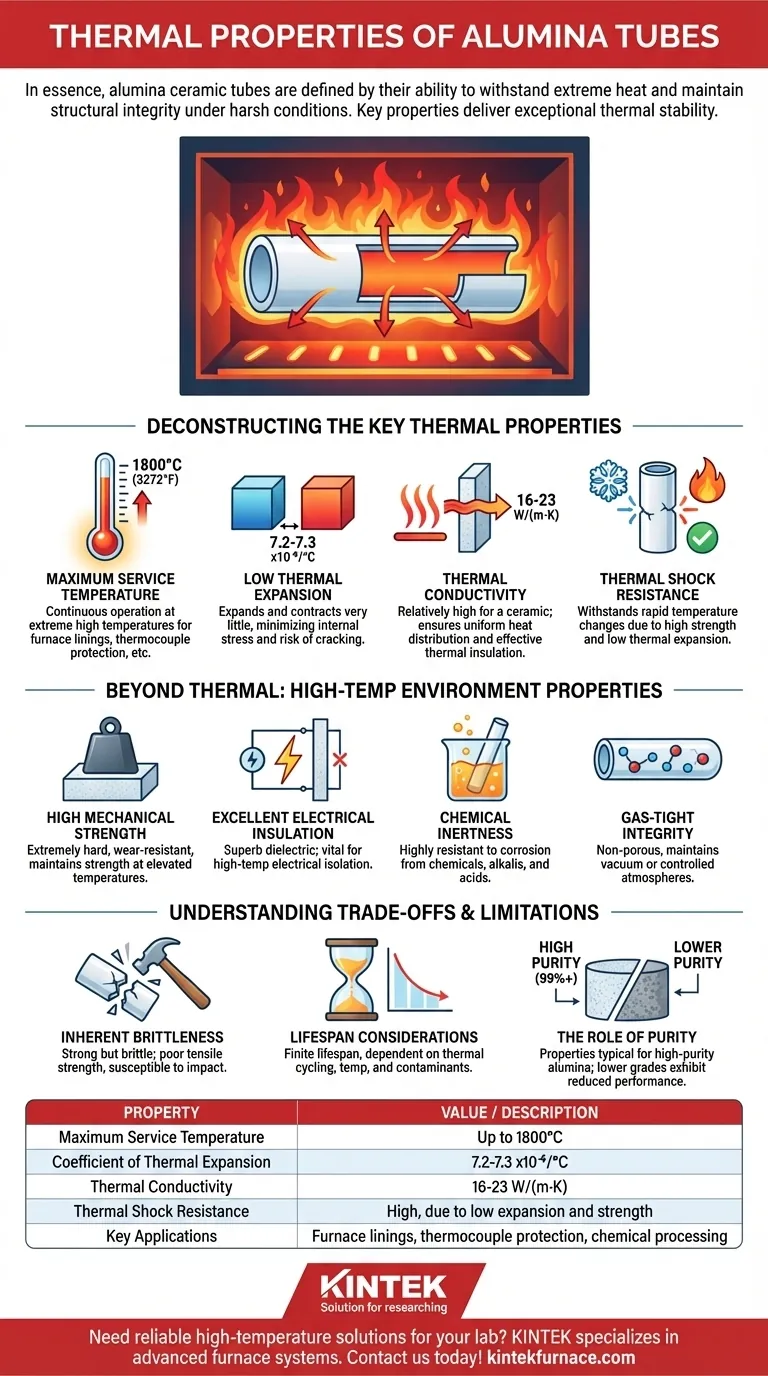

In essence, alumina ceramic tubes are defined by their ability to withstand extreme heat and maintain structural integrity under harsh conditions. Their primary thermal properties include a maximum service temperature up to 1800°C, a low coefficient of thermal expansion of 7.2-7.3 x10⁻⁶/°C, and a moderate thermal conductivity for a ceramic, typically between 16 and 23 W/(m·K).

The true value of alumina lies not just in its high-temperature tolerance, but in the combination of properties that deliver exceptional thermal stability. Its low expansion, moderate heat transfer, and high mechanical strength work together to resist thermal shock and ensure reliability in demanding applications.

Deconstructing the Key Thermal Properties

Understanding how each thermal property contributes to overall performance is critical for selecting the right material for your application.

Maximum Service Temperature

Alumina tubes can operate continuously at extremely high temperatures, with some grades rated for use up to 1800°C (3272°F).

This makes them a default choice for high-temperature furnace linings, thermocouple protection tubes, and other components in metallurgy, chemical processing, and advanced research.

Low Thermal Expansion

Alumina exhibits a low coefficient of thermal expansion. This means the material expands and contracts very little when its temperature changes.

This property is crucial for maintaining dimensional stability and minimizing internal stresses during heating and cooling cycles. Lower stress directly translates to a lower risk of cracking.

Thermal Conductivity

For a ceramic, alumina has a relatively high thermal conductivity of 16-23 W/(m·K). However, compared to metals, it is a thermal insulator.

This characteristic is beneficial in applications like furnace tubes where you want uniform heat distribution across the tube's surface. In other cases, it provides effective thermal insulation compared to any metal alternative.

Thermal Shock Resistance

Thermal shock resistance is the ability to withstand rapid changes in temperature without cracking. It is not a single property but a result of several factors.

Alumina's good thermal shock resistance stems from its high mechanical strength combined with its low thermal expansion. This allows it to dissipate thermal stresses before they can build up to a critical failure point.

Beyond Thermal: Properties for High-Temp Environments

The usefulness of alumina tubes is reinforced by a suite of non-thermal properties that are essential for survival in their intended operating environments.

High Mechanical Strength and Hardness

Alumina is an extremely hard and wear-resistant material with high compressive strength. It maintains this strength even at elevated temperatures, preventing deformation under load.

Excellent Electrical Insulation

Alumina is a superb electrical insulator (a dielectric material). This property is vital for applications requiring electrical isolation at high temperatures, such as in heaters and electronic component manufacturing.

Chemical Inertness

These tubes are highly resistant to corrosion and attack from a wide range of chemicals, alkalis, and acids, even at high temperatures. This makes them ideal for containing reactive or corrosive processes.

Gas-Tight Integrity

High-purity alumina tubes are non-porous and can be manufactured to be gas-tight. This is essential for maintaining a vacuum or a controlled protective atmosphere inside a furnace.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the limitations of alumina is key to successful implementation and avoiding premature failure.

Inherent Brittleness

Like most ceramics, alumina is strong but brittle. It has excellent compressive strength but poor tensile strength and is highly susceptible to failure from mechanical impact or shock. Care must be taken during installation and operation to avoid impacts.

Lifespan Considerations

While durable, the lifespan of an alumina tube is finite. It is highly dependent on the severity of thermal cycling, the maximum operating temperature, and the presence of chemical contaminants, which can accelerate degradation over time.

The Role of Purity

The properties described here are typical for high-purity alumina (e.g., 99%+). Lower-purity grades are less expensive but will exhibit a lower maximum service temperature and reduced performance in all categories.

Making the Right Choice for Your Application

Use your primary goal to determine if alumina is the correct fit.

- If your primary focus is extreme temperature survival: Alumina is a premier choice, capable of operating in environments where most metals would fail.

- If your primary focus is thermal stability and precision: The low thermal expansion ensures components remain dimensionally stable and reliable through thermal cycles.

- If your primary focus is electrical insulation at high temperatures: Alumina is one of the best and most widely used materials for this purpose.

- If your primary focus is surviving mechanical impact: You should consider adding protective measures or exploring tougher, though less heat-resistant, alternative materials.

Ultimately, alumina's combination of thermal resilience and structural integrity makes it an indispensable material for high-performance engineering.

Summary Table:

| Property | Value / Description |

|---|---|

| Maximum Service Temperature | Up to 1800°C |

| Coefficient of Thermal Expansion | 7.2-7.3 x10⁻⁶/°C |

| Thermal Conductivity | 16-23 W/(m·K) |

| Thermal Shock Resistance | High, due to low expansion and strength |

| Key Applications | Furnace linings, thermocouple protection, chemical processing |

Need reliable high-temperature solutions for your lab? KINTEK specializes in advanced furnace systems like Muffle, Tube, and Vacuum Furnaces, with deep customization to meet your unique thermal requirements. Contact us today to enhance your experimental precision and durability!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity