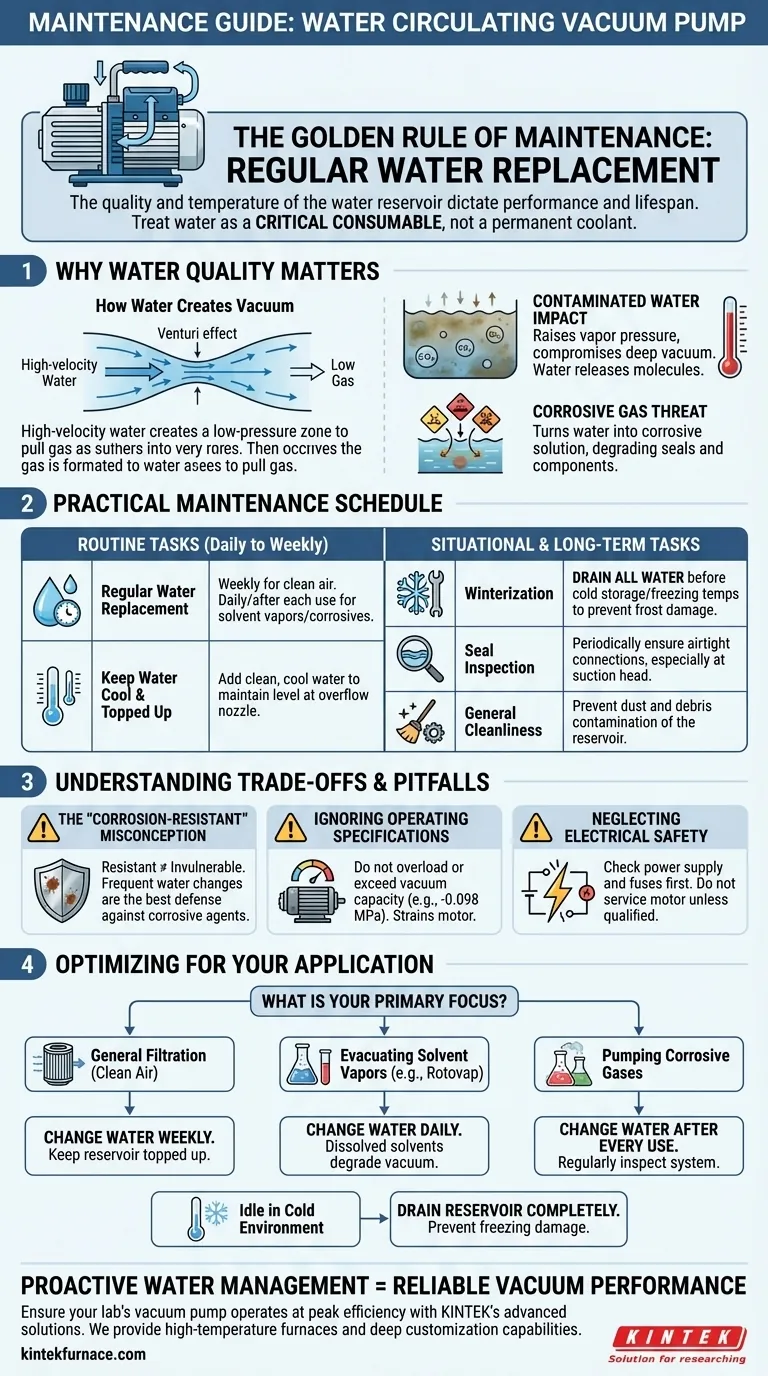

At its core, the required maintenance for a water circulating vacuum pump is simple: you must regularly replace the water in its reservoir. The quality and temperature of this water directly dictate the pump's vacuum performance and operational lifespan. Neglecting this single task is the primary cause of poor performance and eventual failure.

The most common mistake is treating the water as a permanent coolant. You must instead treat it as a critical, consumable working fluid that needs to be kept clean and cool to function correctly.

Why Water Quality Dictates Performance

A water circulating vacuum pump, often using a Venturi effect, relies entirely on the properties of its working fluid—the water. Understanding this relationship is key to effective maintenance.

How Water Creates the Vacuum

A high-velocity jet of water passes through a nozzle, creating a low-pressure zone that pulls gas molecules from the connected system. This gas mixes with the water stream and is then expelled into the reservoir.

The Impact of Contaminated Water

If the reservoir water is dirty or has gases dissolved in it, its ability to create a deep vacuum is compromised. Contaminants can raise the vapor pressure of the water, meaning the water itself will release molecules into the vacuum line, fighting against the vacuum you are trying to create.

The Threat of Corrosive Gases

When you pump corrosive gases, they dissolve into the water reservoir. This turns the water into a corrosive solution that continuously circulates through the pump, degrading seals, impellers, and even corrosion-resistant components over time.

A Practical Maintenance Schedule

Consistent, simple checks are far more effective than infrequent, complex overhauls. Your schedule should be adapted based on how you use the pump.

Routine Tasks (Daily to Weekly)

Regular Water Replacement is the most critical task. For general use with clean air, changing the water weekly is sufficient. If you are pumping solvent vapors or mild corrosives, you must change the water daily or even after each use.

Keep Water Cool and Topped Up by adding clean, cool water as needed. The initial setup requires filling the tank until the water level reaches the overflow nozzle. Maintaining this level ensures consistent operation.

Situational & Long-Term Tasks

Winterization is non-negotiable in cold environments. Before storing the pump or leaving it idle in temperatures near freezing, you must drain all water from the reservoir and lines to prevent frost damage, which can crack the housing or internal components.

Seal Inspection should be done periodically. Ensure all connections, especially at the suction head, are airtight. If you suspect a leak, you may need to add or replace sealing rings to maintain maximum vacuum.

General Cleanliness of the equipment and surrounding area prevents dust and debris from falling into the reservoir and contaminating the water.

Understanding the Trade-offs and Pitfalls

Even with their simple design, these pumps are subject to operational limits and common user errors.

The "Corrosion-Resistant" Misconception

Many pumps are built with stainless steel or other resistant materials. However, "resistant" does not mean "invulnerable." Constant exposure to highly corrosive agents dissolved in the water will eventually cause damage. Frequent water changes are your best defense.

Ignoring Operating Specifications

Every pump is rated for a specific flow rate and vacuum level (e.g., -0.098 MPa). Overloading the system or attempting to pull a vacuum beyond its ultimate capacity will not work and puts unnecessary strain on the motor.

Neglecting Electrical Safety

If the motor fails to start, first check the power supply and fuses. Do not attempt to service the motor itself unless you are a qualified electrician.

Optimizing Maintenance for Your Application

Tailor your maintenance routine to your specific task to ensure reliability and extend the life of your pump.

- If your primary focus is general filtration with clean air: Change the water weekly and keep the reservoir topped up to maintain consistent performance.

- If your primary focus is evacuating solvent vapors (e.g., from a rotovap): Change the water daily, as dissolved solvents will significantly degrade the ultimate vacuum depth.

- If your primary focus is pumping known corrosive gases: Change the water after every single use and regularly inspect the system for any signs of degradation.

- If your pump will be idle in a cold environment: Always drain the reservoir completely to prevent catastrophic damage from freezing.

Proactive water management is the single most effective strategy for guaranteeing your vacuum pump remains a reliable tool for your work.

Summary Table:

| Maintenance Task | Frequency | Key Benefit |

|---|---|---|

| Water Replacement | Daily to weekly | Prevents contamination and maintains vacuum depth |

| Keep Water Cool and Topped Up | As needed | Ensures consistent operation and efficiency |

| Winterization | Before cold storage | Avoids frost damage to components |

| Seal Inspection | Periodically | Maintains airtight connections and vacuum integrity |

| General Cleanliness | Regularly | Reduces debris and contamination risks |

Ensure your lab's vacuum pump operates at peak efficiency with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs. Contact us today to discuss how we can enhance your equipment reliability and performance!

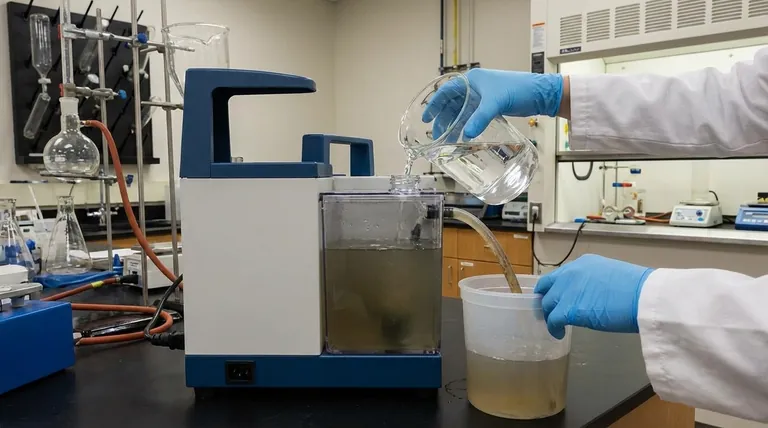

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is a stainless steel crucible selected for melting AM60 magnesium alloy? Ensure Alloy Purity and Safety

- Why are Zirconium Dioxide (ZrO2) crucibles used for slag-metal experiments? Ensure High-Temperature Chemical Purity

- Why is a high-purity graphite crucible preferred for (AgCu)0.999Te0.69Se0.3S0.01 preparation? Ensure Peak Purity.

- Why must the reaction containers be sealed within a fused quartz tube? Protect Your Crystal Growth Integrity

- What are the main features of a water circulating vacuum pump compared to a desktop pump? Discover Key Differences for Your Lab

- Why is a BN coating used in Mg3Sb2 melting? Essential Purity and Protection Guide

- Why is a graphite crucible preferred for SiNQ synthesis? Master Heat Management in Magnesiothermic Reduction

- What is the role of an optical pyrometer in diffusion bonding? Ensure Precision in High-Temperature Simulations