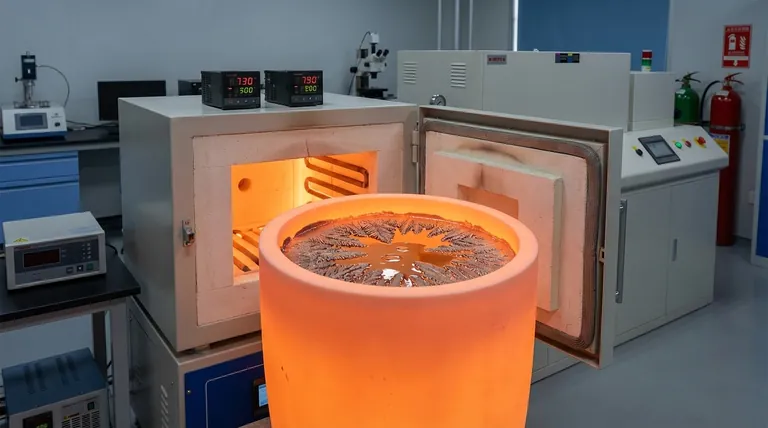

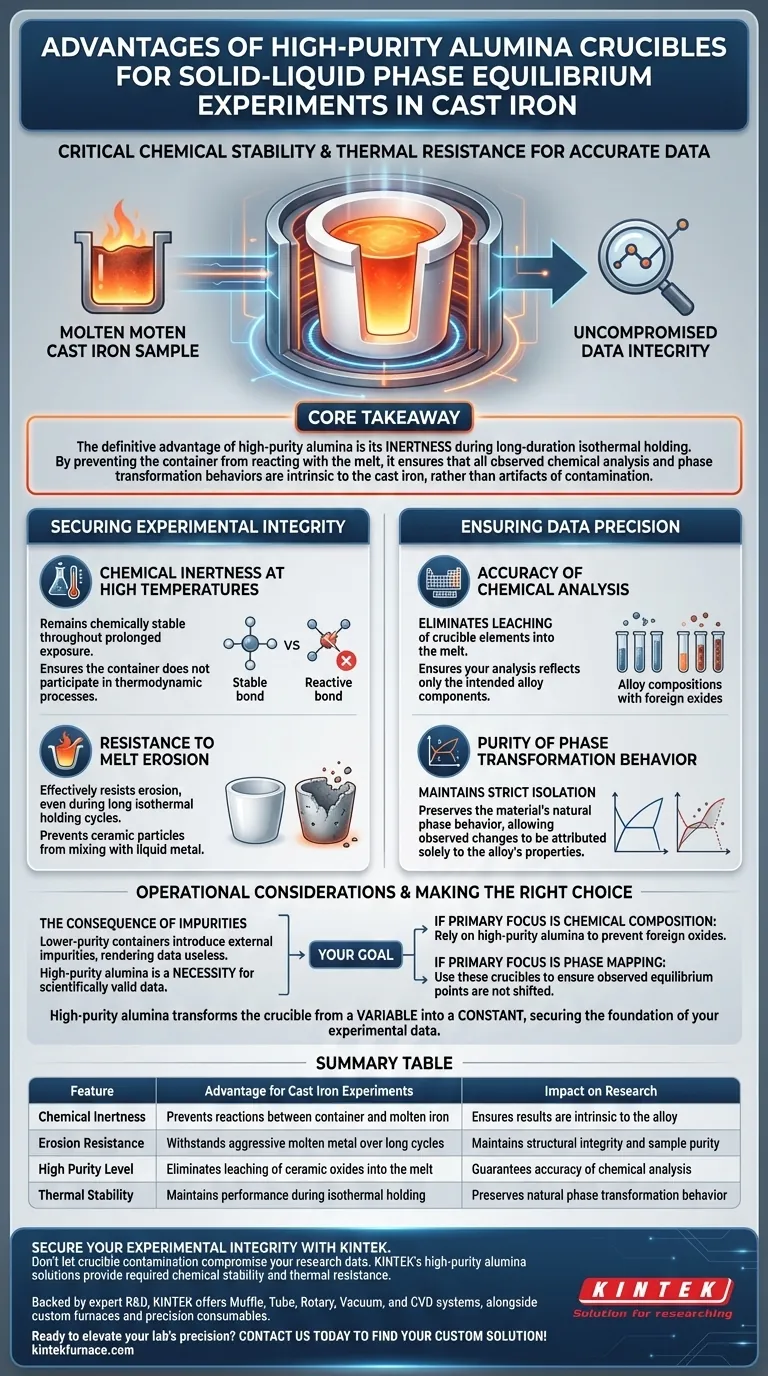

High-purity alumina crucibles provide the critical chemical stability and thermal resistance required for accurate solid-liquid phase equilibrium experiments. They are specifically designed to resist erosion during prolonged contact with molten cast iron, preventing the crucible material from contaminating the alloy and compromising your data.

Core Takeaway The definitive advantage of high-purity alumina is its inertness during long-duration isothermal holding. By preventing the container from reacting with the melt, it ensures that all observed chemical analysis and phase transformation behaviors are intrinsic to the cast iron, rather than artifacts of contamination.

Securing Experimental Integrity

Chemical Inertness at High Temperatures

Solid-liquid phase equilibrium experiments often require maintaining molten cast iron at specific temperatures for extended periods. High-purity alumina remains chemically stable throughout this prolonged exposure.

This stability creates a reliable reaction space. It ensures that the container itself does not participate in the thermodynamic processes you are attempting to measure.

Resistance to Melt Erosion

Molten cast iron is aggressive and can erode standard containment materials over time. High-purity alumina effectively resists this erosion, even during long isothermal holding cycles.

By maintaining its structural integrity, the crucible prevents physical degradation. This eliminates the risk of ceramic particles sloughing off and mechanically mixing with the liquid metal.

Ensuring Data Precision

Accuracy of Chemical Analysis

The primary goal of equilibrium experiments is to analyze specific alloy compositions. Prevents leaching of crucible elements into the melt is non-negotiable for valid results.

If a crucible degrades, it introduces oxides or other impurities into the cast iron. High-purity alumina eliminates this variable, ensuring your chemical analysis reflects only the intended alloy components.

Purity of Phase Transformation Behavior

Phase transformation data is highly sensitive to impurities. External contaminants can alter the solidification path, changing the freezing range or the nature of the phases formed.

By maintaining strict isolation between the melt and the container, high-purity alumina preserves the material's natural phase behavior. This allows researchers to attribute observed changes solely to the alloy's properties, not to experimental error.

Operational Considerations

The Consequence of Impurities

While standard ceramic crucibles are useful for general applications, they often fail under the specific demands of equilibrium studies. The use of lower-purity containers introduces external impurities during the heating and holding cycles.

In the context of phase equilibrium, even minor contamination renders the data useless. The "advantage" of high-purity alumina is, therefore, better understood as a necessity: it is the baseline requirement for generating scientifically valid data in this specific field.

Making the Right Choice for Your Goal

To maximize the validity of your cast iron experiments, align your equipment choice with your specific analytical needs:

- If your primary focus is Chemical Composition: Rely on high-purity alumina to prevent the introduction of foreign oxides that would skew elemental analysis.

- If your primary focus is Phase Mapping: Use these crucibles to ensure that observed equilibrium points are not shifted by dissolved crucible material.

High-purity alumina transforms the crucible from a variable into a constant, securing the foundation of your experimental data.

Summary Table:

| Feature | Advantage for Cast Iron Experiments | Impact on Research |

|---|---|---|

| Chemical Inertness | Prevents reactions between container and molten iron | Ensures results are intrinsic to the alloy |

| Erosion Resistance | Withstands aggressive molten metal over long cycles | Maintains structural integrity and sample purity |

| High Purity Level | Eliminates leaching of ceramic oxides into the melt | Guarantees accuracy of chemical analysis |

| Thermal Stability | Maintains performance during isothermal holding | Preserves natural phase transformation behavior |

Secure Your Experimental Integrity with KINTEK

Don't let crucible contamination compromise your research data. KINTEK’s high-purity alumina solutions provide the chemical stability and thermal resistance required for the most demanding solid-liquid phase equilibrium studies.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable high-temperature lab furnaces and precision consumables designed for your unique needs.

Ready to elevate your lab's precision? Contact us today to find your custom solution!

Visual Guide

References

- Ricardo Queirós, Attila Diószegi. Assessing Pore Formation due to Nitrogen Partitioning in a Hypoeutectic Cast Iron. DOI: 10.1007/s40962-024-01521-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the necessity of a cylindrical condenser in a microwave-assisted metal reduction system? Key Protection Insights

- What role does a high-purity alumina crucible play in BSO synthesis? Ensure Purity in High-Temperature Reactions

- What are the functions of silicon nitride ceramic sample holders? Precision for High-Temperature Levitation

- What is the technical significance of using a quartz boat in 2D superlattice preparation? Enhancing CVD Precision

- What role do refractory bricks and graphite paper play within a quartz tube? Optimize RuMoOx/NC Synthesis Efficiency

- Why is a heat-resistant crucible indispensable for magnesium purification? Ensuring Purity and Efficiency in Vacuum Sublimation

- Why is a high-purity graphite box required for CZTS sulfurization? Protect Thin Film Integrity and Crystallinity

- What is the key technological improvement in the circulating water vacuum pump? Discover the Self-Contained Closed-Loop System