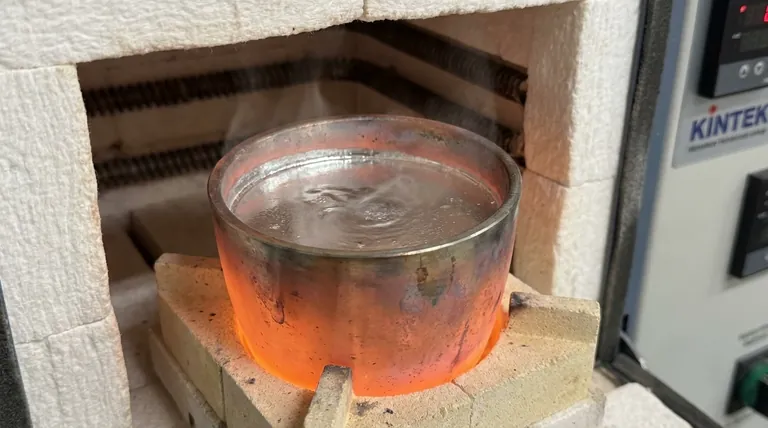

In high-temperature metallurgy, the container is as critical as the contents. A stainless steel crucible is selected for melting AM60 magnesium alloy primarily for two reasons: its exceptional high-temperature strength and its chemical inertness. It can withstand the required refining temperatures of 973-993K (700-720°C) without deforming, ensuring structural integrity. More importantly, it is relatively unreactive with the highly aggressive molten magnesium, which prevents contamination and preserves the final alloy's precise chemical composition.

The selection of a crucible for a reactive metal like magnesium goes beyond simple heat tolerance. The critical factor is finding a material that provides both structural stability at high temperatures and chemical compatibility to prevent catastrophic contamination of the final alloy.

The Twin Pillars of Crucible Selection

When working with molten metals, especially highly reactive ones like magnesium alloys, the choice of crucible material is governed by two fundamental requirements. Failure to meet either one can lead to process failure, compromised products, or dangerous safety incidents.

Ensuring Structural Integrity Under Heat

The refining process for AM60 magnesium alloy occurs at a very high temperature range of 973-993K. At these temperatures, many common metals would soften, lose their structural strength, and deform under the weight of the molten metal.

A key advantage of stainless steel is its excellent high-temperature strength. It reliably maintains its shape and rigidity within this operational window, ensuring the molten alloy is securely contained without risk of a breach or spill.

Preventing Chemical Contamination

Molten magnesium is extremely reactive. It has a strong tendency to react with or dissolve other materials it comes into contact with, including its container.

Stainless steel is chosen because it is relatively unreactive with molten magnesium. This chemical stability is crucial for preventing elements from the crucible (like excess iron or nickel) from leaching into the melt. This ensures the chemical integrity of the AM60 alloy is maintained, which is essential for achieving its desired mechanical properties.

The Hidden Danger: Alloy Purity

The term "alloy" refers to a metal with a very precise recipe of constituent elements. The performance of the final cast part—its strength, corrosion resistance, and weight—depends entirely on maintaining that exact recipe.

The Problem with Impurities

If the crucible reacts with the molten magnesium, it introduces impurities. Even a small percentage of contamination from the crucible material can drastically alter the properties of the AM60 alloy.

This can lead to final products that fail to meet engineering specifications, resulting in rejected batches, wasted resources, and potential in-service failures. Using a non-reactive crucible is a fundamental step in quality control.

Why Material Compatibility is Non-Negotiable

The high reactivity of magnesium means that an incompatible crucible material would be actively dissolved into the molten bath. This not only contaminates the alloy but also degrades the crucible itself, eventually leading to structural failure.

Stainless steel provides the necessary barrier, acting as a stable and reliable container that protects the purity of the alloy throughout the melting and refining process.

Understanding the Trade-offs

While stainless steel is an excellent choice for this application, no material selection is without its compromises. Acknowledging these trade-offs is key to a robust engineering process.

"Relatively Unreactive" is Not "Inert"

The term "relatively unreactive" is important. It implies that over many heating cycles, some minimal interaction may still occur. Crucibles are consumable items with a finite service life and must be inspected and replaced periodically.

The Cost Factor

Stainless steel alloys are significantly more expensive than simpler materials like carbon or mild steel. However, this higher upfront cost is justified by the prevention of costly contamination and the assurance of operational safety, resulting in a lower total cost of ownership.

Making the Right Choice for Your Process

Your specific priorities will dictate why the properties of stainless steel are so critical for your application.

- If your primary focus is alloy purity and quality: The chemical inertness of stainless steel is non-negotiable to prevent the contamination that ruins the alloy's specified properties.

- If your primary focus is operational safety: The high-temperature strength of stainless steel ensures the crucible won't deform or fail, preventing catastrophic and dangerous spills of molten metal.

- If your primary focus is process reliability: Choosing stainless steel minimizes the risk of batch rejection due to impurities, ensuring a consistent and predictable manufacturing output.

Ultimately, selecting a stainless steel crucible for melting AM60 is a foundational engineering decision that directly safeguards the quality, safety, and success of the entire metallurgical process.

Summary Table:

| Crucible Requirement | Stainless Steel Advantage |

|---|---|

| Structural Integrity | Excellent high-temperature strength (up to 720°C) prevents deformation |

| Chemical Inertness | Relatively unreactive with molten magnesium, preventing contamination |

| Alloy Purity | Maintains precise AM60 chemical composition for consistent properties |

| Operational Safety | Prevents catastrophic spills and ensures process reliability |

Ready to Safeguard Your High-Temperature Processes?

Choosing the right crucible is critical for the purity, safety, and reliability of your metallurgical work. KINTEK understands the precise demands of high-temperature applications.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our solutions are designed to handle reactive materials like magnesium alloys with the utmost precision.

Let us help you achieve consistent, high-quality results. Contact our experts today to discuss a custom solution for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure