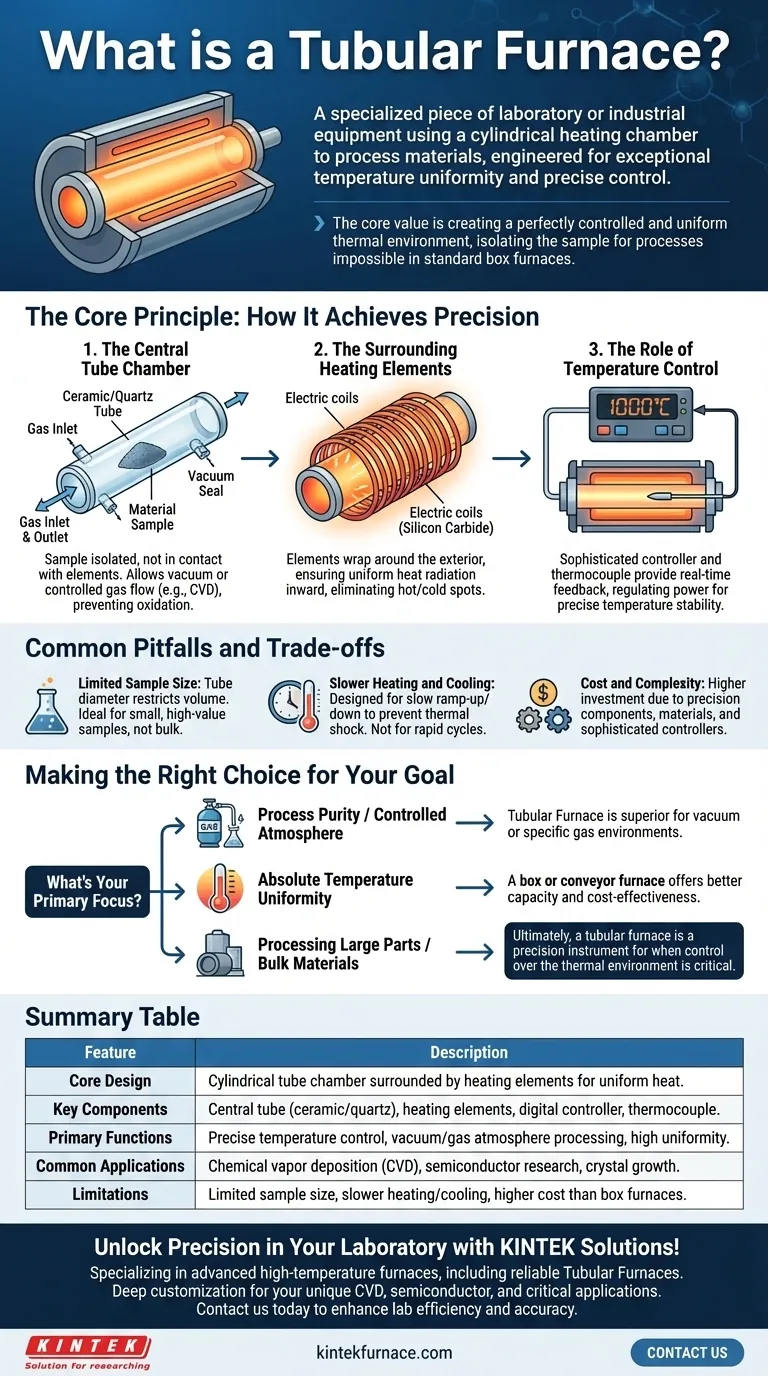

In essence, a tubular furnace is a specialized piece of laboratory or industrial equipment that uses a cylindrical heating chamber to process materials. Its defining feature is a central tube, typically made of ceramic or quartz, which is surrounded by electric heating elements. This design is not arbitrary; it is engineered for exceptional temperature uniformity and precise control over the heating environment.

The core value of a tubular furnace isn't just its ability to get hot, but its ability to create a perfectly controlled and uniform thermal environment. The tube isolates the sample, enabling processes that are impossible in standard box furnaces.

The Core Principle: How a Tubular Furnace Achieves Precision

A tubular furnace's design directly enables its primary functions: creating a highly uniform and controllable heating zone. This is achieved through the interaction of three key components.

The Central Tube Chamber

The material to be heated is placed inside the tube, not in direct contact with the heating elements. This tube can be sealed, allowing for processing in a vacuum or under a controlled flow of gas.

This isolation is critical for applications like chemical vapor deposition (CVD) or for preventing oxidation of sensitive materials.

The Surrounding Heating Elements

Electric heating elements, often made of materials like Kanthal or silicon carbide, are wrapped around the exterior of the central tube.

This configuration ensures that heat radiates inward from all directions, creating a highly uniform temperature zone along the center of the tube. It eliminates the hot and cold spots common in other furnace designs.

The Role of Temperature Control

These furnaces are almost always paired with a sophisticated digital controller. A temperature sensor, called a thermocouple, is placed near the heating elements or inside the tube to provide real-time feedback.

The controller uses this feedback to precisely regulate the power sent to the elements, allowing it to maintain a stable temperature setpoint, often within a single degree.

Common Pitfalls and Trade-offs

While powerful, the tubular furnace is a specialized tool with specific limitations. Understanding these is key to using it effectively.

Limited Sample Size

The diameter of the tube inherently restricts the size and volume of the material you can process. These furnaces are ideal for small, high-value samples, not for bulk material processing.

Slower Heating and Cooling

To maintain stability and prevent thermal shock to the ceramic tube, tubular furnaces are designed to heat up and cool down slowly. If high throughput and rapid temperature cycles are your priority, this design may be a bottleneck.

Cost and Complexity

The precision components, high-quality tube materials, and sophisticated controllers make tubular furnaces more expensive than simpler box furnaces of a similar power rating. They are an investment in precision, not just heat.

Making the Right Choice for Your Goal

Deciding if a tubular furnace is right for you depends entirely on the requirements of your process.

- If your primary focus is process purity and a controlled atmosphere: The sealed-tube design is a non-negotiable advantage for working with vacuums or specific gases.

- If your primary focus is absolute temperature uniformity: A tubular furnace is the superior choice for applications like crystal growth, semiconductor research, or calibrating sensors.

- If your primary focus is processing large parts or bulk materials: A box furnace or a conveyor furnace will offer a much better balance of capacity and cost-effectiveness.

Ultimately, a tubular furnace is a precision instrument designed for when control over the thermal environment is just as important as the temperature itself.

Summary Table:

| Feature | Description |

|---|---|

| Core Design | Cylindrical tube chamber surrounded by heating elements for uniform heat distribution. |

| Key Components | Central tube (ceramic/quartz), heating elements (e.g., Kanthal), digital controller with thermocouple. |

| Primary Functions | Precise temperature control, vacuum/gas atmosphere processing, high uniformity for sensitive materials. |

| Common Applications | Chemical vapor deposition (CVD), semiconductor research, crystal growth, sensor calibration. |

| Limitations | Limited sample size, slower heating/cooling rates, higher cost compared to box furnaces. |

Unlock Precision in Your Laboratory with KINTEK Solutions!

Are you working with sensitive materials that demand exact temperature control and uniform heating? KINTEK specializes in advanced high-temperature furnaces, including our reliable Tubular Furnaces, designed to meet the rigorous needs of diverse labs. With our exceptional R&D and in-house manufacturing, we offer deep customization to precisely fit your unique experimental requirements—whether for CVD processes, semiconductor development, or other critical applications.

Our product line, featuring Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, ensures you get the right tool for optimal results. Don't let equipment limitations hold back your research—contact us today to discuss how we can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency