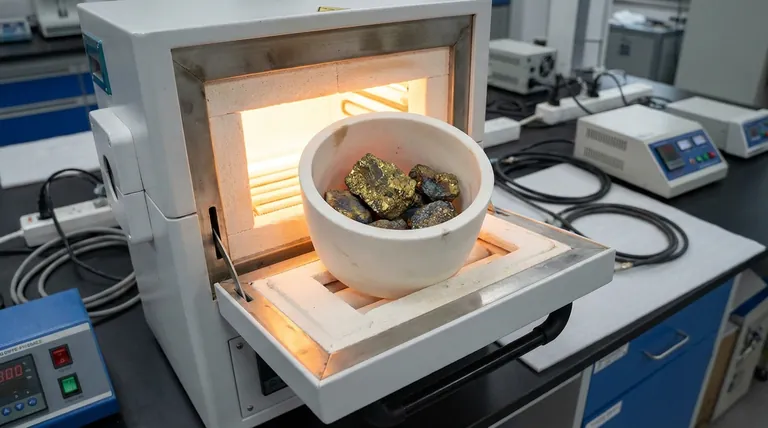

High-temperature ceramic crucibles are chosen primarily for their ability to maintain structural integrity and chemical neutrality under extreme thermal conditions. Specifically, they withstand pretreatment temperatures of 600°C or higher without deforming, ensuring the chalcopyrite ore remains pure and chemically unaltered by the container during processing.

The utility of ceramic crucibles lies in their "invisible" presence during experimentation; they provide stable physical support and uniform heat transfer while ensuring that all measured changes are intrinsic to the ore, not the container.

The Critical Role of Thermal Stability

Withstanding Extreme Heat

The thermal treatment of chalcopyrite often requires temperatures exceeding 600°C.

Ceramic crucibles are selected because they resist deformation at these high temperatures. Unlike metal or glass containers that might soften or warp, high-grade ceramics maintain their rigid shape, providing a reliable vessel for the ore throughout the heating cycle.

Ensuring Uniform Heat Transfer

Consistent results rely on how evenly heat is applied to the sample.

Ceramic crucibles provide stable physical support that facilitates uniform heat transfer. This ensures that the entire sample experiences the same thermal conditions, preventing localized hot spots that could skew experimental results or processing efficiency.

Preserving Chemical Integrity

Preventing Chemical Contamination

The most critical requirement for sample containers is chemical inertness.

Ceramic crucibles do not react with chalcopyrite ore, even at elevated temperatures. This isolation prevents the container material from leaching into the sample or reacting with the mineral, guaranteeing that the final product remains pure.

Ensuring Data Accuracy in Analysis

For analytical techniques like Thermogravimetric-Differential Scanning Calorimetry (TG-DSC), the container must not interfere with the readings.

Because ceramics do not react with the sample or its pyrolysis products, any mass changes or heat flows detected are solely attributable to the sintering material. This eliminates "noise" in the data caused by container interference.

Facilitating Mechanical Processing

Inducing Micro-Cracks

A primary goal of thermally treating chalcopyrite is to induce thermal stress.

Heating the ore to temperatures between 300°C and 600°C creates micro-cracks within the mineral structure. The ceramic crucible withstands the heat required to weaken the ore's mechanical strength.

Improving Grinding Efficiency

The structural weakening facilitated by the crucible's heat resistance has downstream benefits.

By allowing the ore to be heated sufficiently to fracture internally, the energy required for subsequent grinding and fragmentation is significantly reduced.

Understanding Operational Considerations

Material Selection Matters

While "ceramic" is the general category, specific materials like high-purity alumina are often preferred.

Alumina offers exceptional stability, capable of withstanding temperatures exceeding 1450°C. However, operators must ensure they select the correct grade of ceramic for their specific temperature range to avoid unexpected failures.

Thermal Shock Risks

While ceramics resist high heat, they can be sensitive to rapid temperature changes.

Extreme care must be taken during the cooling phase. Rapid cooling can cause the crucible itself to crack due to thermal shock, potentially ruining the sample or the equipment.

Making the Right Choice for Your Goal

To maximize the effectiveness of your thermal treatment, align your equipment choice with your specific objective:

- If your primary focus is Analytical Precision: Prioritize high-purity alumina crucibles to ensure zero interference with TG-DSC curves and mass change data.

- If your primary focus is Process Efficiency: Utilize standard high-temperature ceramic crucibles that can consistently hold stable at 600°C to induce the micro-cracking necessary for easier grinding.

Select the crucible that offers the highest thermal headroom above your target temperature to ensure safety and data integrity.

Summary Table:

| Feature | Benefit for Chalcopyrite Treatment |

|---|---|

| Thermal Stability | Resists deformation at 600°C+ for consistent sample containment |

| Chemical Inertness | Prevents sample contamination and ensures data accuracy in TG-DSC |

| Heat Transfer | Facilitates uniform heating to induce micro-cracks for easier grinding |

| Structural Integrity | Withstands high thermal stress required to weaken mineral bonds |

Elevate Your Mineral Processing Precision with KINTEK

Don't let container contamination compromise your research or production efficiency. KINTEK provides high-performance ceramic crucibles and advanced thermal solutions designed to withstand the rigors of chalcopyrite ore treatment.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all customizable to your unique thermal processing needs.

Ready to optimize your thermal treatment workflows? Contact our technical experts today to find the perfect furnace and crucible combination for your laboratory.

References

- Kaveh Asgari, Qingqing Huang. Investigating the Effect of Thermal Pretreatment on Chalcopyrite Grinding for Comminution Energy Reduction. DOI: 10.3390/en18112989

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of a water-cooled condenser in a thermal vacuum mercury removal apparatus? Key for Safe Recovery

- What function does a vacuum pump perform in simulated vacuum refining? Optimize Aluminum Alloy Purity & Defect Analysis

- What are the functions of high-purity, high-strength graphite molds in SPS? Optimize Al2O3-TiC Ceramic Sintering

- Why are laboratory precision stirrers and heating devices essential for synthesizing magnetic precursor solutions?

- Why are high-purity alumina crucibles required for high-temperature melting studies of sintering ores? Expert Insights

- Why is selecting the right laboratory furnace important for ceramic sintering? Ensure Precise Control for Superior Ceramic Properties

- What are the functions of a boron nitride (BN) crucible and internal packing powder? Optimize Si3N4 Sintering Now

- Why is a quartz tube utilized as the primary reaction vessel? Optimize Microwave-Assisted Metal Recovery Efficiency