In semiconductor manufacturing, quartz tubes are the invisible guardians of purity and precision. They function as ultra-pure, high-temperature process chambers for the most critical fabrication steps. These tubes create a controlled, contaminant-free environment where silicon wafers are subjected to extreme heat for processes like thermal oxidation, thin film deposition, and chemical etching.

The core challenge in semiconductor fabrication is managing extreme heat and preventing microscopic contamination. Quartz is the default material for process tubes because it uniquely combines exceptional chemical purity with the ability to withstand extreme temperatures without warping or reacting, safeguarding the integrity of the integrated circuits being built.

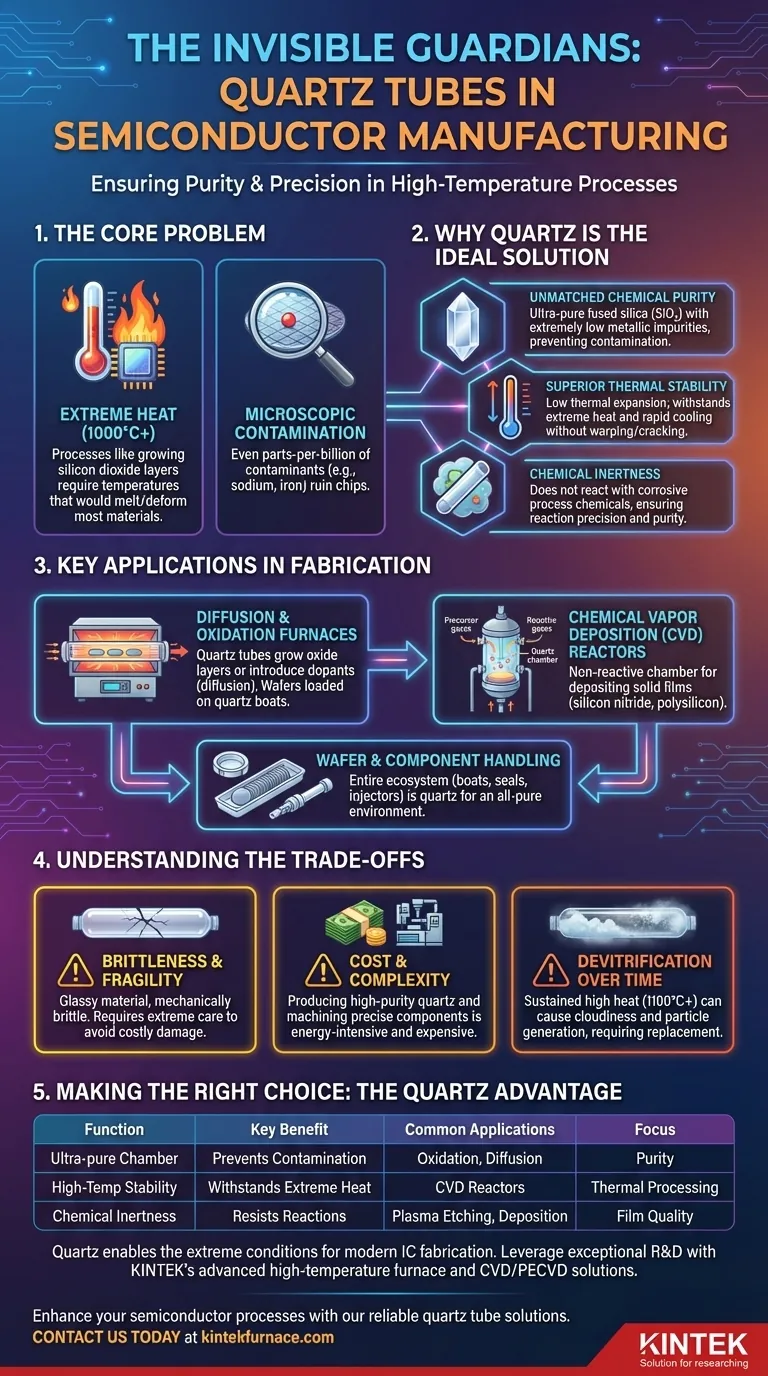

The Core Problem: Contamination and Extreme Heat

Semiconductor manufacturing pushes materials to their absolute limits. The two fundamental challenges that quartz directly solves are the need for an ultra-clean environment and the ability to endure incredibly high temperatures.

The Need for Absolute Purity

In microchip fabrication, a single unwanted atom can be a critical defect. Contaminants like sodium or iron, even in parts-per-billion concentrations, can migrate into the silicon wafer and alter its electrical properties, rendering the chip useless.

Therefore, the chamber where wafers are processed cannot introduce any impurities.

The Challenge of High-Temperature Processing

Many critical steps, such as growing a silicon dioxide insulating layer, require temperatures well over 1000°C (1832°F).

At these temperatures, most materials would melt, deform, or react with the process gases, releasing contaminants and destroying the delicate circuits on the wafer.

Why Quartz is the Ideal Solution

Quartz, which is a high-purity form of fused silica (SiO₂), possesses a combination of properties that make it almost perfectly suited for this demanding role.

Unmatched Chemical Purity

High-purity quartz is one of the purest materials that can be manufactured at scale. It contains extremely low levels of metallic impurities, preventing them from leaching out and contaminating the silicon wafers during high-temperature steps.

Superior Thermal Stability

Quartz has a very low coefficient of thermal expansion. This means it can be heated to extreme temperatures and cooled down without significant expansion or contraction, which prevents it from warping, cracking, or breaking under thermal stress.

Chemical Inertness

Quartz does not react with the highly reactive and corrosive chemicals used in processes like Chemical Vapor Deposition (CVD) or plasma etching. This ensures that the tube itself doesn't interfere with the precise chemical reactions needed to deposit or remove films on the wafer.

Key Applications in the Fabrication Process

Quartz components are used wherever wafers are exposed to high heat and reactive chemicals. The tube is just the most visible part of a larger quartz ecosystem.

Diffusion and Oxidation Furnaces

The quartz tube forms the main body of a horizontal or vertical furnace. Wafers are loaded into the tube on quartz boats (or carriers) to ensure an all-quartz environment.

Hot gases are then passed through the tube to either grow a uniform layer of silicon dioxide (oxidation) or to introduce dopants that modify the silicon's electrical conductivity (diffusion).

Chemical Vapor Deposition (CVD) Reactors

In CVD, the quartz tube acts as the reaction chamber. Precursor gases are introduced, which react at high temperatures and deposit a solid thin film—such as silicon nitride or polysilicon—onto the surface of the wafers.

The non-reactive nature of the quartz ensures the purity of the deposited film.

Wafer and Component Handling

Beyond the main process tube, other components inside the furnace are also made of quartz. This includes the wafer boats that hold the wafers, end caps that seal the tube, and gas injectors that deliver process chemicals.

Understanding the Trade-offs

While quartz is the industry standard, it is not without limitations. Understanding these trade-offs is key to managing semiconductor processes effectively.

Brittleness and Fragility

Despite its strength against thermal shock, quartz is a glass and is mechanically brittle. It must be handled with extreme care, as a physical impact can cause it to crack or shatter, leading to costly downtime.

Cost and Manufacturing Complexity

Producing quartz with the near-perfect purity required for semiconductor fabrication is an expensive and energy-intensive process. Machining the material into large, precise tubes and complex components further adds to the cost.

Devitrification Over Time

At sustained temperatures above 1100°C, quartz can begin to lose its glassy (amorphous) structure and revert to a crystalline state, a process called devitrification. This makes the material cloudy, more brittle, and prone to generating particles, requiring its eventual replacement.

Making the Right Choice for Your Goal

The function of the quartz tube is directly tied to the specific process goal. Its role is always to protect the integrity of the wafer.

- If your primary focus is thermal processing (oxidation/diffusion): The quartz tube's role is to provide a stable, inert, and ultra-clean thermal environment, ensuring uniform layer growth across every wafer.

- If your primary focus is thin film deposition (CVD): The quartz tube serves as a non-reactive chamber, guaranteeing the purity of the precursor gases and the quality of the resulting deposited film.

- If your primary focus is preventing contamination: The intrinsic high purity of the quartz is its single most critical feature, acting as the first and best line of defense against impurities that would destroy device performance.

Ultimately, using quartz for process chambers is a foundational decision that enables the extreme conditions required to fabricate modern integrated circuits.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Ultra-pure process chamber | Prevents contamination of silicon wafers | Thermal oxidation, diffusion furnaces |

| High-temperature stability | Withstands extreme heat without warping | Chemical Vapor Deposition (CVD) reactors |

| Chemical inertness | Resists reactions with process gases | Plasma etching, thin film deposition |

| Fragility and cost trade-offs | Requires careful handling and high purity | All high-heat semiconductor processes |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Enhance your semiconductor processes with our reliable quartz tube solutions—contact us today to learn how we can support your fabrication goals!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment