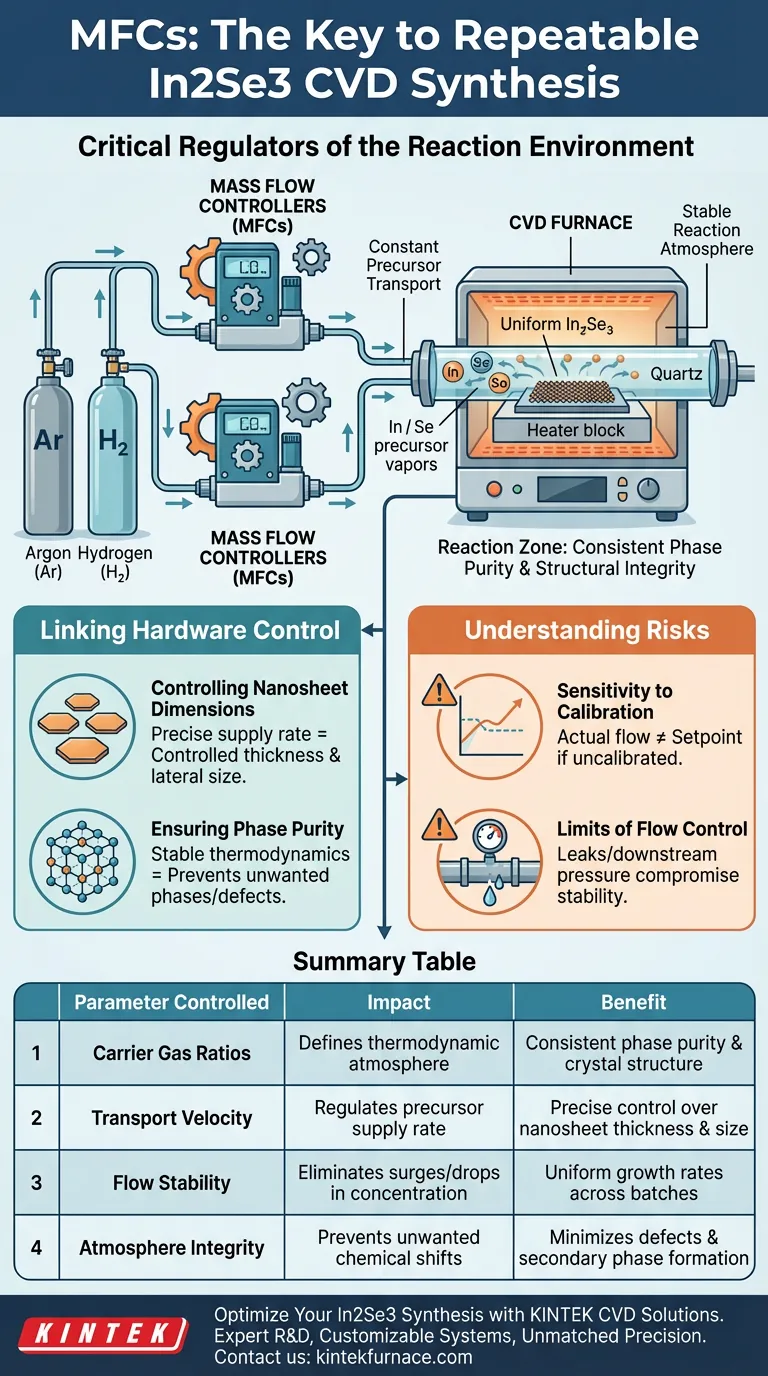

Mass Flow Controllers (MFCs) are the critical regulators of the reaction environment needed for reproducible In2Se3 synthesis. They function by precisely managing the flow rates and specific ratios of carrier gases—typically argon and hydrogen mixtures—to ensure the transport of precursor vapors remains constant throughout the Chemical Vapor Deposition (CVD) process.

The repeatability of your synthesis relies on minimizing variables in the vapor phase. By locking in a stable reaction atmosphere, MFCs directly dictate the structural integrity, thickness, and phase purity of the resulting In2Se3 nanosheets.

The Mechanics of Stability in CVD

To understand how MFCs drive repeatability, you must look at how they influence the kinetics of the reaction inside the chamber.

Precise Regulation of Carrier Gases

The foundation of In2Se3 synthesis is the carrier gas, usually a mixture of argon and hydrogen.

MFCs strictly enforce the ratio between these gases. This is not merely about moving gas; it is about defining the thermodynamic environment in which the reaction occurs.

Constant Precursor Transport

Repeatability requires that the amount of material reaching the substrate is identical in every second of the process.

MFCs ensure a constant transport rate of precursor vapors. By stabilizing the flow of the carrier gas, the MFC prevents surges or drops in the concentration of reactants reaching the growth zone.

Linking Hardware Control to Material Quality

The physical properties of the synthesized In2Se3 are extremely sensitive to the flow parameters controlled by the MFC.

Controlling Nanosheet Dimensions

The geometry of your final product is determined by the supply rate of the source material.

By maintaining a consistent flow, MFCs allow you to precisely control the thickness and lateral size of the nanosheets. Fluctuations in flow would otherwise lead to uneven growth rates and irregular shapes.

Ensuring Phase Purity

In2Se3 can exist in different structural phases, but usually, only one specific phase is desired for a given application.

A stable reaction atmosphere is required to thermodynamically favor the formation of high-phase-purity crystals. MFCs prevent changes in gas composition that could inadvertently shift the reaction conditions and trigger the growth of unwanted phases or defects.

Understanding the Risks and Trade-offs

While MFCs are essential for precision, relying on them requires an understanding of their limitations within the system.

Sensitivity to Calibration

An MFC is only as good as its calibration. If the controller drifts or is calibrated for a gas with a different thermal capacity than the one being used, the actual flow rate will differ from the setpoint.

This discrepancy can lead to "repeatable" errors—where you consistently produce the wrong material because the hardware is consistently inaccurate.

The Limits of Flow Control

MFCs regulate the input, but they cannot compensate for downstream issues.

If there are leaks in the furnace or fluctuations in downstream pressure, the stability provided by the MFC at the inlet may be compromised before the gas reaches the substrate.

How to Apply This to Your Project

To maximize the repeatability of your In2Se3 synthesis, align your flow control strategy with your specific material goals.

- If your primary focus is Nanosheet Thickness: Prioritize the precise regulation of carrier gas velocities to maintain a perfectly constant precursor transport rate.

- If your primary focus is Phase Purity: Focus on the strict maintenance of the Argon/Hydrogen ratio to ensure the reaction atmosphere remains thermodynamically stable.

Mastering the use of Mass Flow Controllers transforms the CVD process from a variable experiment into a controllable manufacturing method.

Summary Table:

| Parameter Controlled | Impact on In2Se3 Synthesis | Benefit for Repeatability |

|---|---|---|

| Carrier Gas Ratios | Defines thermodynamic reaction atmosphere | Consistent phase purity and crystal structure |

| Transport Velocity | Regulates precursor supply rate to substrate | Precise control over nanosheet thickness and size |

| Flow Stability | Eliminates surges or drops in concentration | Uniform growth rates across multiple batches |

| Atmosphere Integrity | Prevents unwanted chemical shifts | Minimizes defects and secondary phase formation |

Optimize Your In2Se3 Synthesis with Precision CVD Solutions

Don't let flow fluctuations compromise your research outcomes. At KINTEK, we understand that repeatability in 2D material synthesis demands absolute control. Our high-performance CVD systems—including specialized Tube, Vacuum, and CVD furnaces—are engineered with advanced Mass Flow Controllers to provide the stable reaction environment your projects require.

Why choose KINTEK?

- Expert R&D & Manufacturing: Industry-leading thermal processing expertise.

- Customizable Systems: Tailored configurations for Muffle, Rotary, and CVD furnaces to meet your unique synthesis needs.

- Unmatched Precision: Designed to ensure the structural integrity and phase purity of your materials.

Ready to elevate your lab's efficiency and material quality? Contact our expert team today to find the perfect customizable furnace solution for your application.

Visual Guide

References

- Fan Zhang, Chenggang Tao. Atomic-scale manipulation of polar domain boundaries in monolayer ferroelectric In2Se3. DOI: 10.1038/s41467-023-44642-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What is the function of a high-purity Argon (Ar) gas flow control system? Ensure Superior Nanowire Uniformity

- Why is a precision laboratory hydraulic press required for sulfide-based batteries? Achieve Critical Ion Conductivity

- What is the sealing pipe requirement for inlet pressure in water circulating vacuum pumps? Ensure System Integrity Above 0.03 MPa

- What is the point of a vacuum chamber? Achieve Absolute Control in Your Processes

- What are the different grades of Alumina ceramic and how do they differ? Choose the Right Grade for Your Needs

- What type of pump is used in water circulating vacuum pumps and how is it installed? Discover Robust Fluid-Based Vacuum Solutions

- Why is an alumina crucible required for bauxite residue thermal analysis? Ensure Stability and Data Purity Up to 1400°C

- What are the structural functions of the dual-chamber quartz glass container? Optimize Magnesium Alloy Vapor Analysis