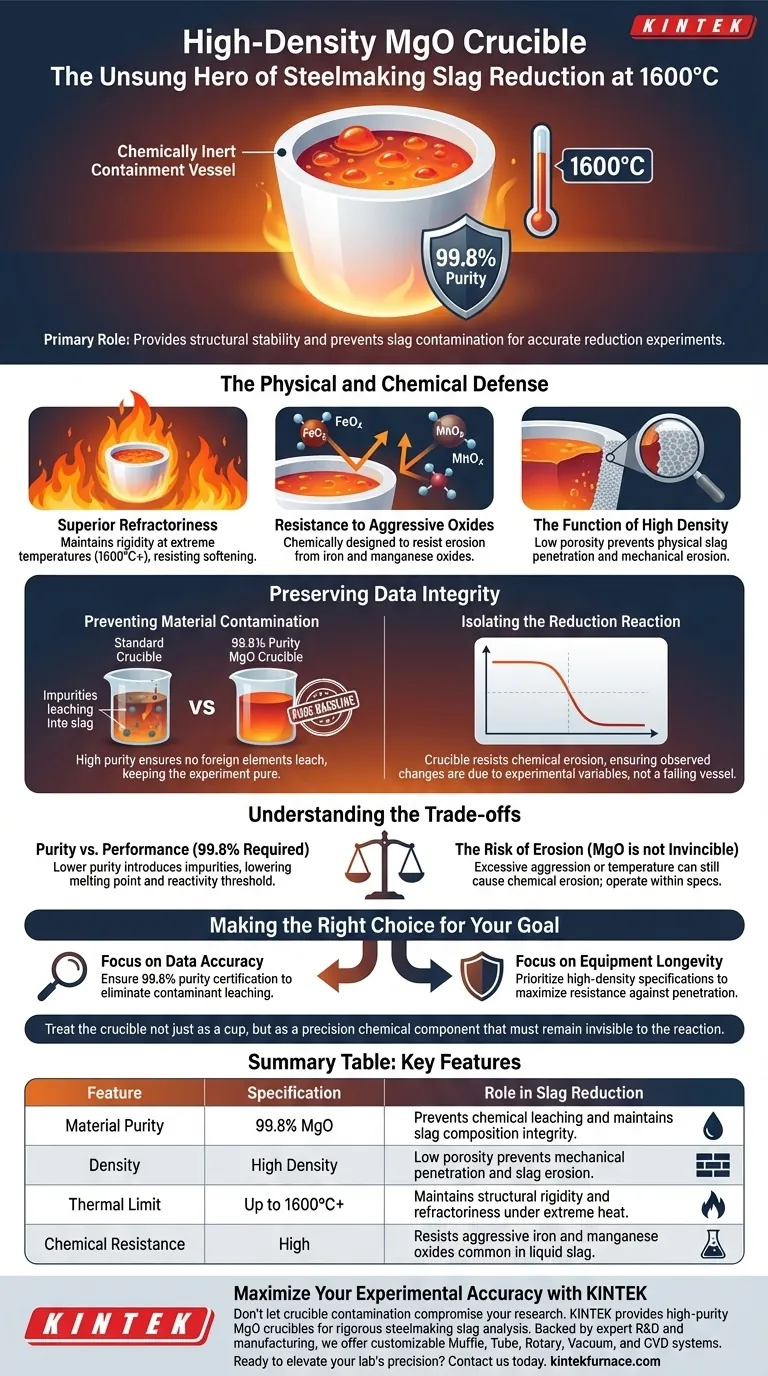

The primary role of a high-density Magnesium Oxide (MgO) crucible in these experiments is to serve as a chemically inert containment vessel. Operating at extreme temperatures of 1600°C, it provides the necessary structural stability to hold liquid steelmaking slag. Crucially, its high purity (99.8%) prevents the crucible itself from reacting with the slag, ensuring that the experimental results reflect only the intended reduction reactions.

The high-density MgO crucible solves the problem of "container contamination." By resisting erosion from aggressive oxides, it ensures that the chemistry of the crucible does not alter the composition of the slag, guaranteeing reliable and accurate experimental data.

The Physical and Chemical Defense

The choice of material for a reaction vessel at 1600°C is not just about heat resistance; it is about survival against chemical attack.

Superior Refractoriness

At 1600°C, many standard refractory materials would soften or melt. Magnesium Oxide is selected specifically for its superior refractoriness, allowing it to maintain rigidity and structural integrity even when holding molten slag at these extreme temperatures.

Resistance to Aggressive Oxides

Liquid steelmaking slag contains highly corrosive elements. The MgO crucible is chemically designed to resist erosion from iron oxide and manganese oxide, which are notoriously aggressive toward containment materials.

The Function of High Density

The "high-density" specification is critical to the vessel's performance. High density implies low porosity, which physically prevents the liquid slag from penetrating the crucible walls, thereby stopping mechanical erosion that often accompanies chemical attack.

Preserving Data Integrity

The ultimate goal of using high-purity MgO is to protect the validity of the scientific data being collected.

Preventing Material Contamination

In reduction experiments, even trace amounts of dissolved crucible material can skew results. By utilizing 99.8% purity MgO, researchers ensure that no foreign elements leach into the slag, keeping the chemical baseline of the experiment pure.

Isolating the Reduction Reaction

The experiment aims to measure the reduction of the slag, not the degradation of the pot. Because the crucible resists chemical erosion, researchers can be confident that observed changes are due to the experimental variables, not a failing vessel.

Understanding the Trade-offs

While high-density MgO is the superior choice for these parameters, understanding its limitations is vital for experimental success.

Purity vs. Performance

The 99.8% purity level is not a luxury; it is a requirement. Using lower-purity MgO would likely introduce impurities that lower the crucible's melting point or reactivity threshold, leading to failure at 1600°C.

The Risk of Erosion

Despite its resistance, MgO is not invincible. If the slag composition becomes excessively aggressive or the temperature exceeds the rated limit, chemical erosion can still occur, emphasizing the need to operate strictly within the material's thermal and chemical specifications.

Making the Right Choice for Your Goal

To ensure your liquid steelmaking slag experiments yield valid results, consider the following recommendations:

- If your primary focus is Data Accuracy: Ensure your crucible certification confirms 99.8% purity to eliminate the risk of leaching contaminants into your melt.

- If your primary focus is Equipment Longevity: Prioritize high-density manufacturing specifications to maximize resistance against penetration by iron and manganese oxides.

The success of high-temperature slag reduction relies on treating the crucible not just as a cup, but as a precision chemical component that must remain invisible to the reaction.

Summary Table:

| Feature | Specification | Role in Slag Reduction Experiments |

|---|---|---|

| Material Purity | 99.8% MgO | Prevents chemical leaching and maintains slag composition integrity. |

| Density | High Density | Low porosity prevents mechanical penetration and slag erosion. |

| Thermal Limit | Up to 1600°C+ | Maintains structural rigidity and refractoriness under extreme heat. |

| Chemical Resistance | High | Resists aggressive iron and manganese oxides common in liquid slag. |

Maximize Your Experimental Accuracy with KINTEK

Don't let crucible contamination compromise your research. KINTEK provides high-purity MgO crucibles designed specifically for the rigorous demands of steelmaking slag analysis. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces to meet your unique thermal processing needs.

Ready to elevate your lab's precision? Contact us today to consult with our experts on the perfect high-temperature solution for your application.

Visual Guide

References

- M. A. Levchenko, Olena Volkova. Reduction of Liquid Steelmaking Slag Using Hydrogen Gas as a Reductant. DOI: 10.3390/met15090984

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What role does an alumina crucible play during the gas nitriding process for stainless steel? Ensure Surface Purity

- Why is ASTM A36 steel plate used for heat treatment furnace frameworks? Reliable Strength & Cost-Efficiency

- How do high-precision mass flow controllers assist in the formation of superlattice structures? Mastery of 2D CVD

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- Why is a sealing lid necessary for the clay-graphite crucible? Key to Successful Fe3O4/C Composite Synthesis

- How does a vacuum pump facilitate the pre-treatment of modified multi-walled carbon nanotubes? Optimize Surface Activation

- What are the key advantages of using quartz tubes in high-temperature applications? Achieve Unmatched Thermal Stability and Purity

- What is the role of an infrared pyrometer in wood carbonization? Optimize Your High-Temp Thermal Control