The Solid Oxygen-ion Membrane (SOM) method enhances purity through precise physical isolation. By utilizing a solid electrolyte tube—typically made of zirconia—to separate the anode from the molten salt electrolyte, the system creates a highly selective barrier. This barrier permits only oxygen ions to migrate to the anode while blocking other anions, effectively preventing cross-contamination and the formation of impurities in the final titanium alloy.

The SOM method replaces the open electrolytic environment with a closed, selective system. By isolating the anode behind an oxygen-permeable membrane, it eliminates the cross-contamination pathway common in other methods, ensuring a significantly higher purity titanium alloy.

The Mechanism of Anodic Isolation

To understand the purity advantage, one must look at how the SOM method restructures the electrolytic cell.

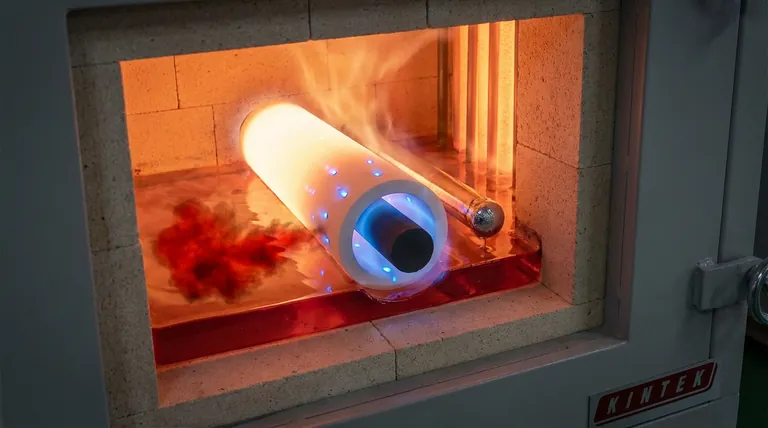

The Zirconia Barrier

The core innovation is the introduction of a solid oxygen-ion conducting membrane tube. This component creates a physical wall between the anode (composed of metal or carbon) and the molten salt electrolyte.

Selective Ion Migration

This membrane is not merely a separator; it is an active filter. It is engineered to allow only oxygen ions to migrate through its structure to reach the anode. This selectivity is the primary driver of the method's efficiency.

Blocking Unwanted Anions

Because the membrane is selective, it physically blocks other anions present in the molten salt from reaching the anode. In standard processes without this tube, these anions would discharge freely, initiating unwanted chemical reactions.

Preventing Chemical Contamination

The isolation provided by the SOM tube directly addresses the chemical byproducts that degrade titanium purity.

Eliminating Harmful Gas Production

In non-isolated systems, the discharge of various anions often results in the production of harmful gases, such as chlorine. By blocking these anions from the anode, the SOM method effectively stops the generation of these hazardous byproducts.

Breaking the Contamination Cycle

A major issue in titanium electrolysis is the migration of anode impurities back toward the cathode. This "back-migration" re-contaminates the titanium being produced.

Ensuring Cathode Purity

The SOM tube acts as a one-way street for oxygen removal. It physically isolates the anode byproducts, making it impossible for them to drift back into the molten salt and contaminate the cathode product.

Understanding the Trade-offs

While the SOM method offers superior purity, the reliance on the solid electrolyte tube introduces specific operational considerations.

Reliance on Membrane Integrity

The entire purification process hinges on the structural integrity of the zirconia tube. If the membrane cracks or degrades, the isolation is lost, and the system reverts to a mixed electrolytic state, compromising purity.

Material Selectivity Limitations

The efficiency of the process is strictly limited by the membrane's conductivity. The tube must maintain high selectivity for oxygen ions over long durations; any material failure leads to immediate process contamination.

Making the Right Choice for Your Goal

The decision to utilize the SOM method largely depends on your tolerance for impurities and your environmental safety requirements.

- If your primary focus is Maximum Alloy Purity: The SOM method is superior because it physically prevents anode impurities from re-contaminating the titanium product.

- If your primary focus is Environmental Safety: The SOM method is ideal as it blocks the discharge of anions that create harmful gases like chlorine.

The SOM method fundamentally upgrades titanium extraction from a mixed chemical bath to a controlled, selective process, guaranteeing a cleaner and safer production cycle.

Summary Table:

| Feature | SOM Method (Solid Electrolyte Tube) | FFC / Standard Electrolysis |

|---|---|---|

| Anode Isolation | Physical barrier (Zirconia tube) | Open electrolytic environment |

| Ion Selectivity | Highly selective for oxygen ions | Non-selective anion migration |

| Contamination Risk | Low (prevents impurity back-migration) | High (anode byproducts reach cathode) |

| Byproduct Control | Blocks harmful gas formation (e.g., Chlorine) | Generates hazardous gas byproducts |

| Key Outcome | Superior purity titanium alloys | Potential for chemical cross-contamination |

Elevate your material processing with KINTEK’s advanced thermal technology. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, and Vacuum systems customizable for complex metallurgical processes like titanium extraction. Ensure the integrity of your research and production with our specialized high-temp furnaces—contact our experts today to find your perfect solution!

References

- Yuhang Miao, Jinming Hu. Research Progress of Preparing Titanium Alloy By Molten Salt Method. DOI: 10.62051/ijnres.v2n1.30

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- Why is temperature resistance important for alumina ceramic furnace tubes? Ensure Safety and Performance in High-Temp Processes

- What is the critical role of a mechanical vacuum pump in WS2 gas sensor prep? Ensure High Purity & Performance

- What is the function of a water-cooled jacket on a sampling probe? Optimize Atomization and Protect Hardware

- Why is a high-performance vacuum pumping system necessary for industrial alloys? Ensure Purity & Peak Performance

- Why are evaporators and condensers required for zirconium tetrachloride purification? Mastering Nuclear-Grade Standards

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What environmental conditions do vacuum systems and quartz tubes provide? Optimize ZnS Nanobelt Synthesis

- What is the function of precision magnetic heating stirring equipment in BCZT ceramic preparation? Achieve Homogeneity