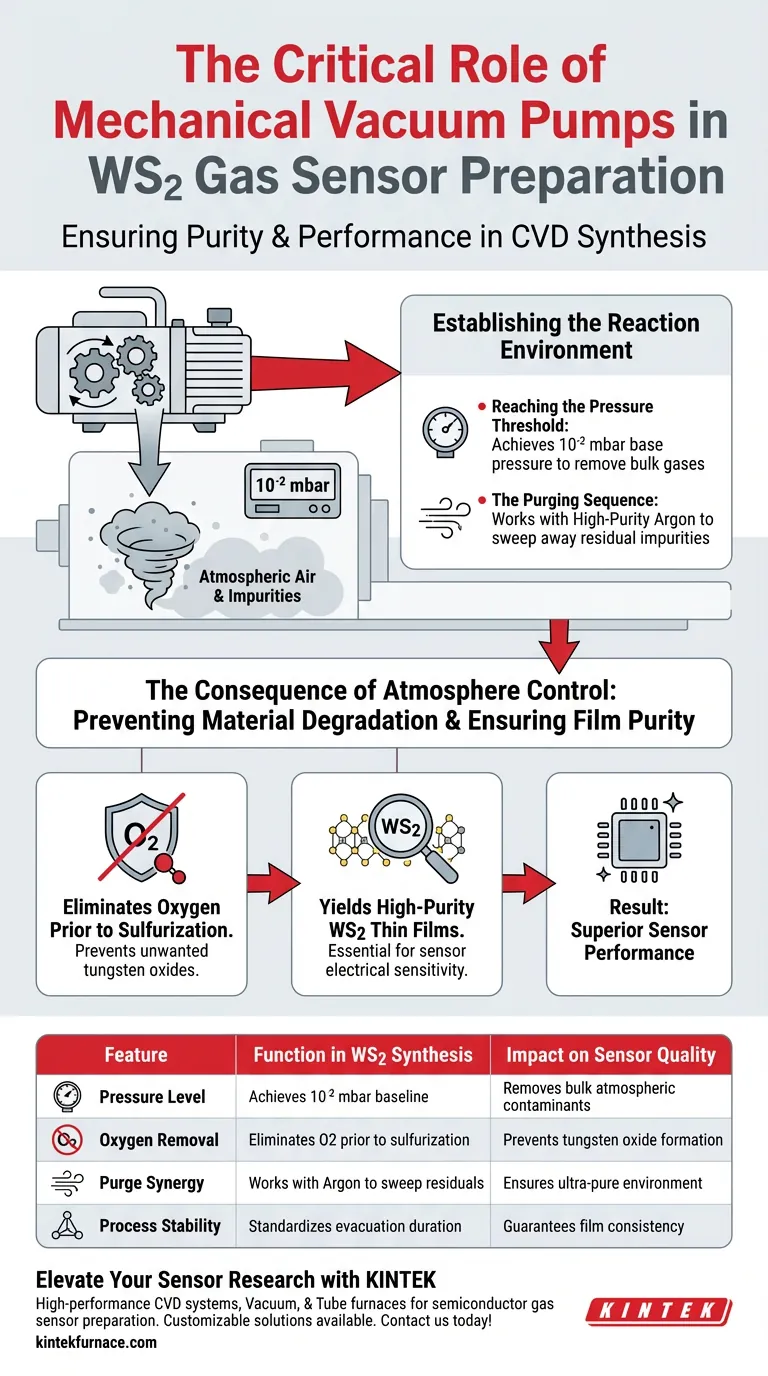

The mechanical vacuum pump serves as the foundational tool for purity in the preparation of tungsten disulfide (WS2) gas sensors. Its critical function is to pre-evacuate the chemical vapor deposition (CVD) reactor to a specific pressure of approximately 10⁻² mbar. By removing atmospheric air and residual impurities, it establishes the baseline conditions necessary for a controlled synthesis environment.

The vacuum pump eliminates oxygen prior to sulfurization, preventing the formation of unwanted tungsten oxides and ensuring the production of high-purity WS2 thin films.

Establishing the Reaction Environment

Reaching the Pressure Threshold

The synthesis of WS2 requires a pristine starting environment. The mechanical pump is responsible for drawing the reactor chamber down to a base pressure of 10⁻² mbar.

This specific pressure level is sufficient to remove the bulk of atmospheric gases that would otherwise interfere with the chemical reaction.

The Purging Sequence

Evacuation alone is often not enough to guarantee purity. The vacuum step is immediately followed by a purge using high-purity argon.

The mechanical pump works in tandem with this inert gas flow. Together, they sweep away any stubborn residual impurities lingering in the chamber.

The Consequence of Atmosphere Control

Preventing Material Degradation

The primary adversary in WS2 sensor preparation is oxygen. If oxygen is present during the high-temperature sulfurization process, the tungsten precursor will oxidize.

This results in the formation of tungsten oxides rather than the desired tungsten disulfide.

Ensuring Film Purity

The mechanical pump ensures the sulfurization occurs in a strictly controlled atmosphere.

By maintaining low oxygen levels, the process yields WS2 thin films that are virtually free of oxides. This chemical purity is essential for the electrical sensitivity and performance of the final gas sensor.

Common Pitfalls to Avoid

Insufficient Evacuation Time

A common error is rushing the pre-evacuation phase.

If the pump is not allowed to stabilize the chamber at 10⁻² mbar, pockets of air may remain. This leads to inconsistent film quality and "islands" of oxidation within the sensor material.

Relying Solely on Argon

Purging with argon without a prior vacuum drawdown is ineffective.

The mechanical pump is required to physically remove the volume of air first. Argon acts as a finishing rinse, not a replacement for mechanical evacuation.

Making the Right Choice for Your Goal

To maximize the performance of your WS2 gas sensors, consider the following operational priorities:

- If your primary focus is film purity: Ensure the mechanical pump achieves a stable 10⁻² mbar baseline before introducing any precursor gases.

- If your primary focus is consistency: Standardize the exact duration of the vacuum drawdown and argon purge for every batch to prevent batch-to-batch variation.

The mechanical vacuum pump is the critical gatekeeper that allows high-quality semiconductor growth to occur.

Summary Table:

| Feature | Function in WS2 Synthesis | Impact on Sensor Quality |

|---|---|---|

| Pressure Level | Achieves 10⁻² mbar baseline | Removes bulk atmospheric contaminants |

| Oxygen Removal | Eliminates O2 prior to sulfurization | Prevents unwanted tungsten oxide formation |

| Purge Synergy | Works with Argon to sweep residuals | Ensures ultra-pure synthesis environment |

| Process Stability | Standardizes evacuation duration | Guarantees film consistency and sensitivity |

Elevate Your Sensor Research with KINTEK

Precision in WS2 synthesis begins with a controlled environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance CVD systems, Vacuum, and Tube furnaces specifically designed to meet the rigorous demands of semiconductor gas sensor preparation.

Whether you need a standard setup or a customizable system tailored to your unique research needs, our team is here to support your innovation.

Ready to achieve superior film purity and consistency? Contact us today to find your solution!

Visual Guide

References

- Thin Films of Tungsten Disulfide Grown by Sulfurization of Sputtered Metal for Ultra-Low Detection of Nitrogen Dioxide Gas. DOI: 10.3390/nano15080594

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the function of a copper turning purification device? Enhance Your Sintering Furnace Gas Purity

- How does the optical clarity of quartz tubes benefit laboratory processes? Enhance Control and Accuracy in High-Temp Experiments

- What is the technical role of a magnetic stirring hot plate in synthesis? Optimize Cobalt Oxide Nanoparticle Quality

- Why are high-alumina crucibles required for static immersion corrosion tests? Ensure Data Purity at 1000°C

- What voltage options are available for the water circulating vacuum pump? Choose the Right Voltage for Your Lab

- Why must high-pressure microwave reaction vessels maintain excellent sealing performance? Ensure Carbon Synthesis Success

- What are alumina ceramic tubes and why are they considered advanced ceramics? Discover High-Performance Solutions for Extreme Environments

- How does an in-situ reaction chamber in HTXRD facilitate BiFeO3 synthesis study? Mapping Real-Time Phase Evolution