Quartz tubes are selected as the primary reaction vessel because they provide a unique combination of electromagnetic transparency and physical durability. They allow microwave energy to pass through to the sample without absorbing heat, while simultaneously acting as a rigorous barrier to maintain vacuum or inert gas environments.

By combining low dielectric loss with high infrared transparency, the quartz tube enables precise, real-time temperature monitoring and efficient heating while isolating reactive metals from atmospheric oxygen.

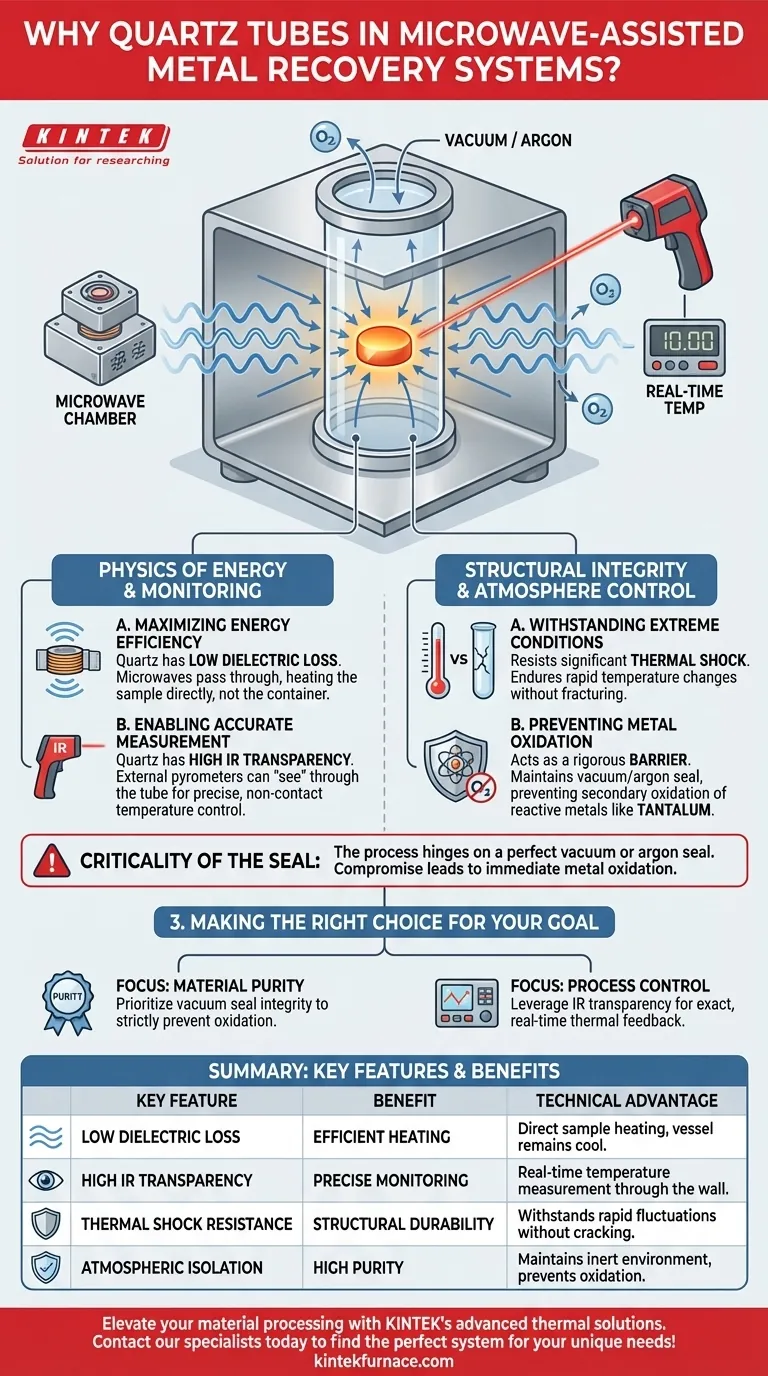

The Physics of Energy and Monitoring

Maximizing Energy Efficiency

The primary requirement for microwave heating is that the vessel must not absorb the energy intended for the metal. Quartz possesses low dielectric loss.

This means microwave radiation passes through the tube wall to heat the internal sample directly, rather than heating the container itself.

Enabling Accurate Measurement

Precise temperature control is critical in metal recovery. Quartz features high infrared (IR) transparency.

Because the material is transparent to IR wavelengths, external infrared pyrometers can "see" through the tube walls. This allows operators to monitor the real-time temperature of the sample inside without physical contact.

Structural Integrity and Atmosphere Control

Withstanding Extreme Conditions

Microwave heating often involves rapid changes in temperature. Quartz is chosen for its ability to withstand significant thermal shock.

It can endure the stress of high-temperature processing without fracturing, ensuring the physical safety of the recovery setup.

Preventing Metal Oxidation

Many metals targeted for recovery, such as tantalum, are highly reactive to oxygen at high temperatures. The quartz tube acts as a vacuum seal and atmospheric isolation barrier.

It maintains the necessary argon atmosphere or vacuum environment effectively. This prevents secondary oxidation, ensuring the purity of the recovered metal.

Operational Constraints

The Criticality of the Seal

While quartz is robust, its primary function in this context is atmospheric isolation. The effectiveness of the entire process hinges on the tube's ability to maintain a perfect vacuum or argon seal.

If the structural integrity is compromised even slightly, oxygen infiltration will lead to immediate oxidation of the metal sample.

Making the Right Choice for Your Goal

To optimize your microwave-assisted recovery process, consider which property of the quartz vessel is most critical to your specific objective.

- If your primary focus is Material Purity: Prioritize the integrity of the quartz tube's vacuum seal to strictly prevent secondary oxidation of reactive metals like tantalum.

- If your primary focus is Process Control: Leverage the tube's infrared transparency to align external pyrometers for exact, real-time thermal feedback.

The quartz tube is not just a container; it is an active component that bridges the gap between efficient energy transfer and strict environmental control.

Summary Table:

| Key Feature | Benefit in Metal Recovery | Technical Advantage |

|---|---|---|

| Low Dielectric Loss | Efficient Heating | Microwaves pass through directly to the sample without heating the vessel. |

| High IR Transparency | Precise Monitoring | Allows external pyrometers to measure real-time temperature through the tube wall. |

| Thermal Shock Resistance | Structural Durability | Withstands rapid temperature fluctuations without fracturing or cracking. |

| Atmospheric Isolation | High Purity | Maintains vacuum or argon seals to prevent oxidation of reactive metals like tantalum. |

Elevate your material processing with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, we provide high-performance Tube, Muffle, and Vacuum systems tailored for microwave-assisted recovery and specialized lab applications. Whether you need precise temperature control or customizable furnace configurations, KINTEK delivers the reliability your research demands. Contact our specialists today to find the perfect system for your unique needs!

Visual Guide

References

- Ansan Pokharel, Terence Musho. Microwave-assisted recycling of tantalum and manganese from end-of-life tantalum capacitors. DOI: 10.1038/s41598-025-96574-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is high-purity tantalum foil used when melting Ce2(Fe, Co)17 alloy? Protect Your Rare-Earth Materials

- How does the use of laboratory grinding equipment benefit NRBBO:Eu2+ phosphors? Optimize Your Material Synthesis

- Why is the use of high-purity alumina crucibles essential for the synthesis of Ni3In2Se2? | Precision Material Purity

- What role do quartz tubes play in semiconductor manufacturing? Essential for Purity and High-Temp Processes

- What is the function of a honeycomb-shaped firing tray? Master Thermal Equilibrium in Ceramic Sintering

- What is the significance of using high-purity quartz tubes in MoS2 growth? Ensure High-Purity Crystal Synthesis

- What role do high-purity graphite crucibles play in Boron Carbide sintering? Optimize Ceramic Purity and Density

- What are the key characteristics of the alumina furnace tube? Essential for High-Temp Lab Success