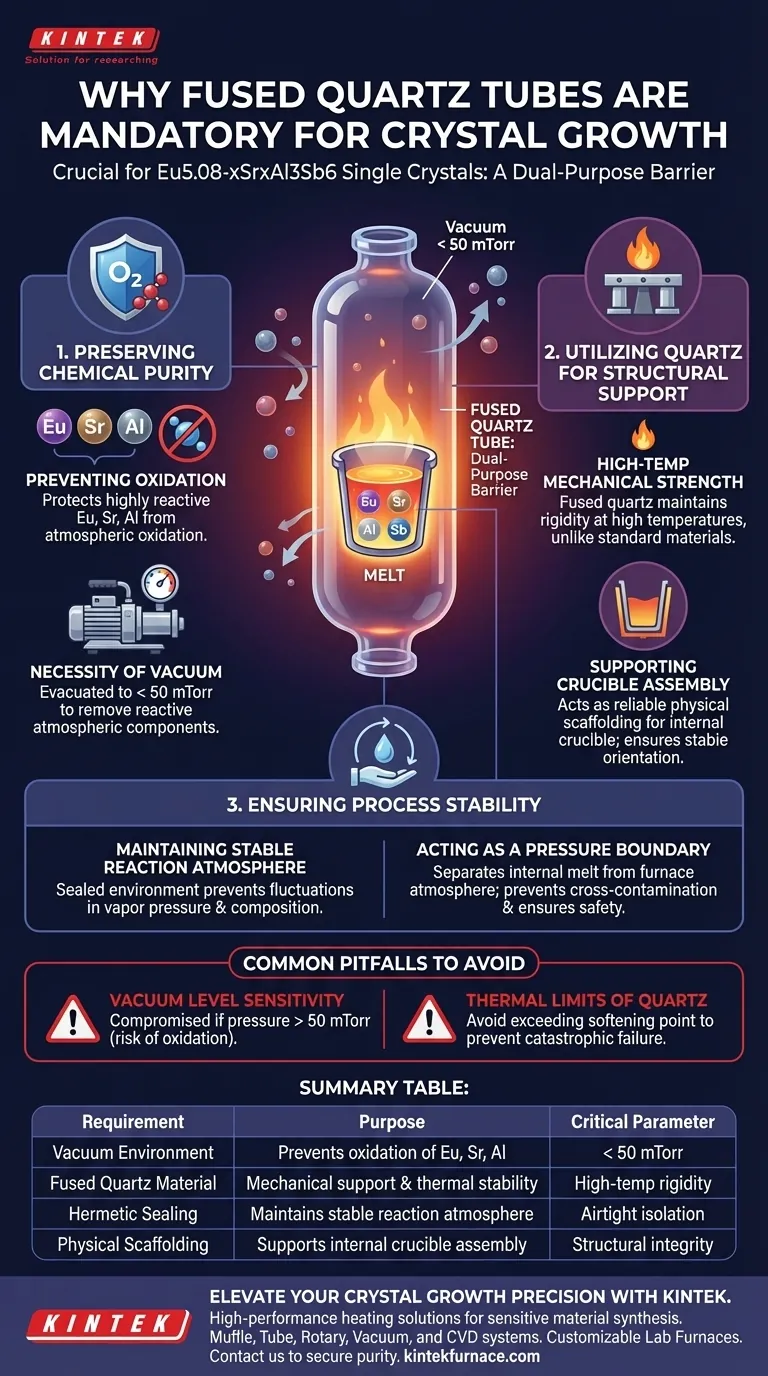

The use of fused quartz tubes is mandatory to prevent chemical degradation and ensure structural integrity during the crystal growth process. Specifically, sealing the container allows for the creation of a vacuum environment (below 50 mTorr), which shields reactive raw materials like europium, strontium, and aluminum from atmospheric oxidation. Simultaneously, the fused quartz retains the mechanical strength needed to physically support the crucible assembly during high-temperature processing.

By sealing the reaction in fused quartz, you create a dual-purpose barrier: it chemically isolates sensitive elements from oxygen while providing the physical scaffolding necessary to withstand high thermal stress.

Preserving Chemical Purity

The primary challenge in growing $Eu_{5.08-x}Sr_xAl_3Sb_6$ crystals is the high reactivity of the raw materials.

Preventing Oxidation of Active Elements

Raw materials such as europium, strontium, and aluminum are chemically "active." If exposed to air at high temperatures, these elements will rapidly oxidize, ruining the stoichiometry of the crystal.

The Necessity of a Vacuum Environment

To counteract this, the quartz tube is evacuated to a pressure below 50 mTorr. This vacuum effectively removes atmospheric components that would otherwise react with the melt.

Utilizing Quartz for Structural Support

Beyond chemical isolation, the physical container must survive the rigorous thermal environment of crystal growth.

High-Temperature Mechanical Strength

Standard materials often soften or warp under the intense heat required for this reaction. Fused quartz is unique because it maintains excellent mechanical strength at these elevated temperatures.

Supporting the Crucible Assembly

Because the quartz remains rigid, it acts as a reliable support structure for the internal crucible assembly. This ensures that the physical orientation of the growth container remains stable throughout the process.

Ensuring Process Stability

The sealed tube functions as a controlled micro-environment for the duration of the experiment.

Maintaining a Stable Reaction Atmosphere

The sealed environment prevents fluctuations in the reaction atmosphere. This isolation ensures that the vapor pressure and chemical composition remain constant relative to the outside air.

Acting as a Pressure Boundary

Drawing from general crystal growth principles, the sealed tube also acts as a pressure boundary. This separates the internal melt environment from the furnace atmosphere, ensuring process safety and preventing cross-contamination.

Common Pitfalls to Avoid

While fused quartz is essential, relying on it requires strict adherence to vacuum protocols.

Vacuum Level Sensitivity

The protection provided by the tube is only as good as the vacuum seal. If the internal pressure rises above 50 mTorr, the protection is compromised, and oxidation of the rare earth and alkaline earth metals is likely to occur.

Thermal limits of Quartz

While quartz has high strength, it is not indestructible. It is critical to ensure the process temperatures do not exceed the softening point of the quartz itself, which would lead to catastrophic structural failure.

Making the Right Choice for Your Goal

To ensure high-quality single crystal growth, focus on the following parameters:

- If your primary focus is Material Purity: Ensure your vacuum pump system can consistently achieve and hold a pressure below 50 mTorr before sealing the tube to protect the europium and strontium.

- If your primary focus is Process Safety: Verify the wall thickness and quality of the fused quartz to ensure it can mechanically support the crucible load at peak temperatures.

Success depends on treating the quartz tube not just as a container, but as a critical component of the reaction's chemical and physical control system.

Summary Table:

| Requirement | Purpose | Critical Parameter |

|---|---|---|

| Vacuum Environment | Prevents oxidation of Eu, Sr, and Al | < 50 mTorr |

| Fused Quartz Material | Mechanical support & thermal stability | High-temp rigidity |

| Hermetic Sealing | Maintains stable reaction atmosphere | Airtight isolation |

| Physical Scaffolding | Supports internal crucible assembly | Structural integrity |

Elevate Your Crystal Growth Precision with KINTEK

Don't let oxidation or structural failure compromise your research. KINTEK provides high-performance heating solutions designed for sensitive material synthesis. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored to your unique specifications.

Whether you are growing complex single crystals or conducting advanced metallurgy, our equipment ensures the stable, controlled environments your work demands. Contact KINTEK today to discuss your custom furnace needs and secure the purity of your next project!

Visual Guide

References

- Luis Garay, Susan M. Kauzlarich. Interplay of Crystal Structure and Magnetic Properties of the Eu<sub>5.08-x</sub>Sr<sub><i>x</i></sub>Al<sub>3</sub>Sb<sub>6</sub> Solid Solution. DOI: 10.1021/acs.inorgchem.4c04927

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What is the function of a high-precision mass flow controller (MFC) in CdS nanobelt vapor deposition?

- What is the purpose of using specialized vacuum glass tubes for sampling? Ensure KR Stirring Chemical Integrity

- How does a high-precision laboratory hydraulic press ensure structural consistency? Mastering Ceramic Green Bodies

- What are the primary functions of high-purity graphite molds in SPS? Optimize Your Spark Plasma Sintering Process

- What key functions do graphite molds perform in RuTi alloy sintering? Achieve High-Density Precision at 1000°C

- Why is a vacuum pumping system essential for DD6 alloy and ceramic shell experiments? Achieve High-Purity Results

- How does choosing alumina vs graphite crucibles affect Al-Si melting? Expert Guide to Data Integrity

- Why is toluene used as a grinding aid in wet ball milling? Master Fine Metal Powder Synthesis with PCAs