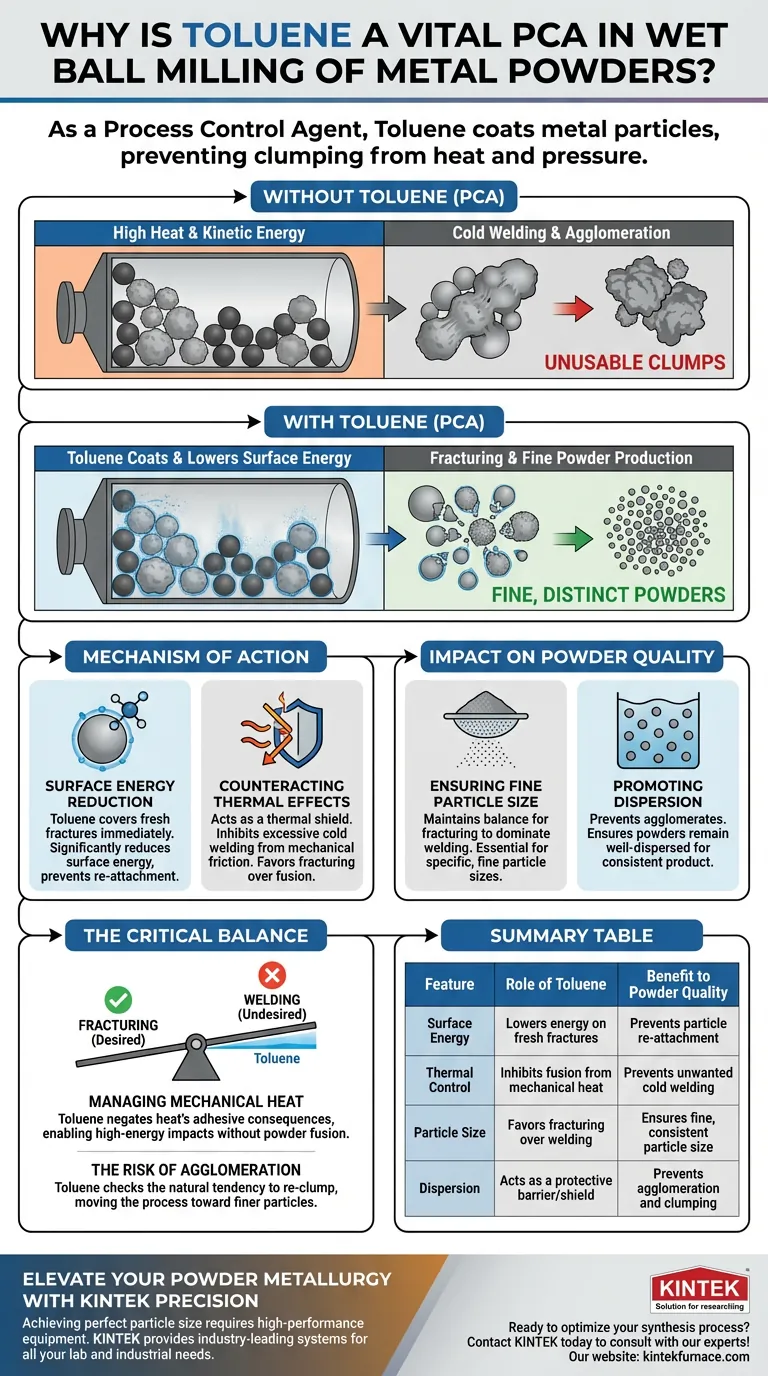

Toluene serves as a vital Process Control Agent (PCA) in the wet ball milling of metal powders. It functions by coating the metal particles to lower their surface energy, which directly prevents the powder from clumping or welding together due to the intense heat generated by mechanical impacts.

Without a PCA like toluene, the kinetic energy of milling converts to heat, causing metal particles to fuse rather than fracture. Toluene acts as a shield, inhibiting cold welding to ensure the production of fine, distinct powders.

The Mechanism of Action

Surface Energy Reduction

During milling, metal particles are constantly fractured, creating fresh, highly reactive surfaces. Toluene effectively covers these surfaces immediately upon formation.

By coating the particles, toluene significantly reduces their surface energy. This reduction is the primary chemical mechanism that prevents the particles from re-attaching to one another.

Counteracting Thermal Effects

The mechanical impact of ball milling generates significant friction and heat. In the absence of a control agent, this heat promotes excessive cold welding, where particles fuse together into larger agglomerates.

Toluene acts as a barrier to this thermal fusion. It ensures that the mechanical force results in particle size reduction (fracturing) rather than particle growth (welding).

The Impact on Powder Quality

Ensuring Fine Particle Size

The ultimate goal of milling is to produce specific, fine particle sizes. Toluene enables this by maintaining a balance where fracturing dominates over welding.

Without this intervention, the process would likely result in coarse, unusable clumps rather than fine powder.

Promoting Dispersion

Beyond size reduction, uniformity is critical. Toluene ensures the metal powders remain well-dispersed throughout the fluid medium.

This dispersion prevents the formation of agglomerates, leading to a consistent and high-quality final product.

The Critical Balance: Fracturing vs. Welding

Managing Mechanical Heat

The inherent trade-off in ball milling is that the same kinetic energy required to crush the metal also generates the heat that fuses it. You cannot have high-impact milling without generating heat.

Toluene does not eliminate the heat, but it negates its adhesive consequences. It allows you to maintain high-energy impacts without sacrificing the integrity of the powder.

The Risk of Agglomeration

If the surface energy is not managed, agglomeration becomes inevitable. This reverses the work of the mill, turning what should be fine powder back into larger masses.

Toluene is essentially the "check" on this natural physical tendency, ensuring the process moves in only one direction: toward finer particles.

Optimizing for Powder Quality

To ensure your wet ball milling process yields the best results, consider how the PCA aligns with your specific objectives.

- If your primary focus is Particle Size Reduction: Rely on toluene to inhibit cold welding, allowing the mechanical impact to effectively fracture particles into finer grades.

- If your primary focus is Mixture Homogeneity: Use toluene to lower surface energy, preventing clumping and ensuring a well-dispersed, uniform powder mixture.

By managing surface energy and thermal effects, toluene transforms a chaotic, high-heat environment into a controlled process for precision powder synthesis.

Summary Table:

| Feature | Role of Toluene in Wet Ball Milling | Benefit to Powder Quality |

|---|---|---|

| Surface Energy | Lowers energy on fresh fractures | Prevents particle re-attachment |

| Thermal Control | Inhibits fusion from mechanical heat | Prevents unwanted cold welding |

| Particle Size | Favors fracturing over welding | Ensures fine, consistent particle size |

| Dispersion | Acts as a protective barrier/shield | Prevents agglomeration and clumping |

Elevate Your Powder Metallurgy with KINTEK Precision

Achieving the perfect particle size requires more than just the right Process Control Agent—it demands high-performance equipment. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific lab and industrial requirements. Backed by expert R&D and precision manufacturing, our high-temperature furnaces and milling solutions help you manage surface energy and thermal effects with ease.

Ready to optimize your synthesis process? Contact KINTEK today to consult with our experts!

Visual Guide

References

- Tailoring Mechanical Properties of Al-Cr-Cu-Fe-Mn-Ni Complex Concentrated Alloys Prepared Using Pressureless Sintering. DOI: 10.3390/ma18174068

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What industrial applications utilize quartz tubes? Essential for High-Temp, Pure Processes

- What are the thermal properties of alumina tubes? Discover Their High-Temp Durability and Stability

- What are the technical advantages of using a high-purity alumina crucible for the synthesis of MnBi2Te4?

- Why is a laboratory reactor necessary for modified phenolic resin synthesis? Achieve Precision in Polymerization

- What role does a high-purity graphite mold play during the SPS sintering process of Al2O3-TiC? Unlock Process Efficiency

- Why is a high-purity graphite crucible typically chosen for the high-temperature vacuum carbothermic reduction of magnesium oxide?

- Why is a laboratory vacuum drying oven utilized for recovered carbon black? Preserve rCB Integrity and Pore Structure

- Why is dimensional accuracy important for alumina ceramic furnace tubes? Ensure Reliable High-Temp Performance