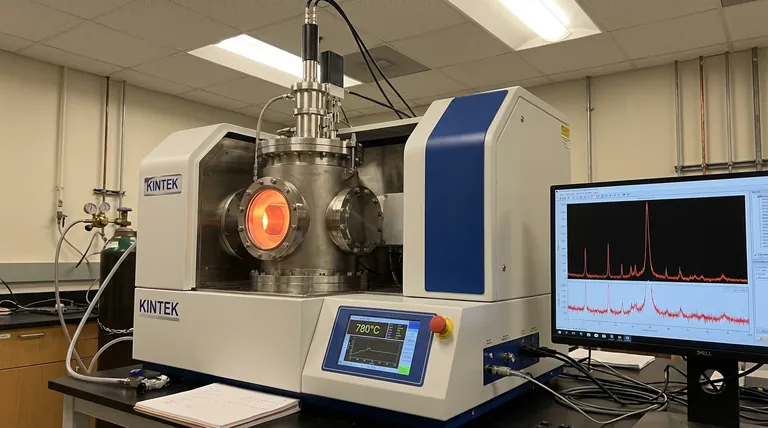

An in-situ reaction chamber serves as a precise thermal stage within the High-Temperature X-ray Diffraction (HTXRD) system, enabling the direct, continuous monitoring of chemical synthesis. By providing a controlled environment that ramps from room temperature up to 780°C at specific rates (such as 1°C/min), it allows researchers to observe the exact moment precursor materials react to form intermediates and final products.

Core Takeaway The in-situ chamber eliminates the guesswork of post-reaction analysis by capturing the "live" synthesis process. Its primary value lies in revealing the dynamic formation of the key intermediate Bi25FeO39, providing a definitive map of the reaction pathway from precursors to the final BiFeO3 phase.

Unlocking Dynamic Reaction Mechanisms

Precision Thermal Control

The reaction chamber is designed to maintain a highly stable thermal environment. It supports heating protocols from room temperature up to 780°C.

Crucially, the system allows for slow, deliberate heating rates, specifically 1°C/min.

This gradual temperature increase is essential for maintaining thermal equilibrium, ensuring that the X-ray data collected accurately reflects the material's state at that specific moment.

Real-Time Phase Evolution

Unlike ex-situ methods, which analyze samples only after they have been heated and cooled, the in-situ chamber captures the process as it happens.

This provides a continuous view of the interaction between the starting precursors, alpha-Bi2O3 and Fe2O3.

Researchers can visually track the decline of these precursors and the emergence of new structures in real-time.

Capturing Critical Intermediates

The Formation of Bi25FeO39

The most significant capability of this setup is the detection of transient phases that might vanish upon cooling.

Specifically, the system identifies the formation of Bi25FeO39, a key intermediate compound.

Capturing this phase confirms the step-by-step reaction mechanism required to synthesize the final BiFeO3 product.

Eliminating Post-Reaction Ambiguity

Reliance on post-reaction comparisons often leads to gaps in understanding how a material was formed.

The in-situ chamber removes this ambiguity by recording the exact temperature and timeframe in which phase changes occur.

This moves the science from hypothesizing about the reaction path to empirically observing it.

Understanding the Trade-offs

Time Intensity

Utilizing a heating rate of 1°C/min to reach high temperatures is an inherently slow process.

Obtaining high-resolution data on intermediates requires a significant investment of instrument time per sample compared to rapid ex-situ firing.

Data Complexity

The continuous collection of diffraction patterns generates a massive dataset.

Isolating the peaks of an intermediate like Bi25FeO39 amidst decaying precursor signals requires careful analysis to distinguish signal from noise.

Making the Right Choice for Your Research

To maximize the utility of an in-situ HTXRD study, align the chamber's capabilities with your specific synthesis goals.

- If your primary focus is mechanism validation: Use the slow heating rate (1°C/min) to ensure you capture the brief appearance of intermediates like Bi25FeO39.

- If your primary focus is process optimization: Use the real-time data to pinpoint the exact temperature where the reaction completes to avoid overheating in production.

By transforming synthesis from a "black box" into a visible timeline, the in-situ chamber provides the data necessary to control and optimize complex material formation.

Summary Table:

| Feature | Specification/Detail | Research Value |

|---|---|---|

| Temperature Range | RT to 780°C | Enables study of high-temp phase transitions |

| Heating Rate | 1°C/min (Slow Ramp) | Ensures thermal equilibrium for peak accuracy |

| Key Intermediate | Bi25FeO39 | Captures transient phases missing in ex-situ |

| Precursor Focus | alpha-Bi2O3 & Fe2O3 | Monitors real-time decay and reaction path |

| Data Type | Continuous XRD Patterns | Eliminates post-reaction analysis ambiguity |

Elevate Your Material Research with KINTEK Precision

Are you looking to eliminate the 'black box' of material synthesis? KINTEK provides industry-leading thermal solutions, including customizable Muffle, Tube, Rotary, and Vacuum furnaces, alongside advanced CVD systems designed for the most demanding lab environments.

Backed by expert R&D and manufacturing, our high-temperature systems are tailored to help you achieve precise thermal control and observe critical reaction mechanisms like BiFeO3 synthesis with unrivaled accuracy.

Ready to optimize your synthesis workflow? Contact us today to discuss your unique research needs and discover how our customizable furnaces can empower your next breakthrough!

References

- Corrado Wesley, Jacob L. Jones. Solid state synthesis of BiFeO <sub>3</sub> occurs through the intermediate Bi <sub>25</sub> FeO <sub>39</sub> compound. DOI: 10.1111/jace.19702

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the advantages of using a single-mode microwave generator? Precision Heating for Metal Recovery

- Why is a MgO crucible preferred for VCD? Achieve 3ppm Purity in High-Temperature Metallurgy

- Why is a high-performance vacuum pumping system necessary for industrial alloys? Ensure Purity & Peak Performance

- What functions does a high-density graphite crucible perform? More Than a Container for Copper Refining

- Why is the use of high-purity graphite crucibles essential? Protect TiC-High Manganese Steel During Sintering

- What is the significance of using a vacuum saturation device for AAS concrete? Ensure Valid Chloride Ion Testing

- What role do high-strength graphite molds play during SPS of Ti-6Al-4V alloy? Mastering Thermal & Mechanical Control

- Why is a laboratory pellet press used to compress powders? Optimize Conductivity for Flash Joule Heating