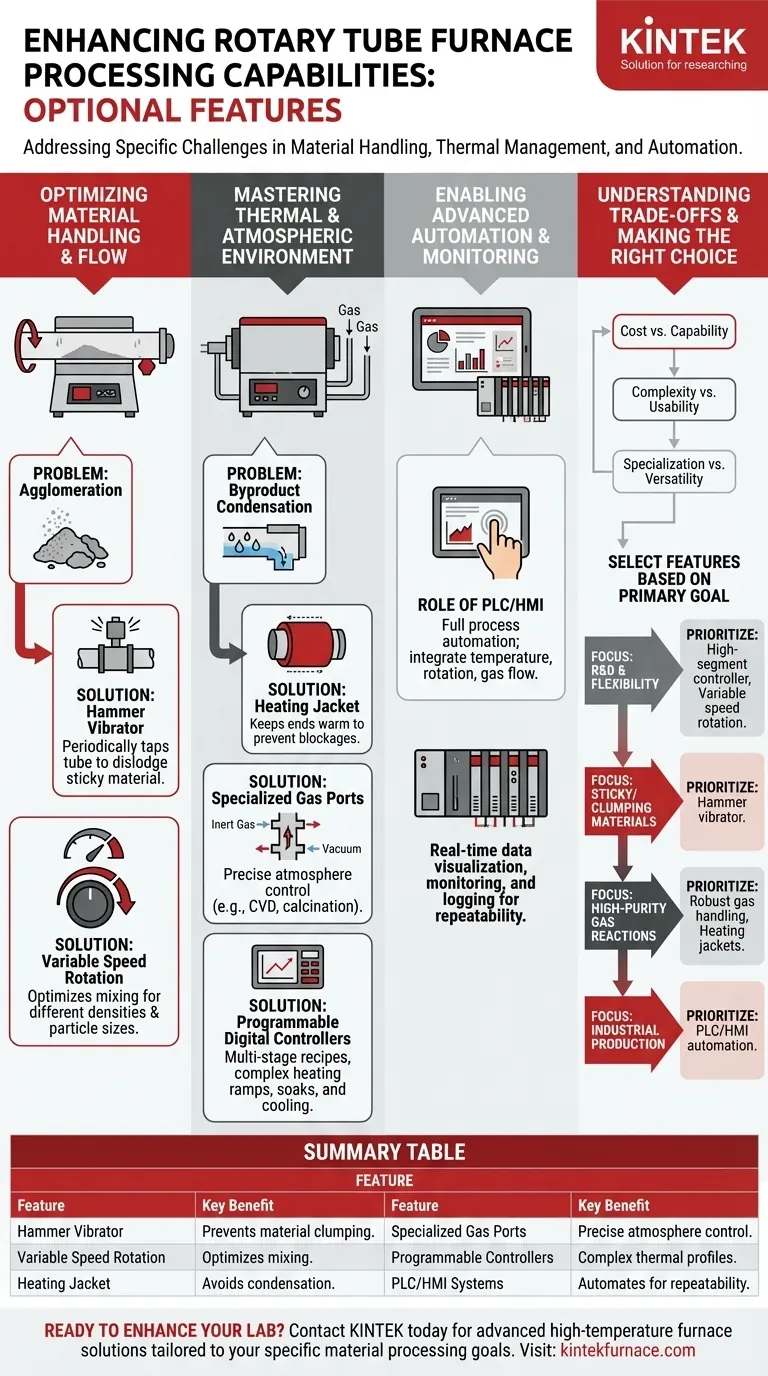

Optional features for rotary tube furnaces are designed to move beyond simple heating and address specific challenges in material handling, thermal management, and process automation. Key enhancements include hammer vibrators to agitate sticky materials, specialized gas ports for precise atmosphere control, heating jackets to prevent byproduct condensation, and advanced PLC systems for fully automated and repeatable operation.

A standard rotary tube furnace provides uniform heating by rotating material. The true value of optional features lies in their ability to solve specific processing challenges—such as material flow, gas reactions, and process repeatability—transforming a simple heater into a highly specialized processing instrument.

Optimizing Material Handling and Flow

The core function of a rotary furnace is to tumble and mix loose materials. However, certain materials present unique flow challenges that standard rotation cannot solve alone.

The Problem of Material Agglomeration

Many powders, especially those with high viscosity or a tendency to become sticky at high temperatures, can clump, agglomerate, or cake to the tube wall. This leads to non-uniform heating and poor process results.

Solution: Mechanical Agitation

For materials prone to clumping, a hammer vibrator is a critical addition. This device periodically taps or vibrates the tube, mechanically dislodging material that is sticking to the walls or forming clumps, ensuring everything remains free-flowing.

Solution: Variable Speed Rotation

A variable speed rotation system provides precise control over the tumbling action. Adjusting the rotational speed allows you to optimize mixing for different material densities, particle sizes, and flow characteristics, ensuring optimal residence time and heat exposure.

Mastering the Thermal and Atmospheric Environment

Advanced material processing often requires more than just a stable temperature. The entire thermal profile and gaseous environment must be precisely managed.

Preventing Unwanted Byproduct Condensation

In processes like pyrolysis, decomposition can release tars or other volatile organic compounds. These can condense in the cooler outlet sections of the furnace, causing blockages and contaminating the system.

A heating jacket installed on the ends of the process tube keeps these areas warm, preventing condensation and ensuring reaction byproducts are properly exhausted from the system.

Achieving Precise Atmosphere Control

Applications like Chemical Vapor Deposition (CVD) or calcination under an inert atmosphere require a pure, controlled gas environment.

For this, furnaces can be equipped with specialized gas handling ports. These typically include dedicated inert gas inlets (e.g., 1/4 inch ports) and larger outgassing ports (e.g., KF25) for efficient vacuum purging and removal of reaction gases.

Customizing Thermal Profiles

Many processes require complex, multi-stage temperature cycles. Standard controllers may not be sufficient.

Programmable digital controllers are an essential feature for this, allowing operators to program multi-segment recipes. For example, a controller with 30 total segments enables intricate profiles of heating ramps, temperature soaks, and controlled cooling steps.

Enabling Advanced Automation and Monitoring

For industrial-scale production or processes requiring high repeatability, manual control is inefficient and introduces variability.

The Role of PLCs and HMIs

Programmable Logic Controllers (PLCs) paired with Human-Machine Interfaces (HMIs) enable full process automation. These systems integrate control over temperature, rotation speed, gas flow, and vibration.

An operator can load a pre-set recipe, and the PLC will execute the entire process automatically. The HMI provides real-time data visualization, monitoring, and logging, which is critical for quality control and process repeatability.

Understanding the Trade-offs

Adding features enhances capability but also introduces complexities and costs that must be weighed carefully.

Cost vs. Capability

Every optional feature adds to the initial capital cost of the furnace. It is vital to select only the features that solve a demonstrated or highly anticipated process problem, avoiding unnecessary expense.

Complexity vs. Usability

A fully-featured furnace with a PLC, vibrator, and custom gas handling is a more complex piece of equipment. It may require specialized knowledge for programming and will have more components that require maintenance or can potentially fail.

Specialization vs. Versatility

Highly specific customizations, such as a work tube with a unique internal shape for one particular powder, can make the furnace less suitable for general-purpose use. This is a key consideration in a multi-purpose lab versus a dedicated production line.

Making the Right Choice for Your Goal

Select features based on the primary challenge you need to solve.

- If your primary focus is R&D and process flexibility: Prioritize a high-segment programmable controller and variable speed rotation to explore a wide range of materials and thermal profiles.

- If your primary focus is processing sticky or clumping materials: A hammer vibrator is non-negotiable for ensuring consistent material flow and uniform heating.

- If your primary focus is high-purity gas reactions (e.g., CVD): Insist on a robust gas handling system with dedicated ports and consider heating jackets to prevent byproduct contamination.

- If your primary focus is industrial production and repeatability: A PLC/HMI automation system is the key to achieving consistent quality, reducing labor, and enabling process data logging.

Ultimately, selecting the right features transforms the furnace from a generic tool into a precise solution tailored to your specific material processing goals.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Hammer Vibrator | Prevents material clumping for uniform heating |

| Variable Speed Rotation | Optimizes mixing for different materials |

| Heating Jacket | Avoids condensation and blockages |

| Specialized Gas Ports | Enables precise atmosphere control |

| Programmable Digital Controllers | Allows complex thermal profiles |

| PLC/HMI Systems | Automates processes for repeatability |

Ready to enhance your lab's capabilities with a customized rotary tube furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can tailor a solution for your specific material processing goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control