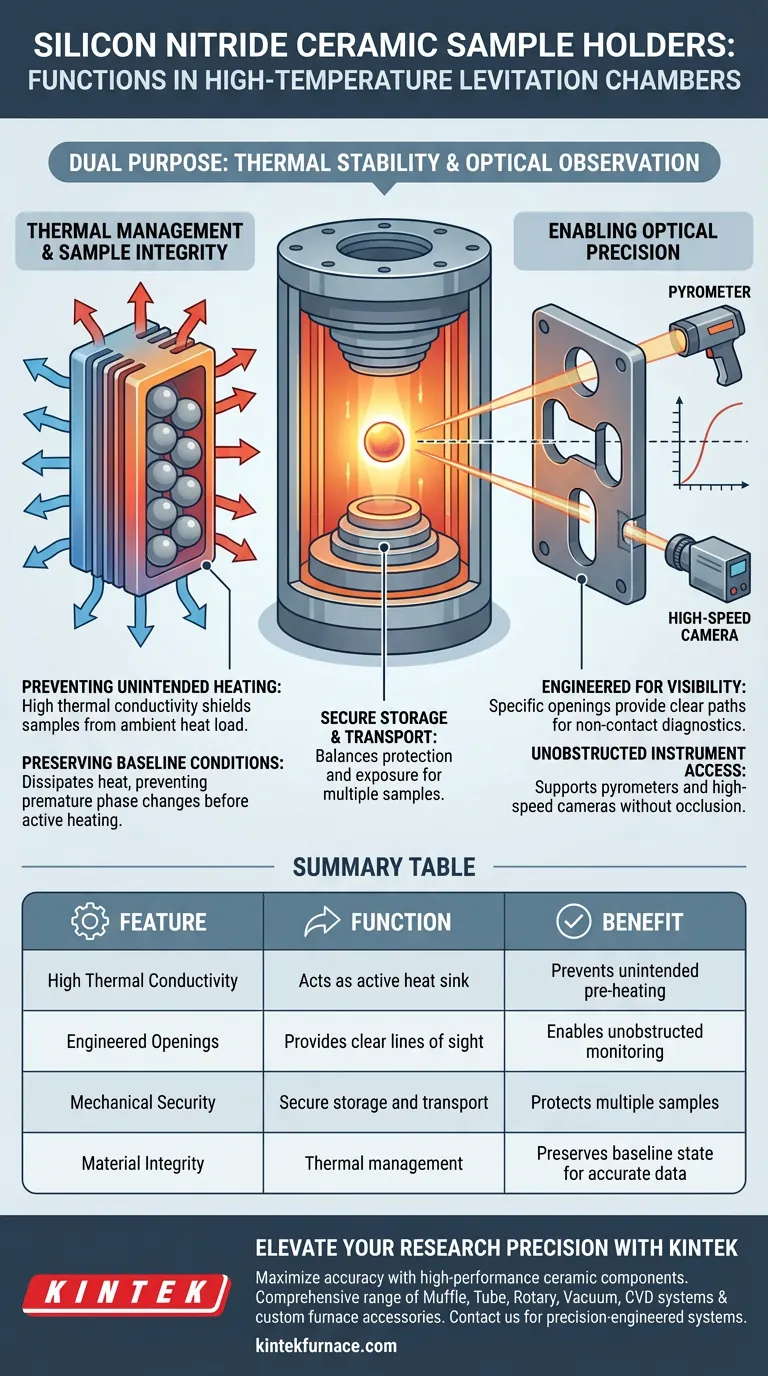

Silicon nitride ceramic sample holders serve a dual purpose within high-temperature levitation chambers: ensuring the thermal stability of stored materials and facilitating precise optical observation. They function as secure, thermally conductive storage units that protect samples from premature heating while providing clear lines of sight for critical measurement instruments.

By leveraging high thermal conductivity, these holders act as active thermal management tools rather than passive containers. They preserve the sample's initial state by dissipating heat, preventing data contamination caused by unintentional pre-heating before the experiment begins.

Thermal Management and Sample Integrity

Preventing Unintended Heating

High-temperature levitation chambers create a thermally aggressive environment. The primary technical function of the holder is to shield stored samples from this ambient heat load before the active experiment begins.

The Role of High Thermal Conductivity

Silicon nitride is selected specifically for its high thermal conductivity. This property allows the holder to act as an effective heat sink, rapidly drawing heat away from the samples it contains.

Preserving Baseline Conditions

By dissipating heat, the holder ensures samples do not undergo unintended temperature increases. This is critical for preventing premature phase changes or structural alterations before the active heating phase initiates.

Enabling Optical Precision

Engineered for Visibility

Levitation experiments rely heavily on non-contact diagnostics. To support this, the sample holders are engineered with specific opening designs rather than being fully enclosed.

Unobstructed Instrument Access

These openings provide a clear, unobstructed path for optical devices. This design ensures that the physical structure of the holder does not interfere with the line of sight required for data collection.

Supporting Pyrometers and High-Speed Cameras

The specific geometry allows instruments such as pyrometers (for temperature measurement) and high-speed cameras (for dynamic observation) to view the levitated samples without occlusion.

Operational Considerations and Trade-offs

Secure Storage and Transport

Beyond thermal and optical properties, the holders must mechanically secure multiple samples. This allows for the transport and storage of several experimental candidates simultaneously within the chamber.

Balancing Protection and Exposure

The design represents a trade-off between shielding and visibility. The holder must be substantial enough to act as a heat sink and secure the sample, yet open enough to allow for sophisticated optical monitoring.

Optimizing Experimental Setup

To maximize the utility of silicon nitride holders in your high-temperature experiments, consider your specific diagnostic needs:

- If your primary focus is material purity: Rely on the holder's high thermal conductivity to maintain a stable, cool baseline temperature for your samples prior to levitation.

- If your primary focus is data acquisition: Ensure the holder's specific opening design aligns perfectly with the viewing angles of your pyrometers and imaging systems to prevent data gaps.

Effective use of these holders ensures that your samples enter the levitation phase in a controlled, pristine state, ready for accurate measurement.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| High Thermal Conductivity | Acts as an active heat sink | Prevents unintended pre-heating and premature phase changes. |

| Engineered Openings | Provides clear lines of sight | Enables unobstructed monitoring by pyrometers and high-speed cameras. |

| Mechanical Security | Secure storage and transport | Protects multiple samples and facilitates handling within the chamber. |

| Material Integrity | Thermal management | Preserves the sample's baseline state for accurate data collection. |

Elevate Your Research Precision with KINTEK

Maximize your experimental accuracy with high-performance ceramic components tailored for extreme environments. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature furnace accessories designed to meet your unique research needs.

Ready to optimize your thermal management and data acquisition? Contact KINTEK today to discover how our precision-engineered systems can support your next breakthrough.

Visual Guide

References

- G. Lohöfer, Andreas Meyer. TEMPUS—A microgravity electromagnetic levitation facility for parabolic flights. DOI: 10.1063/5.0182719

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of a laboratory drying oven in SnO2 film pre-treatment? Ensure Crack-Free Film Stabilization

- Why are high-purity alumina tubes and crucibles preferred for high-temperature smelting? Ensure Maximum Sample Purity

- What temperature range can graphite crucible furnaces withstand? Achieve Extreme Heat for High-Melting Metals

- Why is a high-purity quartz boat selected for Tellurium purification? Achieve 5N+ Semiconductor Grade Results

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications

- What are the benefits of the improved circulating water vacuum pump? Save Costs and Go Green in Your Lab

- How does the circulating water multifunctional vacuum pump create a vacuum? Discover Its Oil-Free Mechanism

- Why is a molybdenum crucible considered an ideal choice for quartz melting? High-Purity Solutions at 2000°C