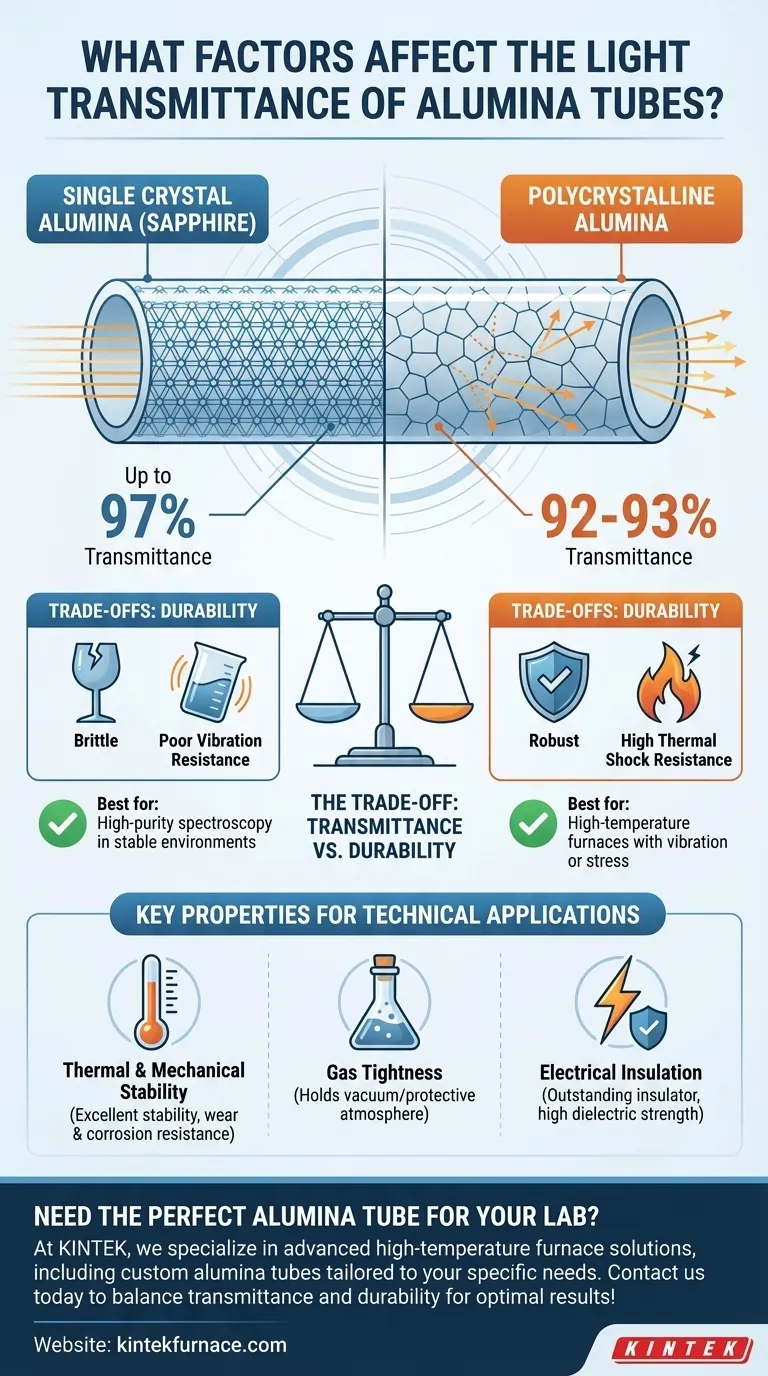

The single most important factor affecting the light transmittance of an alumina tube is its crystalline structure. Specifically, the choice between a polycrystalline and a single crystal (sapphire) structure dictates the material's optical clarity. While single crystal tubes offer higher transmittance, this performance comes with significant trade-offs in durability.

Choosing the right alumina tube is not about maximizing light transmittance alone. It requires balancing the need for optical clarity against the mechanical and thermal demands of your specific application.

The Role of Crystalline Structure

The arrangement of atoms within the alumina material directly impacts how light travels through it. This fundamental difference gives rise to two distinct types of transparent alumina tubes.

Single Crystal Alumina (Sapphire)

A single crystal alumina tube, also known as a sapphire tube, is grown as one continuous, uniform crystal lattice. This lack of internal grain boundaries minimizes light scattering.

As a result, single crystal tubes achieve the highest possible light transmittance, often reaching up to 97%. This makes them optically superior for applications requiring maximum clarity.

Polycrystalline Alumina

Polycrystalline alumina is formed from many small, individual alumina grains that are sintered together. The interfaces where these grains meet are called grain boundaries.

These boundaries act as scattering centers, deflecting a small portion of the light that passes through. This internal scattering reduces the overall light transmittance to a still-impressive 92-93%.

Understanding the Trade-offs: Transmittance vs. Durability

The superior optical performance of single crystal alumina comes at a cost. The decision between the two types almost always hinges on the mechanical environment where the tube will be used.

The Fragility of Single Crystal Tubes

The uniform lattice of a single crystal, while optically perfect, makes the material more brittle.

These tubes have poor vibration resistance and are more susceptible to fracture from mechanical shock or stress. They are best suited for controlled, stable environments.

The Robustness of Polycrystalline Tubes

Polycrystalline alumina offers significantly better all-around durability. Its structure provides superior thermal shock resistance, wear resistance, and general mechanical strength.

While you sacrifice a few percentage points of light transmittance, you gain a component that can reliably withstand the rigors of high-temperature furnaces and environments with vibration or potential for mechanical stress.

Key Properties for Technical Applications

Beyond optical clarity, alumina tubes are chosen for a combination of other elite properties that make them ideal for extreme environments.

Thermal and Mechanical Stability

Alumina exhibits excellent stability at high temperatures, low thermal expansion, and high compressive strength. It is also highly resistant to wear and corrosion.

Gas Tightness

Both tube types are gas tight, meaning they can hold a vacuum or maintain a protective, controlled atmosphere within a furnace, which is critical for many high-temperature processes.

Electrical Insulation

Alumina is an outstanding electrical insulator, with a high dielectric strength. This is crucial for applications where the tube must isolate electrical components within a high-temperature zone.

Making the Right Choice for Your Goal

To select the correct material, you must prioritize your primary requirement.

- If your primary focus is maximum optical clarity: Choose a single crystal (sapphire) tube for applications like high-purity spectroscopy, but ensure the system is protected from vibration and mechanical shock.

- If your primary focus is durability in a harsh environment: Choose a polycrystalline alumina tube for general use in high-temperature furnaces, where its superior resistance to thermal shock and vibration is paramount.

Ultimately, your decision is a direct trade-off between ideal optical performance and practical mechanical resilience.

Summary Table:

| Factor | Single Crystal (Sapphire) | Polycrystalline Alumina |

|---|---|---|

| Light Transmittance | Up to 97% | 92-93% |

| Durability | Brittle, poor vibration resistance | Robust, high thermal shock resistance |

| Best For | High-purity spectroscopy in stable environments | High-temperature furnaces with vibration or stress |

Need the perfect alumina tube for your lab? At KINTEK, we specialize in advanced high-temperature furnace solutions, including custom alumina tubes tailored to your specific needs. Whether you require the superior optical clarity of single crystal sapphire or the rugged durability of polycrystalline alumina, our expert R&D and in-house manufacturing ensure precise performance. Let us help you balance transmittance and durability for optimal results—contact us today to discuss your application!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs