Yes, alumina ceramic tubes are extensively customizable to meet precise industrial and scientific requirements. Beyond standard stock sizes, you can specify dimensions, shapes, and add functional features to ensure the tube integrates perfectly into your high-performance application.

Customization is not just about fit; it's a critical engineering step. It allows you to fully leverage alumina's exceptional properties—like high-temperature stability and chemical inertness—by precisely tailoring the component to the unique stresses of its intended environment.

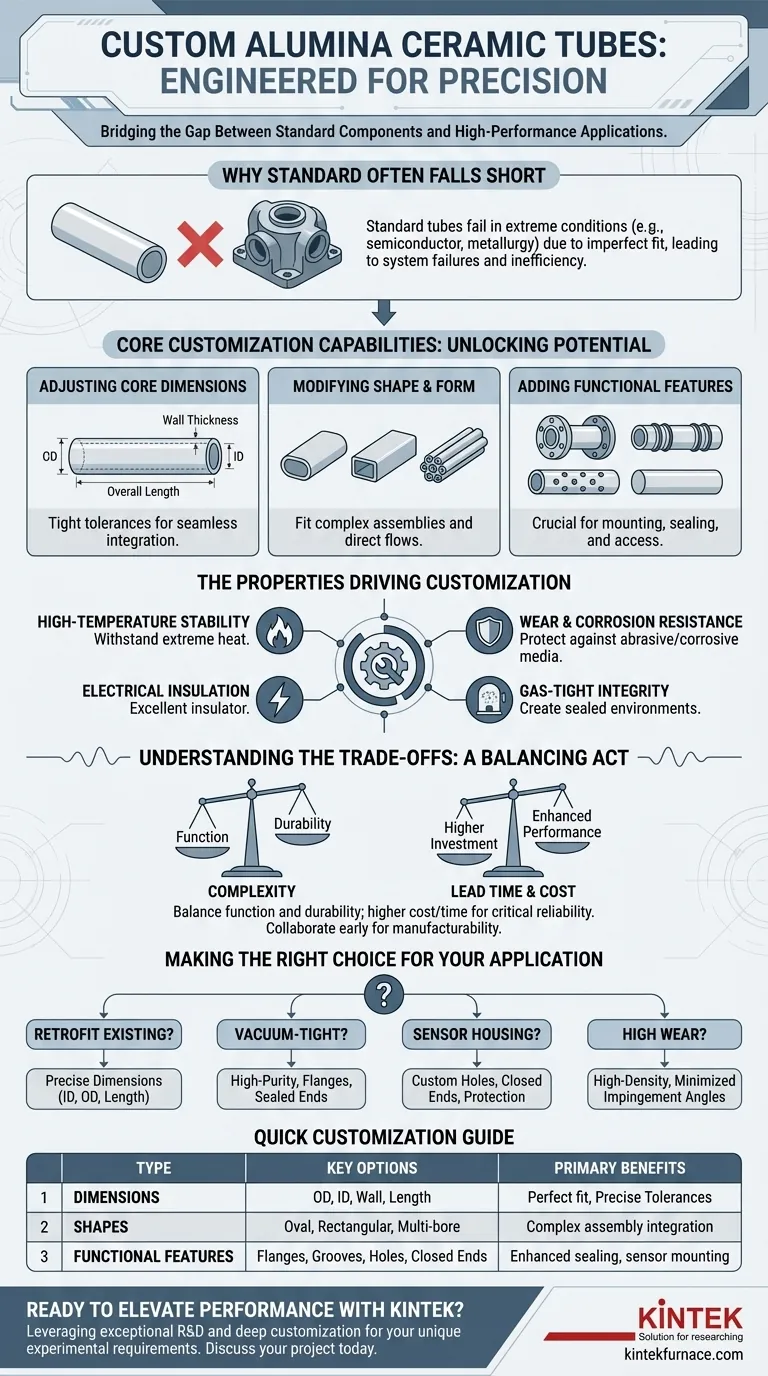

Why Standard Tubes Often Fall Short

Standard, off-the-shelf components are designed for general use. However, advanced applications in fields like semiconductor manufacturing, metallurgy, and laboratory analysis operate under extreme conditions that demand a perfect fit.

A standard tube may not match the port size of a vacuum furnace, the path of a process gas, or the mounting points for sensors. Customization bridges this gap, preventing system failures, ensuring process integrity, and maximizing efficiency.

Core Customization Capabilities

The manufacturing process for alumina ceramics allows for significant modification before the final sintering (firing) stage. This flexibility enables a wide range of tailored designs.

Adjusting Core Dimensions

The most common customization involves specifying the tube's dimensions. This ensures it fits seamlessly into existing equipment. Key dimensional options include outer diameter (OD), inner diameter (ID), wall thickness, and overall length.

Manufacturers can produce tubes to tight tolerances, accommodating both standard American and international metric measurements.

Modifying Shape and Form

Alumina tubes are not limited to simple cylinders. They can be formed into various shapes to direct flows, fit complex assemblies, or perform specialized functions. This includes oval, rectangular, or multi-bore "spaghetti" tubes for housing separate wires or thermocouples.

Adding Functional Features

Specific features can be machined into the pre-sintered ("green") ceramic. These additions are crucial for mounting, sealing, and creating access points.

Common features include:

- Flanges: For creating a robust, gas-tight seal in vacuum or high-pressure systems.

- Grooves: For seating O-rings or retaining clips.

- Holes: Drilled радиально or axially to serve as burner holes, gas inlets, or lead-outs for electrical cables and sensors.

- Closed Ends: One end can be formed into a closed, rounded dome, creating a protective sheath for a thermocouple or a crucible for high-temperature reactions.

The Properties Driving the Need for Customization

The demand for custom alumina tubes is a direct result of their elite material properties. Each property solves a critical challenge in harsh environments, and customization unlocks their full potential.

High-Temperature Stability

Alumina is renowned for its ability to withstand extreme heat, making it essential for furnace tubes and kiln components. Customizing the length and diameter ensures the tube perfectly lines the furnace's hot zone, providing a stable and protective environment.

Wear and Corrosion Resistance

In industries like float glass and chemical processing, components are exposed to abrasive materials and corrosive chemicals. A custom-shaped tube can protect critical sensors or transfer aggressive media without degrading, ensuring process purity and long service life.

Electrical Insulation and Gas-Tight Integrity

Alumina is an excellent electrical insulator and can be made gas-tight. Custom tubes with precisely placed holes and flanges are critical for creating high-vacuum chambers, acting as electrical feedthroughs, or providing a controlled atmosphere for sintering advanced materials.

Understanding the Trade-offs

While customization offers immense benefits, it's important to approach it with a clear understanding of the engineering and logistical implications.

Complexity vs. Mechanical Strength

Adding features like sharp corners or holes can create stress concentration points. While manufacturers engineer for this, overly complex designs may compromise the tube's inherent mechanical strength and thermal shock resistance. It's a balance between function and durability.

Lead Time and Cost

Custom tooling and individual fabrication processes mean that customized tubes will have a longer lead time and higher cost than standard, in-stock items. This investment is justified by the enhanced performance and reliability in a critical application.

Design for Manufacturability

There are physical limitations to what can be manufactured. Extremely thin walls, for example, may be too fragile to survive the sintering process. Collaborating with the manufacturer early in the design phase is key to ensuring your concept is feasible.

Making the Right Choice for Your Application

To select the right customizations, start by defining the primary challenge your component must overcome.

- If your primary focus is retrofitting existing equipment: Prioritize precise dimensional customization (ID, OD, length) to ensure a drop-in replacement.

- If your primary focus is creating a vacuum-tight system: Specify high-purity alumina and work with the manufacturer to design robust flanges and sealed ends.

- If your primary focus is housing sensors or electronics: Concentrate on features like custom-drilled holes for lead-outs and closed-end designs for protection from corrosive or high-temperature environments.

- If your primary focus is managing high wear and abrasion: Select a high-purity, high-density alumina and design a shape that minimizes direct impingementAngles if possible.

By matching the right customization to your specific goal, you transform a simple tube into a high-performance, mission-critical component.

Summary Table:

| Customization Type | Key Options | Primary Benefits |

|---|---|---|

| Dimensions | Outer/Inner Diameter, Wall Thickness, Length | Perfect fit for equipment, precise tolerances |

| Shapes | Oval, Rectangular, Multi-bore Tubes | Complex assembly integration, specialized functions |

| Functional Features | Flanges, Grooves, Holes, Closed Ends | Enhanced sealing, sensor mounting, process control |

Ready to elevate your lab's performance with custom alumina ceramic tubes? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need precise dimensional fits, specialized shapes, or functional features for high-temperature stability and corrosion resistance, we can help. Contact us today to discuss your project and discover how our tailored solutions can optimize your processes and boost efficiency!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications