Zirconia grinding jars and milling balls are the preferred choice for processing Bismuth Telluride primarily due to their extreme hardness and superior chemical inertness. These physical characteristics drastically minimize the wear rate of the grinding media, preventing the introduction of impurities into the nanopowder. Consequently, this maintains the chemical purity necessary for the material's thermoelectric applications while facilitating particle reduction to the nanometer scale.

Any milling process involves high-energy impact, but preserving the purity of Bismuth Telluride is critical for its performance. Zirconia’s resistance to physical wear ensures that the grinding media itself does not degrade and contaminate the batch during the reduction to 200nm.

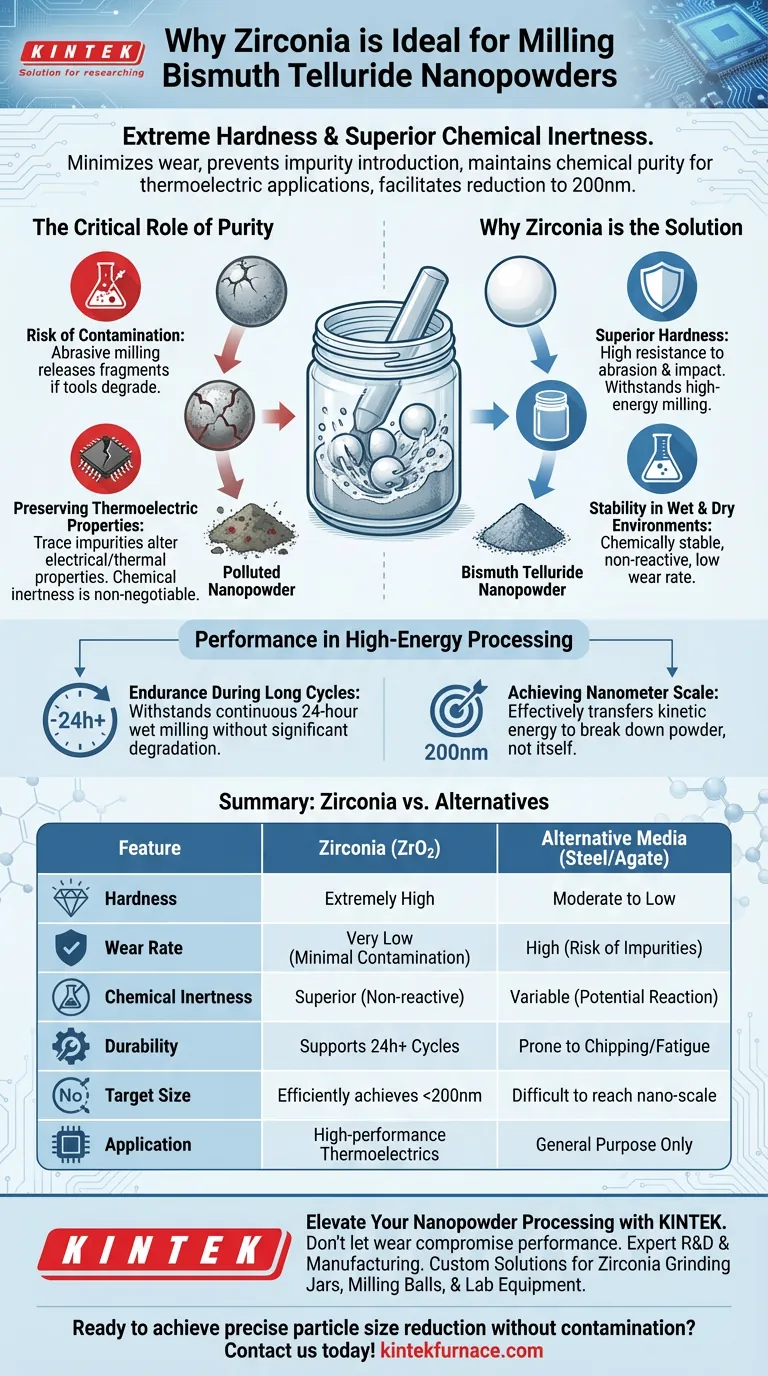

The Critical Role of Purity in Milling

The Risk of Contamination

Milling is an abrasive process where grinding balls constantly collide with the jar walls and the material being processed.

If the grinding tools are not hard enough, they will degrade. This releases microscopic fragments of the jar or ball material into your Bismuth Telluride powder.

Preserving Thermoelectric Properties

Bismuth Telluride relies on precise chemical composition to function as an effective thermoelectric material.

Even trace amounts of foreign impurities from worn grinding media can alter its electrical and thermal properties. Therefore, the chemical inertness of the milling media is non-negotiable.

Why Zirconia is the Solution

Superior Hardness

Zirconia is exceptionally hard, which provides high resistance to abrasion and impact.

This allows it to withstand the mechanical stresses of high-energy milling without chipping or wearing down.

Stability in Wet and Dry Environments

The material is chemically stable, meaning it will not react with Bismuth Telluride or the solvents used in wet milling.

This makes it versatile for different processing methodologies while maintaining a low wear rate.

Performance in High-Energy Processing

Endurance During Long Cycles

Reducing materials to the nanoscale requires prolonged processing times.

Zirconia components have proven capable of withstanding continuous 24-hour wet milling cycles without significant degradation.

Achieving Nanometer Scale

To reduce Bismuth Telluride to a particle size of approximately 200nm, significant kinetic energy is required.

Zirconia media effectively transfers this energy to the powder to break it down, rather than absorbing the energy and breaking itself.

Understanding the Risks of Alternatives

The Consequence of High Wear Rates

Using softer grinding media (such as stainless steel or agate) in high-energy mills often results in a high wear rate.

This physical degradation leads to "impurity contamination," effectively ruining the batch for sensitive applications.

Physical Impact Damage

Grinding media that lacks the toughness of Zirconia is prone to surface fatigue.

This can result in larger chips or flakes entering the mixture, which are difficult to separate from the desired nanopowder.

Making the Right Choice for Your Goal

To ensure the success of your Bismuth Telluride processing, align your equipment choice with your specific technical requirements:

- If your primary focus is Chemical Purity: Choose Zirconia to eliminate the risk of wear-induced contamination interfering with thermoelectric performance.

- If your primary focus is Particle Size Reduction: Rely on Zirconia to sustain the high-energy impacts required to reach 200nm without media failure.

By selecting Zirconia, you ensure that the physical reduction of your material does not come at the cost of its chemical integrity.

Summary Table:

| Feature | Zirconia (ZrO2) | Alternative Media (Steel/Agate) |

|---|---|---|

| Hardness | Extremely High | Moderate to Low |

| Wear Rate | Very Low (Minimal Contamination) | High (Risk of Impurities) |

| Chemical Inertness | Superior (Non-reactive) | Variable (Potential Reaction) |

| Durability | Supports 24h+ Milling Cycles | Prone to Chipping/Surface Fatigue |

| Target Size | Efficiently achieves <200nm | Difficult to reach nano-scale |

| Application | High-performance Thermoelectrics | General Purpose Only |

Elevate Your Nanopowder Processing with KINTEK

Don't let media wear compromise your Bismuth Telluride’s thermoelectric performance. At KINTEK, we understand that chemical purity is non-negotiable for advanced materials.

Backed by expert R&D and manufacturing, we provide high-performance Zirconia grinding jars, milling balls, and specialized laboratory equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique lab requirements.

Ready to achieve precise particle size reduction without contamination? Contact us today to find your custom solution!

Visual Guide

References

- Mohamed Abdelnaser Mansour, Ahmed Abdelmoneim. Enhancing the thermoelectric properties for hot-isostatic-pressed Bi2Te3 nano-powder using graphite nanoparticles. DOI: 10.1007/s10854-024-12389-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the advantages of using a Boron Nitride crucible? Maximize Purity and Efficiency in Laser Pyrolysis

- What roles do high-purity graphite molds play during the Spark Plasma Sintering (SPS) of Ba0.95La0.05FeO3-δ? Essential Guide

- What role does a PTFE-lined high-pressure autoclave play in synthesis of ZnO nanorods? Key Benefits & Growth Factors

- What are the technical advantages of using ZrO2 crucibles? Elevate Smelting Accuracy with Zirconium Dioxide

- What function does a planetary ball mill perform in LiFePO4/C synthesis? Optimize Battery Material Conductivity

- What is the function of high-vacuum quartz sealing tubes in TiCo1-xCrxSb heat treatment? Ensure Alloy Purity

- What role do quartz tubes and vacuum sealing play in synthesis? Master High-Reactivity Compounds like U0.92Mn3Si2C

- Why is a high-precision Mass Flow Controller necessary for E-Ni/m-MgAlOx catalysts? Ensure Precise Gas Dynamics