by abrasive particles in the water or improper cleaning, the underlying metal is exposed and becomes vulnerable to corrosion.

Making the Right Choice for Your Application

Use your knowledge of these materials to select a pump that aligns with your specific laboratory needs.

- If your primary focus is general lab use with water or mild solvents: A standard model with stainless steel, PVC, and copper components offers a reliable and cost-effective solution.

- If your primary focus is working with highly corrosive or acidic vapors: Prioritize models that explicitly feature a PTFE coating on the stainless steel pump body and impeller for maximum chemical resistance.

- If your primary focus is long-term durability: Inspect the overall build quality, including a robust housing, and confirm that all wetted parts are rated for your typical chemical workload.

Understanding the materials that make up your equipment is the first step toward ensuring its long-term reliability and the success of your work.

Summary Table:

| Component | Material | Key Properties |

|---|---|---|

| Impeller & Body | PTFE-coated 304 Stainless Steel | High corrosion resistance, structural strength |

| Reservoir & Fittings | PVC | Lightweight, cost-effective, water-resistant |

| Ejector | Copper | Good machinability, corrosion resistance |

| External Housing | Coated Steel | Durable, rust-protected |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how we can enhance your processes and deliver superior performance!

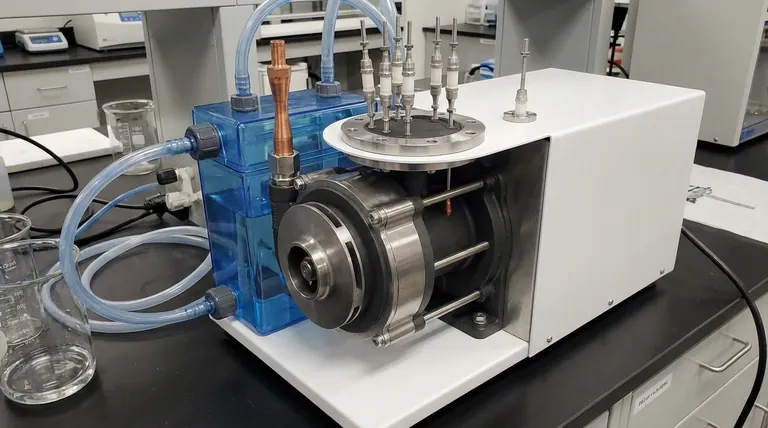

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a quartz tube selected as the sample container for emissivity measurement? Precision Microwave Heating Benefits

- Why are graphite crucible furnaces used in vacuum or protective atmosphere environments? Prevent Oxidation and Ensure Purity

- How does a vacuum pump facilitate the pre-treatment of modified multi-walled carbon nanotubes? Optimize Surface Activation

- Why are corundum or ceramic crucibles required for high-temperature magnesium evaporation processes? Ensure Purity and Prevent Crucible Failure

- What is the recommended cooling rate for the alumina furnace tube? Prevent Thermal Shock and Extend Tube Life

- What are quartz tubes used for? Essential for High-Temperature, High-Purity Applications

- What technical considerations justify the use of high-purity alumina crucibles for microwave-assisted metal reduction?

- Why are high-purity quartz tubes and quartz boats preferred for plastic pyrolysis? Ensure Precise, Pure Results