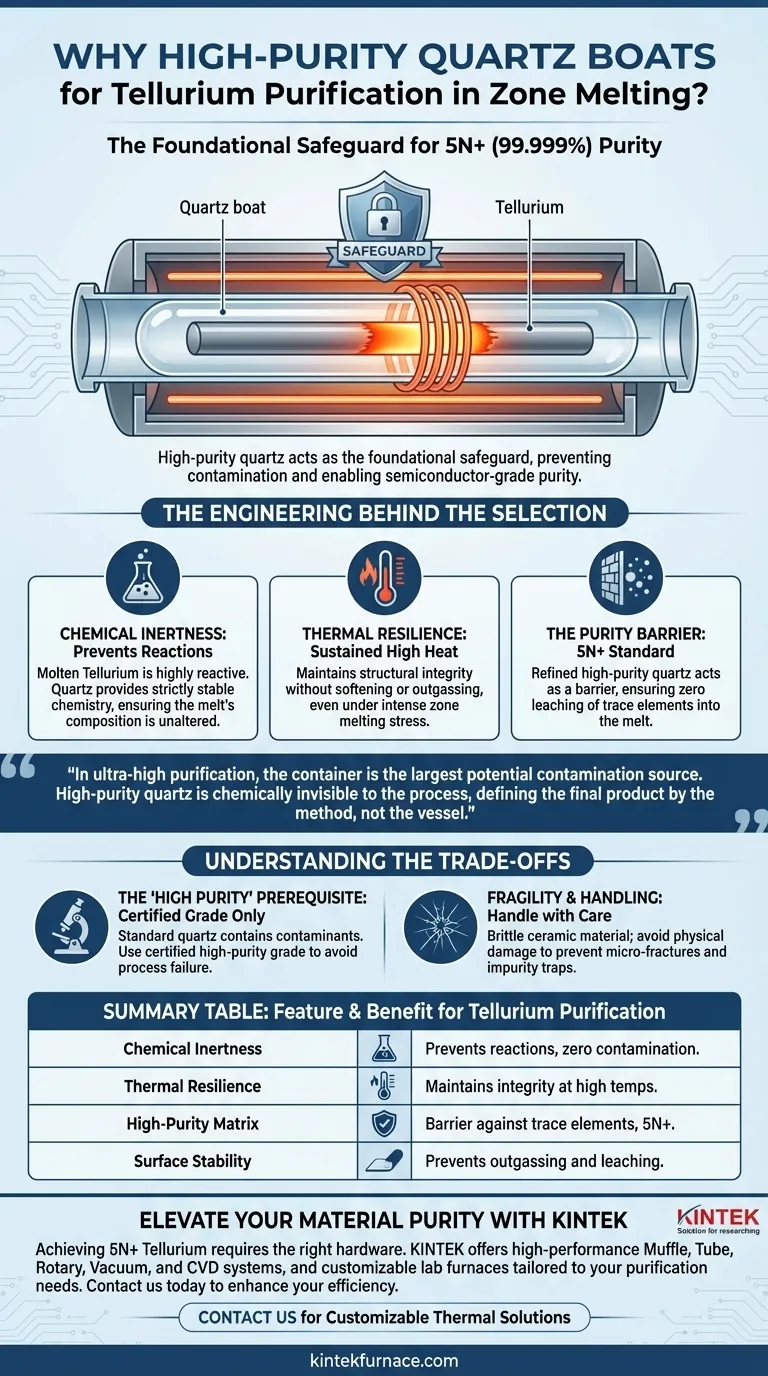

High-purity quartz acts as the foundational safeguard for the integrity of the zone melting process. It is selected primarily because it offers a unique combination of extreme thermal resistance and chemical inertness, preventing the container itself from contaminating the molten Tellurium. This choice is not merely about holding the material; it is a critical process variable required to achieve semiconductor-grade purity levels of 5N (99.999%) and higher.

In ultra-high purification, the container is often the largest source of potential contamination. High-purity quartz is the industry standard because it remains chemically invisible to the process, ensuring the final Tellurium product is defined by the purification method, not the vessel holding it.

The Engineering Behind the Selection

The choice of a boat for zone melting is a decision based on minimizing variables. To refine Tellurium successfully, the container must possess specific physical and chemical characteristics.

Chemical Inertness

The most critical requirement for a purification vessel is neutrality.

During the melting process, molten Tellurium becomes highly reactive. High-purity quartz provides strictly stable chemistry that does not react with the Tellurium. This ensures the chemical composition of the melt remains unaltered by the boat's surface.

Thermal Resilience

Zone melting subjects the equipment to sustained, intense heat.

Quartz is chosen for its exceptional high-temperature resistance. It maintains structural integrity without softening, deforming, or outgassing contaminants, even under the thermal stress required to melt Tellurium.

The Purity Barrier

A container cannot produce a product purer than itself.

The "high-purity" aspect of the quartz is just as important as the material itself. By using quartz refined to high standards, the boat acts as an effective barrier against external contaminants. It ensures that no impurities leach from the boat into the melt, which is the only way to achieve 5N+ purity.

Understanding the Trade-offs

While high-purity quartz is the superior technical choice, it is important to understand the constraints and requirements that come with using it.

The "High Purity" Prerequisite

Not all quartz is created equal. Standard quartz may contain trace elements that function as contaminants.

For Tellurium purification, you must specifically utilize high-purity grade quartz. Using lower-grade alternatives undermines the entire process, as impurities from the silica matrix can migrate into the molten Tellurium, rendering the zone melting ineffective.

Fragility and Handling

Despite its thermal robustness, quartz remains a brittle ceramic material.

It requires careful mechanical handling to prevent micro-fractures or surface scratching. Any physical damage to the boat's surface can create nucleation sites or traps for impurities, compromising the smooth transit of the molten zone.

Ensuring Process Integrity

When designing or operating a zone melting apparatus for Tellurium, your material selection defines your success ceiling.

- If your primary focus is achieving 5N+ Purity: You must prioritize the certified purity grade of the quartz boat to ensure zero leaching of trace elements.

- If your primary focus is Process Stability: Rely on the high-temperature resistance of quartz to maintain a consistent geometry and barrier throughout long heating cycles.

Ultimately, high-purity quartz is not just a container; it is a passive component of the purification system that makes ultra-high purity results possible.

Summary Table:

| Feature | Benefit for Tellurium Purification |

|---|---|

| Chemical Inertness | Prevents reactions between the melt and container, ensuring zero contamination. |

| Thermal Resilience | Maintains structural integrity under sustained high temperatures without deforming. |

| High-Purity Matrix | Acts as a barrier against trace elements, enabling 5N (99.999%) purity levels. |

| Surface Stability | Prevents outgassing and leaching of impurities into the molten zone. |

Elevate Your Material Purity with KINTEK

Achieving 5N+ semiconductor-grade Tellurium requires more than just process—it requires the right hardware. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored to your unique purification needs.

Don't let container contamination limit your results. Contact us today to discover our customizable thermal solutions and see how our expertise can enhance your laboratory's efficiency and output.

Visual Guide

References

- Shuai Guo, Junhua Hu. Establishment of “Structure‐Efficiency” Relationship in Ultra‐High Purity Metal Systems: Multi‐Scale Analysis of Tellurium as a Prototype. DOI: 10.1002/advs.202508531

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Induction Melting Furnace

People Also Ask

- Why is a silica crucible selected as the reaction vessel? Ensure Stability and Purity in High-Temp Synthesis

- What functions do alumina crucibles and quartz tube encapsulation serve? Essential Shields for Na2In2As3 Synthesis

- What is the function of glass tubes in molten-core thermal drawing? Precision Shaping and Chemical Isolation

- What maintenance is required for a water circulating vacuum pump? Ensure Peak Performance and Longevity

- What are the roles of rotameters and digital flow controllers in pneumatic systems? Enhance Precision and Testing

- What are the functions of a high-purity graphite mold during the SPS process? Beyond Containing the Powder

- Are customization options available for alumina ceramic furnace tubes? Tailor Them for Your Lab's Needs

- Why use high-precision gas flow control for argon in oil migration simulations? Achieve Re=215 Accuracy