To be clear, you are prohibited from ever introducing any kind of liquids or molten metal directly into the furnace chamber. This is an absolute rule based on fundamental safety principles designed to prevent catastrophic equipment failure and protect personnel from explosive events.

The core principle is not merely about specific substances, but about preventing rapid, uncontrolled thermal and pressure changes. Introducing liquids or molten metal creates conditions for violent reactions that the furnace is not designed to contain.

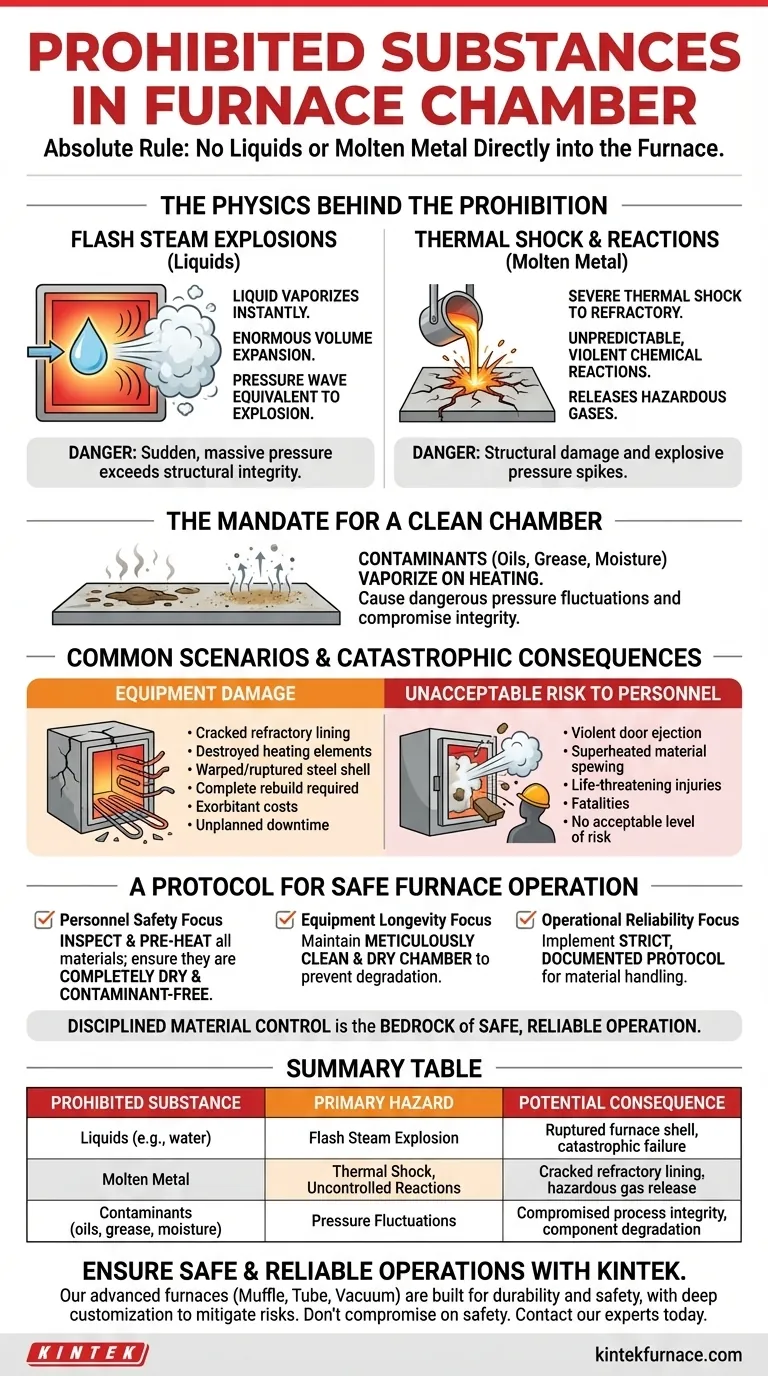

The Physics Behind the Prohibition

Understanding why these rules exist is critical for maintaining a safe and efficient operation. The restrictions are rooted in preventing two primary types of violent events: flash steam explosions and uncontrolled chemical reactions.

The Danger of Liquids: Flash Steam Explosions

When a liquid, especially water, is introduced into a high-temperature furnace chamber, it does not simply boil—it vaporizes instantly.

This near-instantaneous phase change from liquid to gas is known as a flash steam event. The volume expansion is enormous and incredibly fast, creating a pressure wave equivalent to an explosion.

This sudden, massive increase in internal pressure can easily exceed the structural integrity of the furnace, leading to catastrophic failure.

The Risk of Molten Metal: Thermal Shock and Reactions

Introducing external molten metal can be just as dangerous, though for slightly different reasons.

It can cause severe thermal shock to the furnace refractory lining, leading to cracking and immediate structural damage.

Furthermore, the molten metal can react violently and unpredictably with the furnace atmosphere or any contaminants present on the chamber floor, releasing hazardous gases or causing further explosive pressure spikes.

The Mandate for a Clean Chamber

The requirement to keep the furnace chamber clean at all times is directly related to these principles.

Contaminants like residual oils, grease, or even trapped moisture in dirt and debris can vaporize upon heating. While the effect may be smaller than a direct liquid injection, it can still cause dangerous pressure fluctuations and compromise the integrity of both the equipment and the material being processed.

Common Scenarios and Catastrophic Consequences

Failing to adhere to these rules is not a minor operational misstep; it is a direct cause of severe industrial accidents. Understanding the consequences underscores the importance of the prohibition.

Potential for Equipment Damage

A pressure event can crack the refractory lining, destroy heating elements, and warp or rupture the furnace's steel shell.

The resulting damage often requires a complete furnace rebuild, leading to exorbitant costs and extended, unplanned downtime.

Unacceptable Risk to Personnel

The most critical consequence is the extreme danger to anyone near the furnace.

An explosive event can violently eject the furnace door, spew superheated material across the facility, and cause life-threatening injuries or fatalities. There is no acceptable level of risk when it comes to this hazard.

A Protocol for Safe Furnace Operation

Translating these principles into action requires a disciplined approach to material handling and furnace charging.

- If your primary focus is personnel safety: The absolute rule is to inspect and pre-heat all materials to ensure they are completely dry and free of any contaminants before charging.

- If your primary focus is equipment longevity: Maintaining a meticulously clean and dry furnace chamber is the most effective way to prevent the thermal and pressure shocks that degrade components over time.

- If your primary focus is operational reliability: A strict, documented protocol for material handling prevents the catastrophic accidents that lead to unpredictable and costly downtime.

Ultimately, disciplined material control is the bedrock of safe, reliable, and effective furnace operation.

Summary Table:

| Prohibited Substance | Primary Hazard | Potential Consequence |

|---|---|---|

| Liquids (e.g., water) | Flash Steam Explosion | Ruptured furnace shell, catastrophic failure |

| Molten Metal | Thermal Shock, Uncontrolled Reactions | Cracked refractory lining, hazardous gas release |

| Contaminants (oils, grease, moisture) | Pressure Fluctuations | Compromised process integrity, component degradation |

Ensure your furnace operations are safe and reliable. The risks of improper material handling are too great to ignore. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions—like our Muffle, Tube, and Vacuum Furnaces—that are built for durability and safety. Our strong deep customization capability allows us to design systems that precisely meet your unique experimental requirements and incorporate safety features to mitigate risks. Don't compromise on safety. Contact our experts today to discuss a furnace solution that protects your personnel and your investment.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals