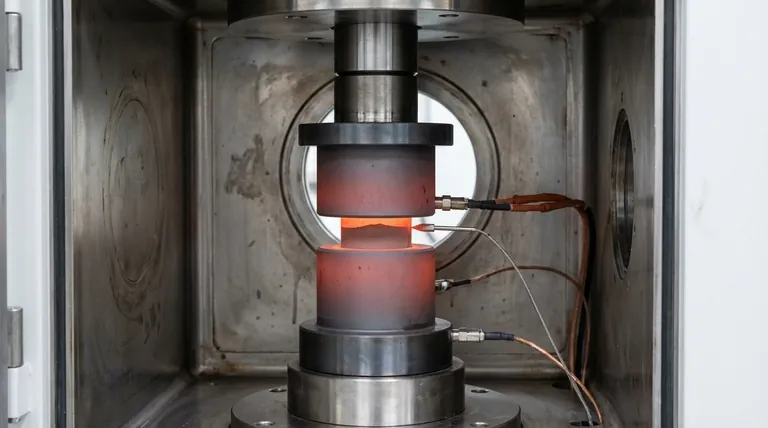

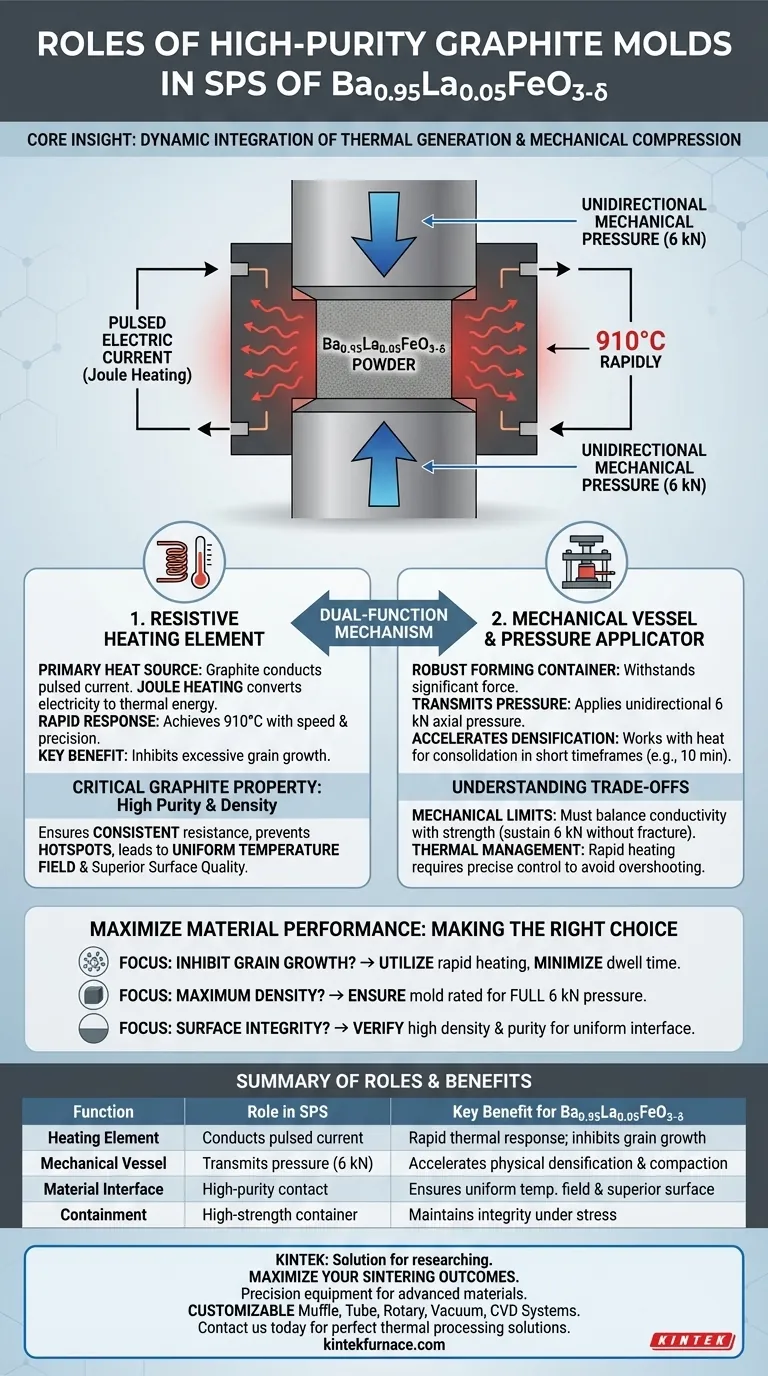

In the Spark Plasma Sintering (SPS) of Ba0.95La0.05FeO3-δ, high-purity graphite molds function as both the mechanical vessel and the active heating element. These molds are designed to hold the powder sample while simultaneously applying a specific mechanical pressure of 6 kN. Furthermore, they utilize their intrinsic electrical resistance to convert electrical energy directly into heat, ensuring a rapid thermal response throughout the sintering cycle.

Core Insight: The graphite mold is not merely passive tooling; it is a dynamic component that integrates thermal generation with mechanical compression. This dual functionality is critical for achieving rapid densification while inhibiting the excessive grain growth and component volatilization often seen in conventional sintering.

The Dual-Function Mechanism

Acting as a Resistive Heating Element

Unlike conventional furnaces that heat from the outside in, the graphite mold serves as the primary heat source. Due to its excellent electrical conductivity, the mold allows pulsed electric currents to pass through it.

This process converts electrical current into thermal energy via Joule heating. This mechanism enables the system to reach and maintain high temperatures (such as 910°C) with exceptional speed and precision.

Applying Mechanical Pressure

The mold functions as a robust forming container capable of withstanding significant force. During the processing of Ba0.95La0.05FeO3-δ, it transmits a unidirectional mechanical pressure of 6 kN to the powder.

This axial pressure is essential for physical compaction. It works in tandem with the heat to accelerate densification, allowing the material to consolidate fully in short timeframes (e.g., 10 minutes).

Critical Material Properties

The Importance of Graphite Purity

The efficacy of the SPS process relies heavily on the purity and density of the graphite used. These material characteristics directly dictate the uniformity of the temperature field generated within the mold.

High-purity graphite ensures that the electrical resistance is consistent throughout the mold body. This prevents localized hotspots that could lead to uneven sintering or structural defects in the final composite.

Impact on Surface Quality

Beyond internal densification, the mold interface determines the exterior finish of the sample. High-quality graphite molds result in a superior final surface quality of the Ba0.95La0.05FeO3-δ composite.

Understanding the Trade-offs

Mechanical Limitations vs. Conductivity

While graphite offers excellent conductivity, it has mechanical limits. The mold must be strong enough to transmit 6 kN of pressure, but it is not infinitely durable; excessive pressure or thermal shock can lead to fracture.

Thermal Environment Management

The rapid heating provided by the graphite mold is highly efficient, but it creates a specific thermal environment. While it prevents the phase transformations associated with long-term sintering, the rapid temperature response requires precise control to avoid overshooting target temperatures like 910°C.

Making the Right Choice for Your Goal

To maximize the quality of your Ba0.95La0.05FeO3-δ samples, align your process parameters with the mold's capabilities:

- If your primary focus is inhibiting grain growth: Utilize the mold's ability to heat rapidly to minimize dwell time (aim for roughly 10 minutes at 910°C).

- If your primary focus is maximum density: Ensure the mold is rated to sustain the full 6 kN of axial pressure without deformation to ensure uniform compaction.

- If your primary focus is surface integrity: Verify the density and purity grade of your graphite tooling to ensure a uniform temperature field and smooth contact interface.

Leveraging the active roles of the graphite mold transforms sintering from a passive heating process into a precise, multi-physics manufacturing technique.

Summary Table:

| Function | Role in SPS Process | Key Benefit for Ba0.95La0.05FeO3-δ |

|---|---|---|

| Heating Element | Conducts pulsed current for Joule heating | Rapid thermal response at 910°C; inhibits grain growth |

| Mechanical Vessel | Transmits unidirectional pressure (6 kN) | Accelerates physical densification & compaction |

| Material Interface | High-purity/density graphite contact | Ensures uniform temperature field & superior surface finish |

| Containment | High-strength forming container | Maintains structural integrity under thermal/mechanical stress |

Maximize Your Material Performance with KINTEK

Precision in Spark Plasma Sintering starts with superior equipment. Whether you are processing advanced ceramics like Ba0.95La0.05FeO3-δ or developing new composites, KINTEK provides the high-performance solutions you need.

Backed by expert R&D and manufacturing, we offer specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique research and production requirements.

Ready to elevate your sintering outcomes? Contact us today to consult with our experts and find the perfect thermal processing solution for your laboratory.

Visual Guide

References

- Christian Berger, Rotraut Merkle. Ion transport in dry and hydrated Ba<sub>0.95</sub>La<sub>0.05</sub>(Fe<sub>1−<i>x</i></sub>Y<sub><i>x</i></sub>)O<sub>3−<i>δ</i></sub> and implications for oxygen electrode kinetics of protonic ceramic cells. DOI: 10.1039/d5ta03014e

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is a vacuum filtration system necessary before evaluating activated carbon microspheres? Ensure Reliable Test Data

- What are the benefits of a vacuum chamber? Achieve Unmatched Process Control and Purity

- Why is a high-purity graphite crucible essential for magnesium vacuum distillation? Achieve Maximum Purity & Efficiency

- Why must a rotary vane vacuum pump be integrated into the curing platform for phenolic laminates? Key to Void-Free Parts

- Why is a standard Quartz Crystal Sensor required during germanium evaporation for nanocrystal fabrication?

- What role does a high-density MgO crucible play in slag reduction experiments? Ensure Pure Results at 1600°C

- How has the circulating water vacuum pump been received in practical use? Durable, Cost-Effective for Lab Tasks

- What is the function of a water quenching tank? Capturing Microstructures in Weather-Resistant Steel