At its core, a circulating water vacuum pump creates a vacuum by using a rapidly rotating impeller to form a ring of water inside a pump casing. Because the impeller is offset (eccentric), the space between its blades and the water ring constantly changes, first expanding to suck in gas and then contracting to compress and expel it. This continuous cycle of suction and compression is what lowers the pressure and generates the vacuum.

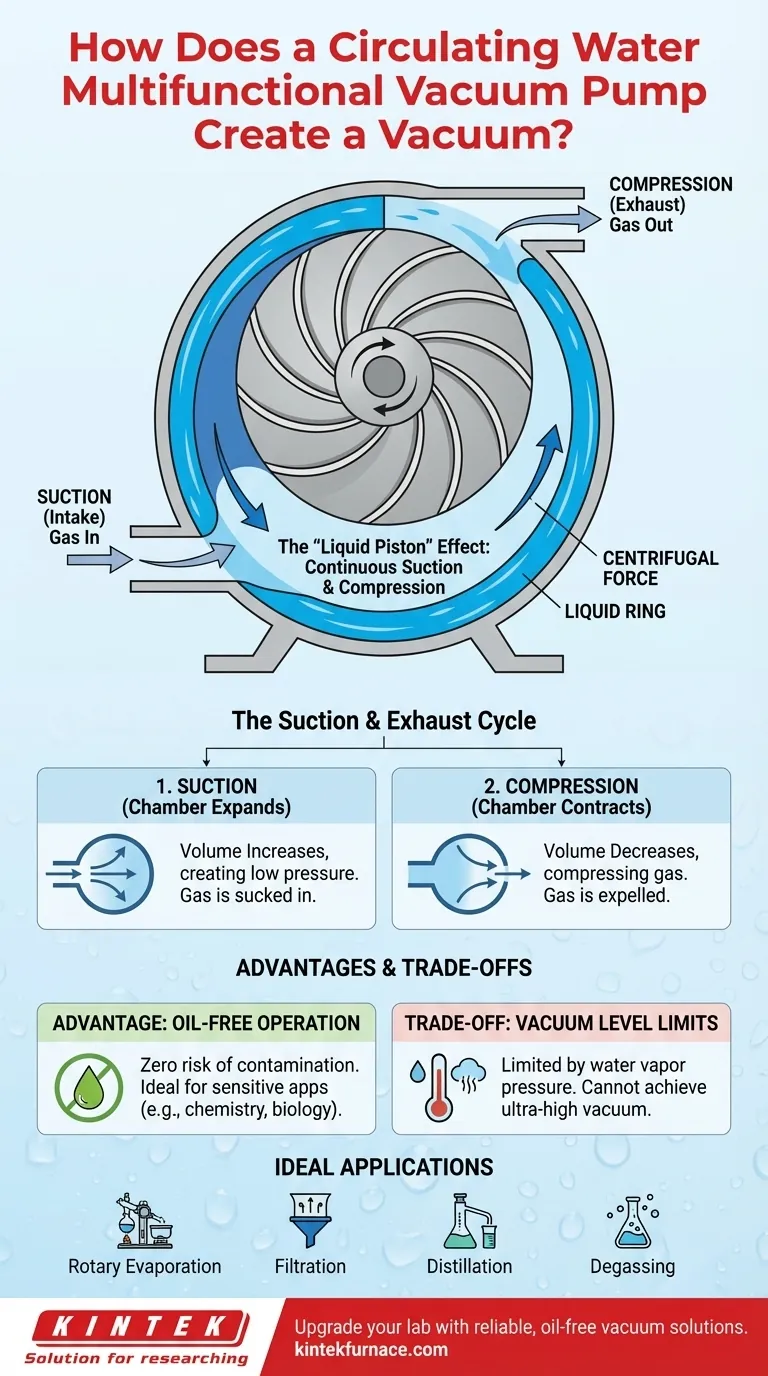

The pump doesn't suck air directly. Instead, it uses centrifugal force to turn its water supply into a dynamic, liquid piston. The changing volume of the chambers created by this "piston" is what draws in and removes gas from a system.

The Core Mechanism: From Water to Vacuum

To understand how this pump works, we need to follow the journey of the water inside it. The entire process is a clever application of fluid dynamics and mechanical design.

The Role of the Working Fluid

The pump is filled with a working fluid, which is typically just water. This is a key design feature, as the water serves as both the sealing and compressing medium, eliminating the need for oil.

Creating the Liquid Ring

When the pump is turned on, a motor drives an impeller with multiple blades. As the impeller spins at high speed, centrifugal force throws the water outward against the inner wall of the cylindrical pump casing, forming a consistent, rotating ring of liquid.

The 'Liquid Piston' in Action

Crucially, the impeller is mounted eccentrically (off-center) within the casing. The inner surface of the water ring is concentric with the casing, but the impeller is not.

This offset means that as the impeller blades rotate, the space between the hub of the impeller and the inner surface of the water ring continuously changes. This creates a series of small, crescent-shaped chambers that expand and contract with each rotation. This dynamic is often called a "liquid piston."

The Suction and Exhaust Cycle

The process of creating a vacuum happens in two distinct phases during each rotation:

- Suction (Intake): As a chamber between two blades rotates past the inlet port, the volume of that chamber increases. This expansion creates a zone of low pressure (negative pressure), which sucks gas in from the system you want to evacuate.

- Compression (Exhaust): As that same chamber continues its rotation, the eccentric design forces it to shrink in volume. This compresses the captured gas. Once the pressure is high enough, the gas (along with a small amount of water vapor) is forced out through the exhaust port.

This cycle repeats rapidly for every chamber between the blades, resulting in a continuous and smooth pumping action that steadily reduces the pressure in the connected vessel.

Understanding the Advantages and Trade-offs

While effective, this design has specific benefits and limitations that make it suitable for some applications but not others.

Key Advantage: Oil-Free Operation

The most significant benefit is that the pump is oil-free. Since water is the only sealing and lubricating fluid, there is zero risk of oil vapor contaminating your experiment or product. This makes it ideal for sensitive applications in chemistry, biology, and pharmaceuticals. It also results in lower noise and simpler maintenance.

Trade-off: Vacuum Level Limitations

The ultimate vacuum this pump can achieve is limited by the vapor pressure of the water being used. As the pressure in the system drops, the water itself will begin to boil (evaporate). This water vapor enters the vacuum, and the pump cannot lower the pressure below this point. The vacuum level is therefore temperature-dependent, as warmer water has a higher vapor pressure.

Trade-off: Water Consumption and Quality

The circulating water absorbs heat generated during gas compression. Over time, this water will warm up, reducing pump efficiency. In some setups, fresh cold water is continuously supplied to maintain performance. Furthermore, if the pump is used to evacuate corrosive or reactive gases, these can dissolve in the water, requiring its eventual treatment and disposal.

Making the Right Choice for Your Application

Choosing a pump requires matching its capabilities to your specific goal.

- If your primary focus is on routine lab processes: For applications like rotary evaporation, filtration, distillation, and degassing, the circulating water vacuum pump is an excellent, cost-effective, and clean choice.

- If your primary focus is achieving high or ultra-high vacuum: For processes like mass spectrometry or surface science experiments that require pressures far below the vapor pressure of water, this pump is unsuitable. You will need to consider multi-stage, oil-based, or dry scroll pumps instead.

Ultimately, the circulating water vacuum pump is a reliable workhorse for general-purpose vacuum needs where cleanliness and simplicity are paramount.

Summary Table:

| Aspect | Details |

|---|---|

| Core Mechanism | Uses a rotating impeller to form a water ring, creating chambers that expand and contract to suck in and expel gas. |

| Key Advantage | Oil-free operation, preventing contamination in sensitive applications like chemistry and biology. |

| Vacuum Limitation | Limited by water vapor pressure; cannot achieve ultra-high vacuum levels. |

| Ideal Applications | Rotary evaporation, filtration, distillation, and degassing where cleanliness is crucial. |

Upgrade your lab with reliable, oil-free vacuum solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces and vacuum systems tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. If you're involved in chemistry, biology, or pharmaceuticals and need clean, efficient vacuum technology, contact us today to discuss how we can enhance your processes and deliver superior performance!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a sintering process using a lab furnace necessary for Li6PS5Cl disks? Enhance Conductivity & Density

- What is the function of graphite molds in the Spark Plasma Sintering (SPS) of high-entropy alloys?

- How does a nitrogen nozzle system influence the quality of components? Optimize Cooling for Structural Integrity

- Why is a heat-resistant crucible indispensable for magnesium purification? Ensuring Purity and Efficiency in Vacuum Sublimation

- How does Energy Dispersive X-ray Spectroscopy (EDX) assist in adjusting furnace parameters? Biochar Quality Control

- What are the technical functions of condensation units and gas collection bags? Optimize Your Reduction Experiments

- What accessories are used with silicon carbide heating elements and their functions? Ensure Reliable Performance and Longevity

- Why is a high-purity Alumina Crucible required during the annealing of MoS2? Ensure High-Temperature Material Purity