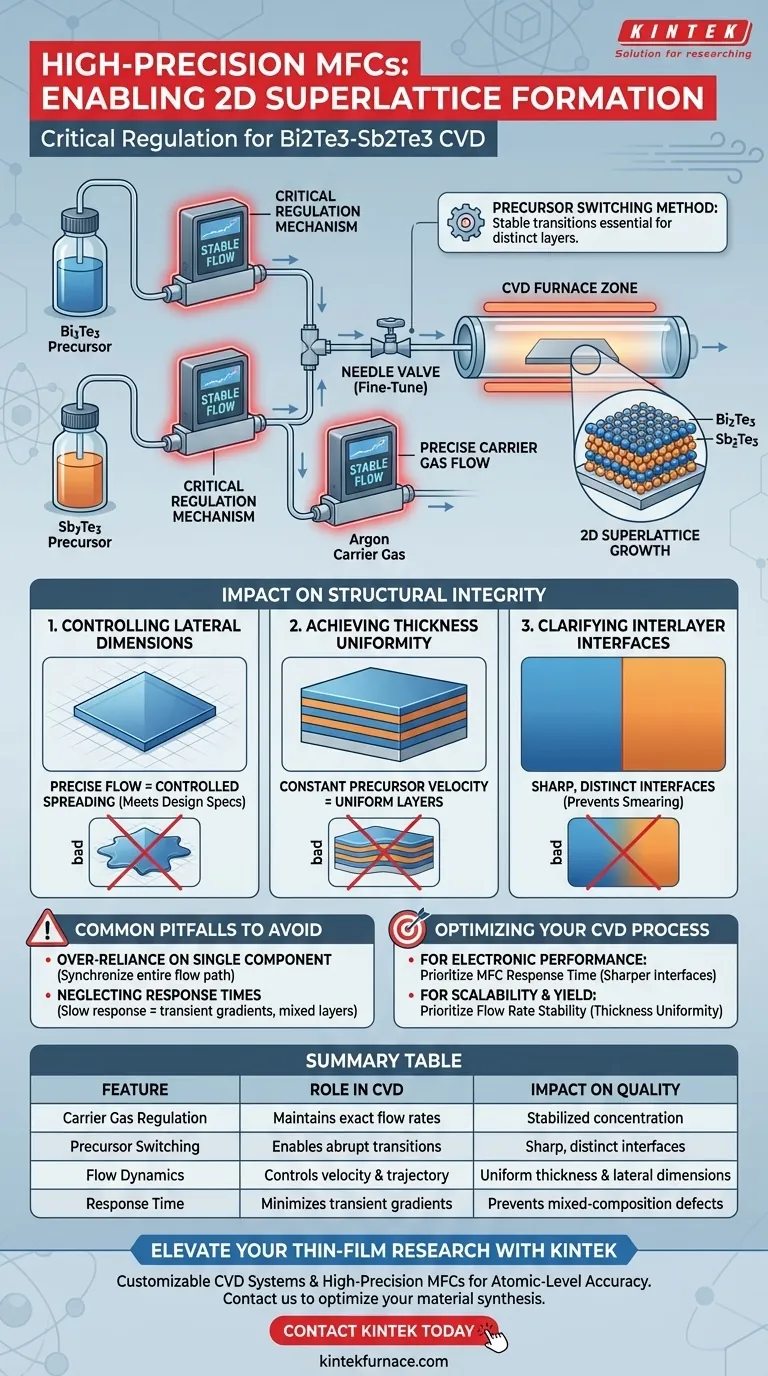

High-precision mass flow controllers (MFCs) serve as the critical regulation mechanism for carrier gas flow rates during the Chemical Vapor Deposition (CVD) of 2D Bi2Te3-Sb2Te3. By working in tandem with needle valves, these controllers ensure that precursor molecules are delivered to the substrate surface with stabilized concentrations and velocities, which is essential for successful layer formation.

The rigorous control provided by MFCs allows for the precise execution of the "precursor switching method." This stability is the deciding factor in achieving uniform thickness, controlled lateral dimensions, and sharp, distinct interfaces between superlattice layers.

The Role of Flow Control in Precursor Switching

Regulating Carrier Gases

In CVD processes, the carrier gas (typically argon) acts as the transport vehicle for precursor materials.

MFCs are responsible for maintaining the exact flow rate of this gas. Any fluctuation here directly alters the amount of material reaching the substrate.

Synergy with Needle Valves

MFCs do not operate in isolation; they function alongside needle valves to fine-tune the delivery system.

While the MFC sets the bulk flow rate, the combined system ensures that the precursor molecules maintain a consistent trajectory and density as they approach the deposition zone.

Stabilizing Precursor Delivery

The formation of a superlattice requires the alternating deposition of different materials (Bi2Te3 and Sb2Te3).

MFCs enable the precursor switching method by ensuring that when the system switches from one source to another, the transition is stable. This prevents surges or drops in concentration that could disrupt the growth lattice.

Impact on Superlattice Structural Integrity

Controlling Lateral Dimensions

The size and shape of the 2D crystals across the substrate surface are dictated by the flow dynamics.

Precise flow control prevents uncontrolled spreading, ensuring the lateral dimensions of the growing crystal meet design specifications.

Achieving Thickness Uniformity

In 2D materials, a variance of even a single atomic layer is significant.

By maintaining constant precursor velocity, MFCs ensure that the deposition rate is uniform across the entire substrate, resulting in consistent layer thickness.

Clarifying Interlayer Interfaces

The performance of a superlattice depends heavily on the boundary where two different materials meet.

High-precision control ensures that the switch between layers is abrupt rather than gradual. This results in clear, sharp interlayer interfaces, preventing the "smearing" of materials that degrades electronic properties.

Common Pitfalls to Avoid

Over-Reliance on a Single Component

While MFCs are vital, they are part of a broader ecosystem including needle valves and pressure regulators.

Precision in the MFC alone is insufficient if downstream valves are poorly calibrated or if the precursor source temperature fluctuates. The entire flow path must be synchronized.

Neglecting Response Times

In the precursor switching method, the speed at which an MFC stabilizes after a setpoint change is critical.

If the controller has a slow response time, it creates a transient gradient of concentration. This leads to mixed-composition layers rather than the distinct, sharp superlattice structures required.

Optimizing Your CVD Process

To maximize the quality of your 2D Bi2Te3-Sb2Te3 superlattices, focus your equipment calibration based on your specific structural goals.

- If your primary focus is Electronic Performance: Prioritize MFC response time to ensure the sharpest possible interlayer interfaces, reducing electron scattering at boundaries.

- If your primary focus is Scalability and Yield: Prioritize the stability of the flow rate over long durations to ensure thickness uniformity across larger substrates.

True precision in CVD is not just about moving gas; it is about guaranteeing the stability of the environment where atomic assembly takes place.

Summary Table:

| Feature | Role in CVD Superlattice Formation | Impact on Material Quality |

|---|---|---|

| Carrier Gas Regulation | Maintains exact argon flow rates via MFCs | Ensures stabilized precursor concentration |

| Precursor Switching | Enables abrupt transitions between materials | Creates sharp, distinct interlayer interfaces |

| Flow Dynamics | Controls precursor velocity and trajectory | Guarantees uniform thickness and lateral dimensions |

| Response Time | Minimizes transient concentration gradients | Prevents mixed-composition layer defects |

Elevate Your Thin-Film Research with KINTEK

Precise control is the difference between a flawed film and a perfect superlattice. KINTEK provides industry-leading CVD systems, including Muffle, Tube, Rotary, and Vacuum furnaces, all of which can be customized with high-precision MFCs to meet your specific R&D requirements.

Our expert manufacturing and R&D support ensure your laboratory is equipped to achieve atomic-level accuracy in every deposition. Contact KINTEK today to discuss your custom furnace needs and let us help you optimize your material synthesis process.

Visual Guide

References

- Han Wang, Wen Lei. Superlattice Engineering on 2D Bi<sub>2</sub>Te<sub>3</sub>‐Sb<sub>2</sub>Te<sub>3</sub> Chalcogenides. DOI: 10.1002/advs.202503492

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a laboratory blast drying oven facilitate BCZT gel drying? Precision Solutions for High-Quality Xerogels

- Why are YSZ milling balls selected for mixing Mn2AlB2 precursor powders? Ensure High-Purity MAB Phase Synthesis

- Why are high-temperature ceramic crucibles used for chalcopyrite? Ensure Purity in Ore Thermal Treatment

- Why is a high-purity alumina corundum crucible preferred for melting? Achieve High-Precision Research Integrity

- How does a laboratory high-temperature oven facilitate the destabilization of lignin? Optimize Biomass Pretreatment

- How do vacuum filtration systems operate in industrial sludge dehydration? Achieve Efficient Liquid-Solid Separation

- Why is radiation correction necessary for K-type thermocouple readings? Ensure Accurate High-Temp Combustion Data

- What are the placement requirements for high-precision standard thermocouples? Master Sensor Calibration Accuracy