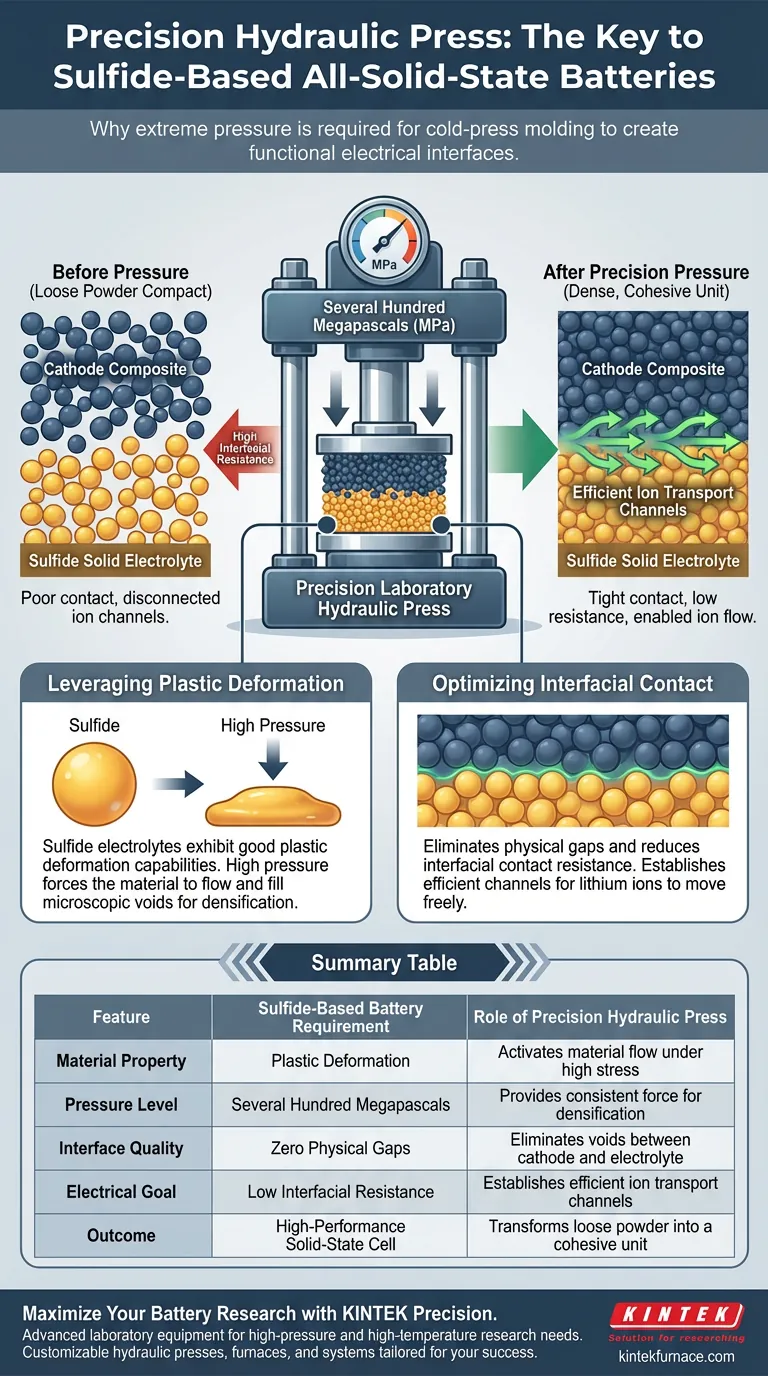

A precision laboratory hydraulic press is required because sulfide-based solid-state batteries rely on extreme pressure to create functional electrical interfaces. Unlike liquid electrolytes that naturally wet surfaces, sulfide electrolytes must be mechanically forced into shape. By applying pressures of several hundred megapascals, the press exploits the material's plastic deformation capabilities to fuse the cathode composite and solid electrolyte into a single, cohesive unit.

The performance of a sulfide-based battery is dictated by the quality of the contact between its layers. Without the high pressure of a hydraulic press to induce plastic deformation, you cannot minimize interfacial resistance or establish the necessary channels for ion transport.

Leveraging Plastic Deformation

The Unique Property of Sulfide Electrolytes

Sulfide electrolytes are chemically distinct because they exhibit good plastic deformation capabilities. This means the material can change shape permanently under stress without breaking.

The Necessity of High Pressure

To activate this property, significant force is required. A laboratory hydraulic press is essential because it can consistently generate pressures of several hundred megapascals.

Molding the Composite

This pressure is not merely for shaping; it is for densification. The press forces the solid material to flow and fill microscopic voids, creating a dense pellet rather than a loose powder compact.

Optimizing Interfacial Contact

Eliminating Physical Gaps

The primary function of the cold-pressing process is to ensure tight physical contact. This must be achieved specifically between the cathode composite and the solid electrolyte layer.

Reducing Contact Resistance

Any gap between these layers acts as a barrier to energy flow. By eliminating these gaps through high-pressure molding, you significantly reduce interfacial contact resistance.

Enabling Ion Flow

Low resistance is a prerequisite for battery function. The tight contact allows for the establishment of efficient ion transport channels, allowing lithium ions to move freely between the cathode and the electrolyte.

Understanding the Trade-offs

The Risk of Insufficient Pressure

If a press cannot achieve the required hundreds of megapascals, the sulfide material will not deform sufficiently. This results in poor physical contact and high internal resistance.

The Consequence of Poor Molding

Without sufficient cold-pressing, the ion transport channels will remain disconnected. This renders the battery inefficient or entirely non-functional, regardless of the chemical quality of the materials used.

Making the Right Choice for Your Goal

To maximize the performance of sulfide-based all-solid-state batteries, apply the following principles:

- If your primary focus is minimizing resistance: Ensure your hydraulic press can sustain pressures of several hundred megapascals to fully densify the interface.

- If your primary focus is material efficiency: Rely on the plastic deformation properties of sulfides to create tight contact without the need for high-temperature sintering.

The hydraulic press is not just a manufacturing tool; it is the critical enabler of ion transport in solid-state chemistry.

Summary Table:

| Feature | Sulfide-Based Battery Requirement | Role of Precision Hydraulic Press |

|---|---|---|

| Material Property | Plastic Deformation | Activates material flow under high stress |

| Pressure Level | Several Hundred Megapascals | Provides consistent force for densification |

| Interface Quality | Zero Physical Gaps | Eliminates voids between cathode and electrolyte |

| Electrical Goal | Low Interfacial Resistance | Establishes efficient ion transport channels |

| Outcome | High-Performance Solid-State Cell | Transforms loose powder into a cohesive unit |

Maximize Your Battery Research with KINTEK Precision

High-performance sulfide-based all-solid-state batteries demand more than just chemistry—they require mechanical precision. KINTEK provides the advanced laboratory equipment necessary to bridge the gap between material potential and functional performance.

Backed by expert R&D and manufacturing, KINTEK offers customizable hydraulic presses, Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique high-pressure and high-temperature research needs. Whether you are minimizing interfacial resistance or optimizing material densification, our tools ensure your research is supported by the highest standards of reliability.

Ready to elevate your lab's capabilities? Contact us today to discuss your custom furnace or press requirements!

Visual Guide

References

- Leonhard Karger, Torsten Brezesinski. Protective Nanosheet Coatings for Thiophosphate‐Based All‐Solid‐State Batteries. DOI: 10.1002/admi.202301067

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What roles do metal shielding disks and heat shields play in in-situ SEM? Ensure Precision & Protect Your Lab Equipment

- Why are precision filters and ice baths used in pyrolysis? Protect Your Data and Lab Equipment

- What are the advantages of using high-purity alumina crucibles? Achieve Precise Cast Iron Phase Equilibrium Data

- What is the function of a vacuum drying oven for biochar FTIR analysis? Ensure High-Purity Sample Preparation

- What are the technical functions of condensation units and gas collection bags? Optimize Your Reduction Experiments

- What are the functions of a high vacuum mechanical pump in Ga2O3 PETO? Ensure Purity in Film Preparation

- What are the functions of a tungsten wire basket and a quartz crucible? Enhancing Purity in Vacuum Evaporation

- What factors influence the lifespan of alumina ceramic furnace tubes? Maximize Durability and Performance