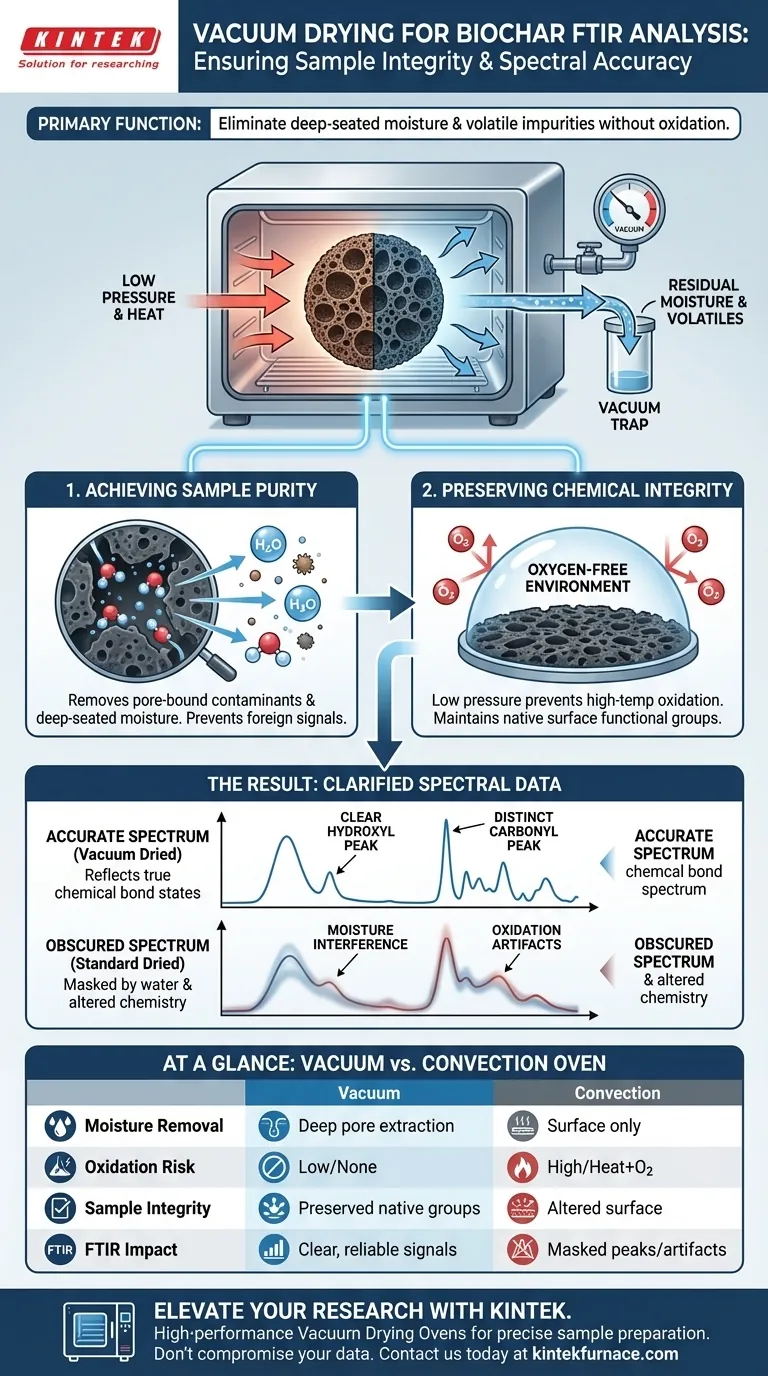

The primary function of a vacuum drying oven is to eliminate residual moisture and volatile impurities trapped within the porous structure of biochar-based composite materials. By applying heat in a low-pressure environment, this equipment prepares the sample for Fourier Transform Infrared (FTIR) spectroscopy without exposing it to the damaging effects of high-temperature oxidation.

Core Takeaway: Vacuum drying is essential for preserving the true chemical identity of a sample. It ensures that the spectral data you capture reflects the actual material properties, rather than artifacts caused by trapped water or oxidative degradation during the drying process.

The Necessity of Sample Purity

Removing Pore-Bound Contaminants

Biochar composites are highly porous materials that naturally trap residual moisture and volatile impurities. If these substances remain during analysis, they introduce foreign signals that obscure the material's actual chemical composition.

Targeting Deep-Seated Moisture

Standard surface drying is often insufficient for porous biochar. A vacuum drying oven creates a pressure differential that draws moisture out from deep within the pores of the material, ensuring a thoroughly dry sample.

Preserving Chemical Integrity

The Danger of Oxidation

Heat is necessary to drive off moisture, but heat in the presence of oxygen often leads to high-temperature oxidation. This reaction alters the surface chemistry of the biochar, creating new chemical groups that did not exist in the original sample.

Utilizing Low-Pressure Conditions

By operating under low-pressure conditions, the vacuum oven removes the oxygen required for oxidation to occur. This allows you to apply the necessary thermal energy to dry the sample while strictly maintaining the material's original surface functional groups.

Ensuring Spectral Accuracy

Clarifying Chemical Signals

FTIR spectroscopy relies on detecting specific bond vibrations. The vacuum drying process ensures that the resulting spectrum accurately reflects the true chemical bond states of the biochar composite.

Differentiating Critical Peaks

Accurate preparation is vital for distinguishing between genuine structural elements and contaminants. Specifically, this process clarifies hydroxyl and carbonyl peaks, ensuring that the data reflects the material's actual state—whether before or after aging and chemical reactions—rather than moisture interference or oxidation artifacts.

Common Pitfalls to Avoid

The Risk of Standard Drying

Using a conventional convection oven instead of a vacuum oven is a common error. While it removes water, the presence of atmospheric oxygen at high temperatures can oxidize the biochar surface, fundamentally changing the sample before it ever reaches the FTIR instrument.

Misinterpreting Hydroxyl Peaks

Failure to thoroughly remove moisture can lead to data misinterpretation. Residual water creates strong, broad hydroxyl absorption bands in FTIR spectra, which can easily be mistaken for or mask the actual hydroxyl groups inherent to the biochar structure.

Optimizing Your Preparation Protocol

To ensure your FTIR data is both accurate and reproducible, apply the vacuum drying method strategically based on your analytical goals:

- If your primary focus is Surface Chemistry: Prioritize the vacuum setting to prevent oxidation, ensuring that the functional groups you detect are native to the material and not artifacts of the preparation.

- If your primary focus is Spectral Clarity: Ensure sufficient drying time under vacuum to fully evacuate pore-bound water, preventing moisture signals from overwhelming critical hydroxyl or carbonyl peaks.

By strictly controlling the drying environment, you transform your sample preparation from a routine step into a quality assurance measure for your data.

Summary Table:

| Feature | Vacuum Drying Oven | Conventional Convection Oven |

|---|---|---|

| Moisture Removal | Deep extraction from internal pores | Primarily surface-level drying |

| Oxidation Risk | Minimal (Oxygen-free environment) | High (Heat + atmospheric oxygen) |

| Sample Integrity | Preserves native functional groups | Risks altering surface chemistry |

| FTIR Impact | Clear, reliable spectral signals | Masked peaks due to moisture/artifacts |

| Primary Benefit | Precise hydroxyl & carbonyl analysis | Faster but less accurate for porous media |

Elevate Your Materials Research with KINTEK

Precise FTIR analysis starts with flawless sample preparation. At KINTEK, we understand that preserving the chemical integrity of biochar and porous composites is critical for your research success. Backed by expert R&D and world-class manufacturing, we provide high-performance Vacuum Drying Ovens, along with Muffle, Tube, Rotary, and CVD systems designed to meet the most rigorous laboratory standards.

Whether you need a standard solution or a customizable high-temp furnace tailored to your unique research needs, our team is ready to support your laboratory's efficiency. Don't let oxidation or residual moisture compromise your data.

Contact KINTEK Today for a Professional Consultation

Visual Guide

References

- Chathuri Peiris, Todd Mlsna. Comparative Study of Biocarbon-Supported Iron Nanoparticle Composites (nZVI@BC) Synthesized by Carbothermal Versus Borohydride Reductions for Heavy Metal Removal. DOI: 10.1021/acssusresmgt.5c00250

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do Mass Flow Controllers (MFC) contribute to the repeatability of In2Se3 synthesis? Master CVD Process Stability

- What is the maximum vacuum capacity of the water circulating vacuum pump? Uncover Its Ideal Lab Applications

- What functions do high-purity sulfur powder and ceramic boats serve in TB-MoS2 prep? Precision in 2D Material Synthesis

- Why are desiccators containing saturated salt solutions used when evaluating the hygroscopicity of modified wood?

- Why is a heating device with magnetic stirring required for Y2O3-MgO precursors? Ensure Perfect Particle Coating

- What is the role of a BN crucible in Ca0.5Sr0.5AlSiN3:Eu2+ synthesis? Achieve High-Purity Nitride Phosphors

- Are customization options available for alumina ceramic furnace tubes? Tailor Them for Your Lab's Needs

- What customization options are available for alumina ceramic tubes? Tailor for High-Temp, Corrosion-Resistant Applications