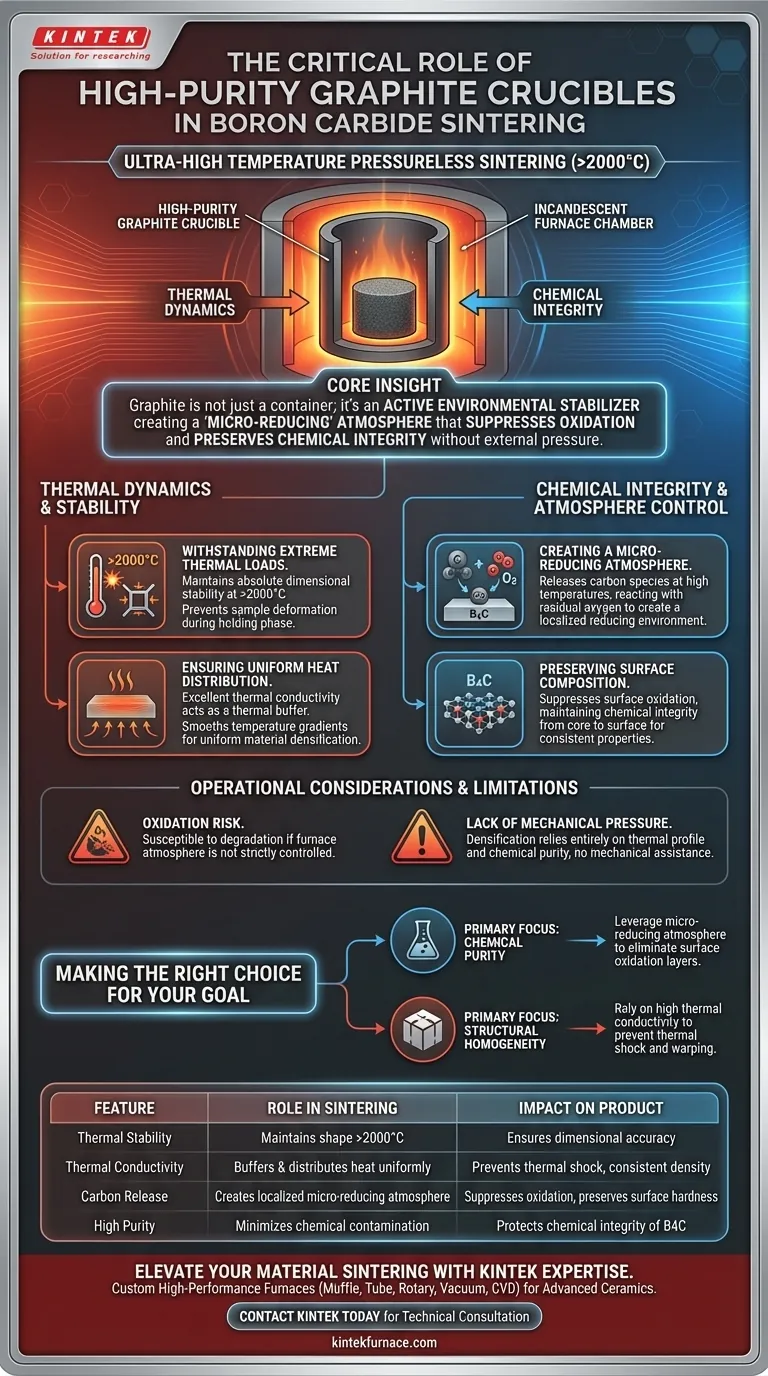

High-purity graphite crucibles function as the critical environmental stabilizer for Boron Carbide ceramics undergoing ultra-high temperature pressureless sintering. They provide a container capable of maintaining absolute dimensional stability at temperatures exceeding 2000°C while ensuring the thermal uniformity required for consistent material densification.

Core Insight: The value of a high-purity graphite crucible extends beyond mere containment; it actively creates a "micro-reducing" atmosphere that suppresses oxidation, preserving the chemical integrity of the Boron Carbide surface without the need for external pressure application.

Thermal Dynamics and Stability

Withstanding Extreme Thermal Loads

Pressureless sintering of Boron Carbide requires temperatures that often exceed 2000°C.

At these extremes, most standard containment materials soften, react, or deform. High-purity graphite maintains rigid dimensional stability, ensuring the ceramic sample is not mechanically compromised during the holding phase of the sintering cycle.

Ensuring Uniform Heat Distribution

Achieving a dense ceramic requires that the entire sample reaches the target temperature simultaneously.

Graphite possesses excellent thermal conductivity. This property allows the crucible to act as a thermal buffer, smoothing out temperature gradients from the furnace and ensuring the Boron Carbide sample experiences uniform heat during the ramp-up.

Chemical Integrity and Atmosphere Control

Creating a Micro-Reducing Atmosphere

One of the most sophisticated roles of the graphite crucible is its chemical interaction with the immediate atmosphere.

At high temperatures, the graphite releases carbon species that react with residual oxygen within the crucible. This creates a localized micro-reducing environment surrounding the sample.

Preserving Surface Composition

Boron Carbide is susceptible to oxidation, which can degrade its hardness and surface properties.

The micro-reducing atmosphere suppresses micro-oxidation on the sample's surface. This is critical for maintaining the chemical composition integrity of the final ceramic product, ensuring that the material properties remain consistent from the core to the surface.

Operational Considerations and Limitations

While high-purity graphite is essential for this process, it is not without constraints.

Oxidation Risk of the Crucible: Graphite itself creates a reducing atmosphere, but it is highly susceptible to oxidation if the external furnace atmosphere is not strictly controlled. If the furnace allows too much oxygen ingress, the crucible will degrade rapidly.

Lack of Mechanical Pressure: Unlike hot pressing or Spark Plasma Sintering (SPS) where graphite molds transmit mechanical force to aid densification, a crucible in pressureless sintering offers no mechanical assistance. Densification relies entirely on the thermal profile and chemical purity provided by the crucible.

Making the Right Choice for Your Goal

To maximize the effectiveness of high-purity graphite crucibles in your sintering protocols, align your usage with your specific material objectives.

- If your primary focus is Chemical Purity: Leverage the crucible's naturally occurring micro-reducing atmosphere to eliminate surface oxidation layers without introducing foreign reducing agents.

- If your primary focus is Structural Homogeneity: Rely on the high thermal conductivity of the graphite to prevent thermal shock and warping during rapid heating ramp-ups.

The graphite crucible is not just a vessel; it is an active participant in the thermal and chemical stabilization of high-performance ceramics.

Summary Table:

| Feature | Role in Boron Carbide Sintering | Impact on Final Product |

|---|---|---|

| Thermal Stability | Maintains shape at >2000°C without deformation | Ensures dimensional accuracy of ceramic parts |

| Thermal Conductivity | Buffers and distributes heat uniformly | Prevents thermal shock and ensures consistent density |

| Carbon Release | Creates a localized micro-reducing atmosphere | Suppresses oxidation and preserves surface hardness |

| High Purity | Minimizes chemical contamination | Protects the chemical integrity of the B4C material |

Elevate Your Material Sintering with KINTEK Expertise

Precision in ultra-high temperature sintering requires more than just high-purity graphite; it requires the right thermal environment. KINTEK provides industry-leading R&D and manufacturing of high-performance lab equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Our furnaces are fully customizable to meet the unique thermal dynamics of Boron Carbide and other advanced ceramics. Whether you need precise atmosphere control or extreme temperature stability, our expert team is ready to design a solution tailored to your lab's specific needs.

Ready to achieve superior material densification? Contact KINTEK today to consult with our technical specialists!

Visual Guide

References

- J. Q. Wang, Li Hou. Mechanical and Drying Shrinkage Performance Study of Ultra-High-Performance Concrete Prepared from Titanium Slag under Different Curing Conditions. DOI: 10.3390/ma17174201

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the function of a graphite plate in microwave cladding? Ensure Purity & Thermal Uniformity for HEA Synthesis

- What roles does a high-purity graphite mold serve during the Spark Plasma Sintering (SPS) of TiC-SiC composites?

- What is the purpose of using an insulating layer in CCCM thermal conductivity tests? Ensuring 1D Heat Flow Accuracy

- What factors affect the light transmittance of alumina tubes? Balance Clarity and Durability for Your Lab

- What role does a high-precision constant temperature drying oven play in battery electrode preparation? Master Battery Performance

- Why is a covered porcelain crucible used for activated carbon calcination? Secure Your High-Quality Carbon Yield

- What advantages does a vacuum drying oven offer for BiFeO3 electrode sheets? Optimize Your Battery Research

- How does a high-pressure reaction kettle facilitate 3D core-shell formation? Mastering Hydrothermal Catalyst Synthesis