The primary advantage of using a vacuum drying oven for BiFeO3 electrode sheets is its ability to operate in a dynamic vacuum environment at a relatively low temperature of 60 °C.

This environment accelerates the evaporation of solvents and moisture while simultaneously preventing the oxidation or degradation of the active materials. By avoiding high-temperature air exposure, this method ensures the chemical composition of the BiFeO3 remains stable throughout the drying process.

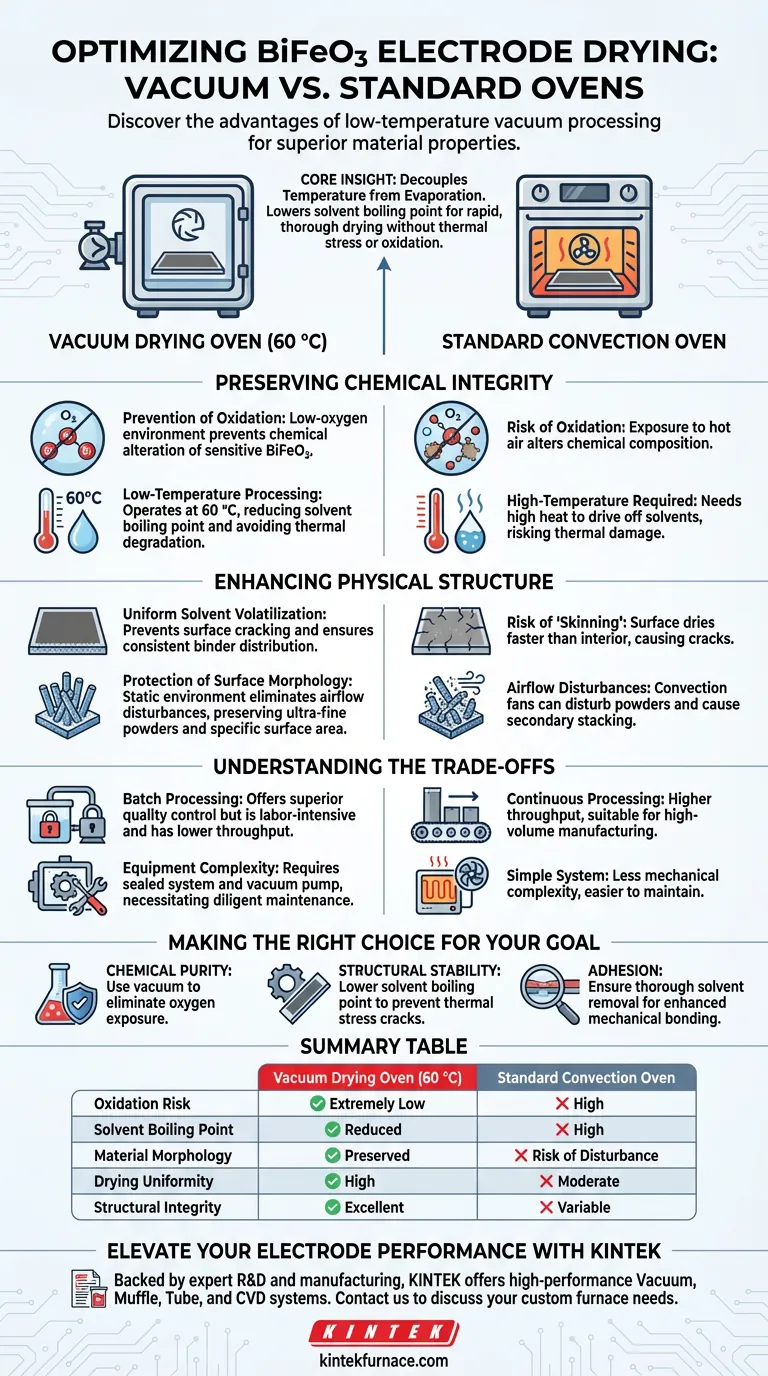

Core Insight: Vacuum drying decouples temperature from evaporation speed. By lowering the pressure, you lower the boiling point of solvents, allowing for rapid, thorough drying without the thermal stress or oxidative damage associated with standard convection ovens.

Preserving Chemical Integrity

Prevention of Oxidation

Standard ovens typically rely on heated air circulation to dry materials. For sensitive materials like BiFeO3, this exposure to oxygen at elevated temperatures can alter the chemical composition.

A vacuum oven removes the air from the chamber. This creates a low-oxygen environment that effectively prevents oxidation reactions, preserving the purity and stability of the active electrode material.

Low-Temperature Processing

In a standard oven, high temperatures are often required to drive off solvents quickly.

A vacuum oven reduces the environmental pressure, which significantly lowers the boiling point of solvents and moisture. This allows BiFeO3 to be dried effectively at just 60 °C, avoiding the thermal degradation that can occur with higher heat settings.

Enhancing Physical Structure

Uniform Solvent Volatilization

Standard drying can sometimes cause the surface of a slurry to dry faster than the interior, leading to "skinning" or cracking.

Vacuum drying promotes more uniform volatilization of solvents (such as NMP or ethanol) from within the electrode material. This prevents surface cracking and ensures a more consistent distribution of the binder between the active material and the current collector.

Protection of Surface Morphology

For electrode materials involving nanostructures or porous composites, airflow is a critical factor.

Standard ovens utilize convection fans that can disturb ultra-fine powders or cause secondary stacking of nanosheets. The static environment of a vacuum oven eliminates these airflow disturbances, preserving the original microscopic morphology and specific surface area of the material.

Understanding the Trade-offs

Batch vs. Continuous Processing

While vacuum ovens offer superior quality control, they are typically batch-process devices.

You must load the chamber, seal it, pump it down, process, and repressurize. This is generally more labor-intensive and may have lower throughput compared to continuous conveyor-belt standard ovens used in high-volume manufacturing.

Equipment Complexity

Vacuum drying requires a sealed system and a vacuum pump, which introduces more mechanical complexity than a simple heating element and fan.

This requires diligent maintenance of seals and pump oil to ensure the vacuum levels remain consistent enough to achieve the desired boiling point depression.

Making the Right Choice for Your Goal

To maximize the performance of your BiFeO3 electrodes, align your drying method with your specific technical requirements:

- If your primary focus is Chemical Purity: Use vacuum drying to eliminate oxygen exposure and prevent the oxidation of active materials during the heating phase.

- If your primary focus is Structural Stability: Rely on vacuum drying to lower the boiling point of solvents, preventing thermal stress cracks and preserving surface active sites.

- If your primary focus is Adhesion: Utilize the vacuum process to ensure thorough solvent removal from the current collector interface, enhancing mechanical bonding.

By controlling pressure as precisely as you control temperature, you ensure that the electrode's physical structure supports its electrochemical potential.

Summary Table:

| Feature | Vacuum Drying Oven (60 °C) | Standard Convection Oven |

|---|---|---|

| Oxidation Risk | Extremely Low (Low-oxygen environment) | High (Oxygen exposure at heat) |

| Solvent Boiling Point | Reduced (Via pressure control) | High (Requires more heat) |

| Material Morphology | Preserved (Static environment) | Risk of disturbance (Airflow) |

| Drying Uniformity | High (Prevents surface cracking) | Moderate (Risk of 'skinning') |

| Structural Integrity | Excellent (Low thermal stress) | Variable (Potential thermal degradation) |

Elevate Your Electrode Performance with KINTEK

Precision in drying is the key to unlocking the full electrochemical potential of BiFeO3 electrode sheets. At KINTEK, we understand that maintaining chemical purity and structural integrity requires more than just heat; it requires controlled environments.

Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, and CVD systems, all customizable for your unique lab requirements. Whether you are aiming to prevent oxidation or ensure superior binder adhesion, our systems provide the stability your research demands.

Ready to optimize your thermal processing? Contact us today to discuss your custom furnace needs with our technical specialists!

Visual Guide

References

- Anders Brennhagen, Helmer Fjellvåg. Unraveling the (De)sodiation Mechanisms of BiFeO<sub>3</sub> at a High Rate with <i>Operando</i> XRD. DOI: 10.1021/acsami.3c17296

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are high-purity alumina crucibles selected as the substrate during the sintering of boron-containing stainless steel?

- Why Is a High-Precision Heating and Stirring Platform Necessary for ZnO Sol-Gel Synthesis? Achieve Perfect Nanoparticles

- How do specialized molds or supports contribute to the standardization of sludge samples? Unlock Precision in Drying

- How does the SOM method enhance titanium alloy purity? The Power of Solid Electrolyte Tubes

- What are the reasons for using high-purity alumina material for the reaction tubes in a Drop Tube Furnace? - Guide

- What is the importance of using external thermometers for lead bath monitoring? Ensure Precision in Chemical Refining

- Why must a high-purity quartz boat be used for Co-Fe-NC catalyst pyrolysis? Ensure Peak Catalyst Purity

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability