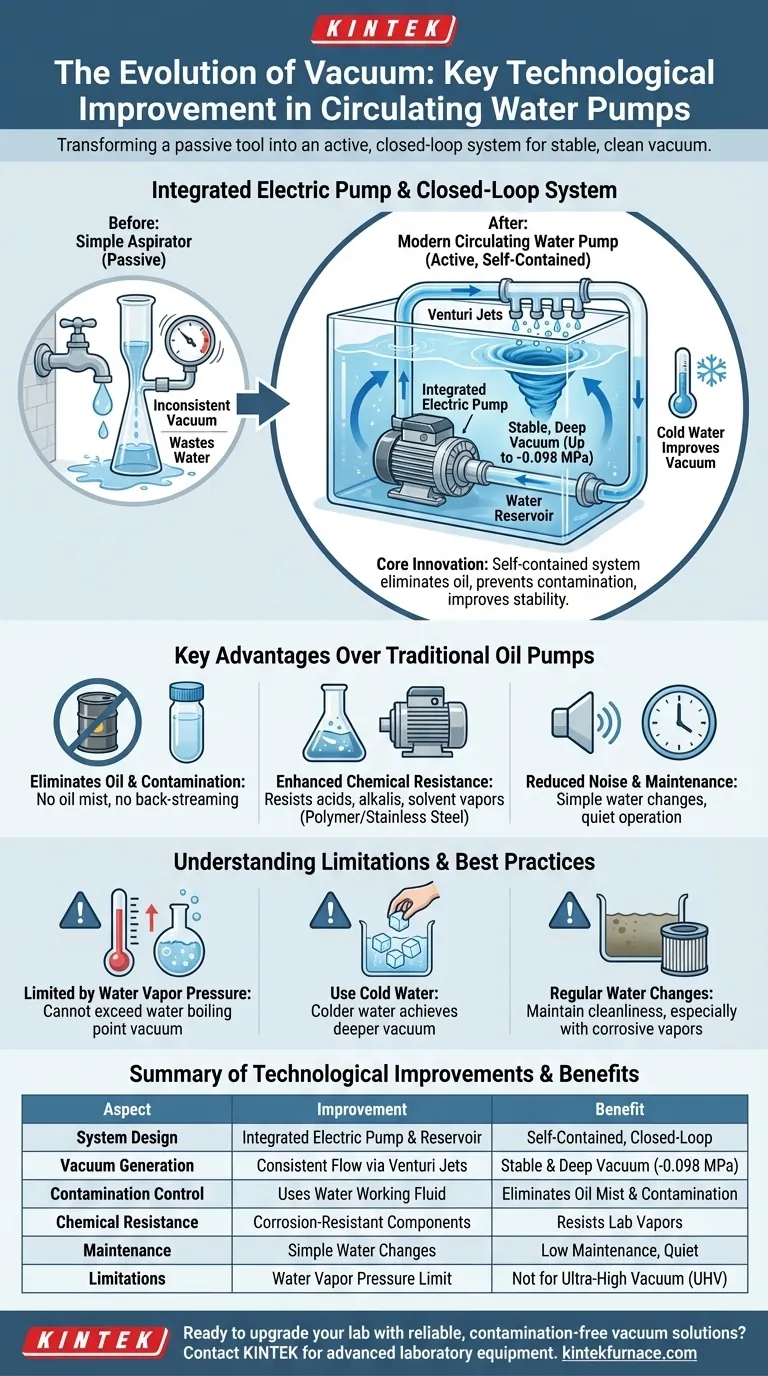

At its core, the key technological improvement in the circulating water vacuum pump is the integration of a dedicated, self-contained freshwater pump into what was originally a simple glass apparatus. This innovation transforms the device from a passive tool dependent on external water pressure into an active, closed-loop system. By using its own pump to cycle water, it generates a consistent, stable, and efficient vacuum independent of any external plumbing.

The core innovation wasn't just adding a water pump; it was creating a self-contained, closed-loop system. This fundamental shift eliminates the need for oil, prevents sample contamination, and dramatically improves vacuum stability, making it a reliable and clean workhorse for modern laboratories.

From Simple Aspirator to Integrated System

To grasp the significance of this improvement, it's helpful to understand the evolution from the original concept to the modern device.

The Original Principle: The Venturi Effect

Early water "pumps" were often simple glass or metal aspirators attached directly to a laboratory faucet. They work on the Venturi effect, where a fast-moving stream of water creates a low-pressure zone, pulling air or gas from the connected apparatus.

The primary drawback of this design was its inconsistency. The vacuum level was entirely dependent on the building's water pressure, which could fluctuate wildly, leading to unstable experiments. It also wasted a tremendous amount of water.

The Core Innovation: The Integrated Electric Pump

The modern circulating water vacuum pump solves these problems by incorporating an electric water pump and a water reservoir (tank) into a single unit.

Instead of relying on tap pressure, the internal pump creates a powerful and consistent flow of water from its own tank. This water circulates through one or more venturi jets, generating a stable and deep vacuum. The water then returns to the tank to be reused.

The Result: Stable and Deep Vacuum

This closed-loop design provides a consistent water flow rate and pressure, resulting in a stable and reproducible vacuum. High-quality models can achieve an ultimate vacuum level around -0.098 MPa (2 kPa), far more reliable than a simple faucet aspirator.

Key Advantages Over Traditional Oil Pumps

The circulating water vacuum pump's design gives it several critical advantages over older, oil-sealed rotary vane pumps.

Eliminating Oil and Contamination

The most significant benefit is that it uses water, not oil, as its working fluid. This completely eliminates the risk of oil mist contaminating the laboratory air or, more critically, back-streaming into and ruining a sensitive sample.

Enhanced Chemical Resistance

Many models are built with polymer or stainless steel components specifically designed to be resistant to acids, alkalis, and solvent vapors. While pumping corrosive gas requires more frequent water changes, the pump itself is far less susceptible to damage than an oil pump, whose oil would quickly become contaminated and lose effectiveness.

Reduced Noise and Maintenance

These pumps are remarkably quiet, often featuring specialized fluid mufflers. Maintenance is simple: periodically change the water in the tank. This is a stark contrast to oil pumps, which require messy oil changes, decontamination, and management of waste oil.

Understanding the Trade-offs and Limitations

While highly effective, it's crucial to understand the operational realities of these pumps to use them correctly.

The Limit of Water's Vapor Pressure

The deepest vacuum a water pump can achieve is fundamentally limited by the vapor pressure of water. As the pressure in the system drops, the water itself will begin to boil, and the pump cannot pull a vacuum lower than that vapor pressure.

This is why it is critical to use cold water in the reservoir. Colder water has a much lower vapor pressure, allowing the pump to achieve a deeper vacuum.

The Importance of Water Cleanliness

The water in the reservoir must be kept clean. Debris can clog the pump's jets, and dissolved contaminants from the evacuated system can degrade pump performance. When pumping corrosive vapors, this water should be changed very frequently.

Not Suitable for Ultra-High Vacuum

Circulating water pumps are ideal for rough to medium vacuum applications like rotary evaporation, filtration, and degassing. They are not designed for high-vacuum or ultra-high vacuum (UHV) applications, which require more advanced technologies like turbomolecular or ion pumps.

Making the Right Choice for Your Application

Selecting and using your pump correctly hinges on understanding your primary goal.

- If your primary focus is general laboratory work (e.g., rotary evaporation, filtration): A circulating water vacuum pump is an ideal, cost-effective, and low-maintenance choice that eliminates oil contamination risk.

- If your primary focus is working with corrosive vapors: Choose a model with a corrosion-resistant body and be prepared to change the water frequently to maintain performance and pump longevity.

- If your primary focus is achieving the deepest possible vacuum: Always start with fresh, cold water in the reservoir, as this directly impacts the pump's ultimate vacuum level.

By understanding its principles, you can leverage this simple yet powerful tool to achieve clean and reliable vacuum for a wide range of scientific tasks.

Summary Table:

| Aspect | Key Technological Improvement | Benefits |

|---|---|---|

| System Design | Integrated electric pump and water reservoir | Creates a self-contained, closed-loop system |

| Vacuum Generation | Consistent water flow via venturi jets | Provides stable and deep vacuum (up to -0.098 MPa) |

| Contamination Control | Uses water instead of oil | Eliminates oil mist and sample contamination |

| Chemical Resistance | Polymer or stainless steel components | Resists acids, alkalis, and solvent vapors |

| Maintenance | Simple water changes | Reduces noise and maintenance compared to oil pumps |

| Limitations | Limited by water vapor pressure | Not suitable for ultra-high vacuum applications |

Ready to upgrade your lab with reliable, contamination-free vacuum solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you need stable vacuum systems or tailored thermal processing equipment.

Contact us today to discuss how our innovative products can enhance your lab's efficiency and reliability—Get in touch now!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the technical objective of using vacuum-sealed quartz capsules for Co-Ti-V alloy homogenization? Safeguard Chemical Integrity

- Why are micrometer-scale micro-fiber filter candles used to treat condensed flue gases in pyrolysis systems?

- How is measurement accuracy maintained for infrared pyrometers? Master Optical Hygiene for High-Temp Metallic Melts

- What is the role of providing a uniform heating environment? Achieve Perfect Deep Eutectic Solvent Formation

- What is the primary purpose of using a high-purity quartz vacuum ampule? Unlock High-Quality WSe2 Crystal Growth

- Why are ceramic crucibles required for the high-temperature calcination of dolomite? Ensure High-Purity Results

- How does a laboratory drying oven ensure the structural stability of microcapsule granules? Expert Drying Guide

- Why is a rotary evaporator used to process separated fractions in hydrotreated coal tar analysis? Enhance Sample Purity