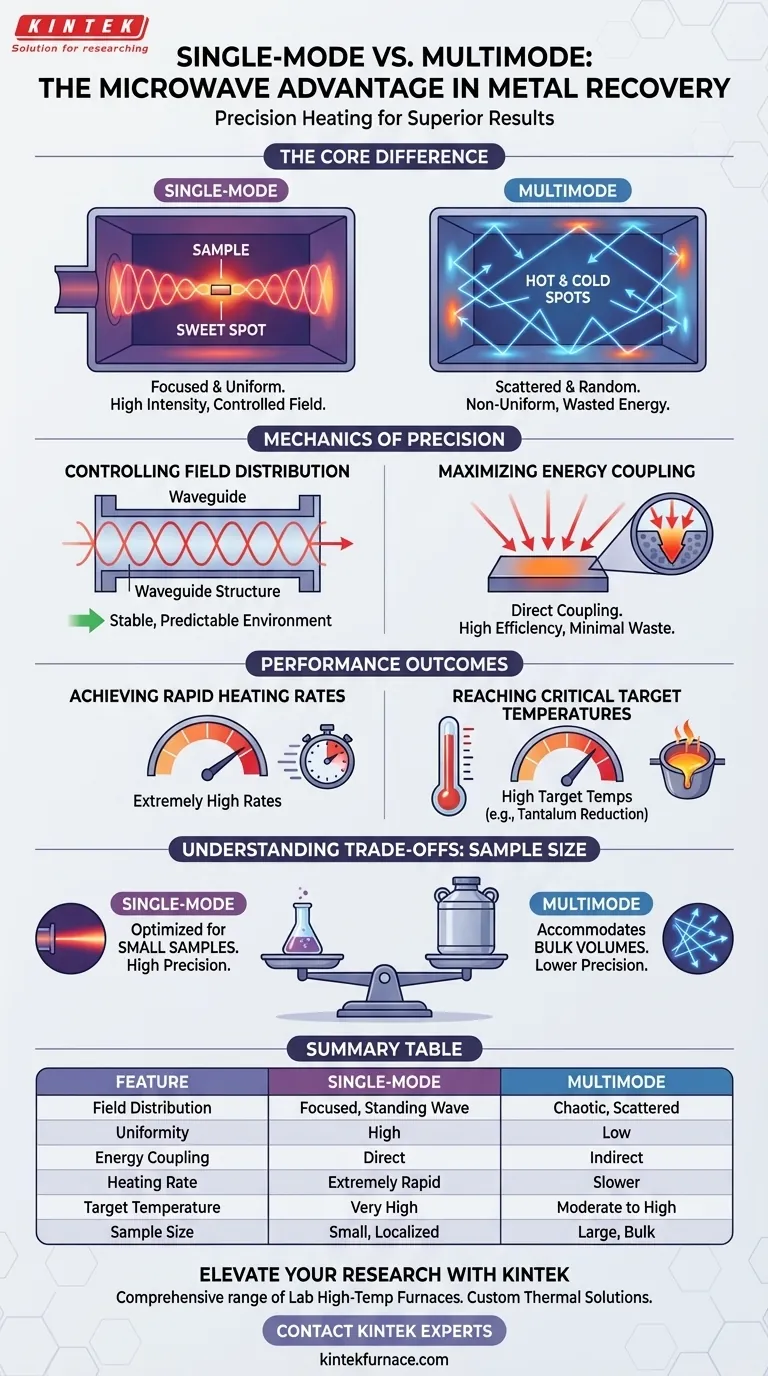

The primary advantage of a single-mode microwave generator is its ability to create a highly focused and uniform electromagnetic field, significantly outperforming the scattered distribution of standard multimode systems. By channeling energy through a specific waveguide structure, the system precisely targets the sample, ensuring that the maximum amount of energy is coupled directly to the material rather than being wasted in the cavity.

The core difference lies in control: multimode systems create random "hot and cold spots," whereas single-mode generators concentrate energy into a specific, high-intensity zone. This precision enables the extreme heating rates and temperatures required for complex chemical processes, such as the selective reduction of tantalum.

The Mechanics of Precision Heating

Controlling Field Distribution

Standard multimode systems operate by bouncing microwaves chaotically within a cavity. This often results in non-uniform field strength distributions, meaning some parts of your sample may overheat while others remain under-processed.

In contrast, a single-mode generator utilizes a specific waveguide structure to create a standing wave pattern. This engineered approach eliminates chaotic scattering, providing a stable and predictable electromagnetic environment for the experiment.

Maximizing Energy Coupling

The geometry of a single-mode system allows the user to place the sample at the exact location of maximum field intensity. The reference notes that this setup precisely couples energy onto small samples located at the center of the reaction chamber.

This direct coupling ensures high efficiency. Instead of heating the air or the chamber walls, the electromagnetic energy is absorbed almost exclusively by the target metal, driving the reaction forward with minimal waste.

Performance Outcomes in Metal Recovery

Achieving Rapid Heating Rates

For metal recovery, speed often dictates the success of the reaction. The focused intensity of a single-mode system allows for extremely high heating rates that multimode systems simply cannot match. This rapid rise in temperature is essential for overcoming high activation energy barriers quickly.

Reaching Critical Target Temperatures

Certain metallurgical processes require extreme heat to facilitate reduction. The single-mode design enables the sample to reach high target temperatures that might be unattainable in a dispersed multimode field. This thermal capability is identified as critical for applications such as the selective reduction of metals like tantalum.

Understanding the Trade-offs

Sample Size Limitations

While single-mode generators offer superior control, they are constrained by volume. The high-intensity "sweet spot" created by the waveguide is physically small.

Consequently, these systems are optimized for small samples. If an experiment requires processing large bulk volumes of material simultaneously, the focused nature of the single-mode field becomes a limitation rather than an asset.

Making the Right Choice for Your Experiment

Selecting the correct microwave system depends entirely on the specific requirements of your metal recovery process.

- If your primary focus is reaction precision and temperature: Choose a single-mode generator to ensure the uniform, high-intensity field required for chemically sensitive reductions.

- If your primary focus is bulk volume throughput: A multimode system may be more appropriate, provided you can accommodate slower heating rates and uneven temperature distribution.

For high-stakes recovery experiments where thermal control is paramount, the single-mode generator remains the definitive choice.

Summary Table:

| Feature | Single-Mode Microwave Generator | Multimode Microwave System |

|---|---|---|

| Field Distribution | Focused, standing wave pattern | Chaotic, scattered distribution |

| Uniformity | High (eliminates hot/cold spots) | Low (random hot/cold spots) |

| Energy Coupling | Direct, maximum coupling on sample | Indirect, energy wasted in cavity |

| Heating Rate | Extremely rapid | Slower, dispersed |

| Target Temperature | Very high (e.g., for tantalum reduction) | Moderate to high |

| Sample Size | Small, localized samples | Large, bulk volumes |

Elevate Your Metallurgical Research with KINTEK

Precision is non-negotiable in metal recovery. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need the focused intensity of single-mode technology or a customized thermal solution for your unique research needs, our engineers are here to help.

Maximize your lab's efficiency and achieve critical reaction temperatures with KINTEK. Contact our experts today to find your perfect system!

Visual Guide

References

- Ansan Pokharel, Terence Musho. Microwave-assisted recycling of tantalum and manganese from end-of-life tantalum capacitors. DOI: 10.1038/s41598-025-96574-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of using a laboratory electric thermostatic blast drying oven for biomass briquette moisture control?

- Why is a cylindrical mold made of SS400 steel utilized for slag casting experiments? Explained

- How do vacuum systems assist in pure thin film growth? Enhance PLD Chemical Purity with Turbo-Molecular Pumps

- What role does a high-purity quartz tube play in flash Joule heating? Ensure Safety and Process Control

- What role does a planetary ball mill play in Al-Cr-Cu-Fe-Mn-Ni alloy prep? Master Mechanical Alloying Efficiency

- Why use a PLC and touch screen for magnesium vacuum distillation? For Superior Control and Safety

- What is the function of the circulating water cooling system? Optimize Pyrolysis Oil Condensation and Yield

- What is the function of a vacuum drying oven for biochar FTIR analysis? Ensure High-Purity Sample Preparation