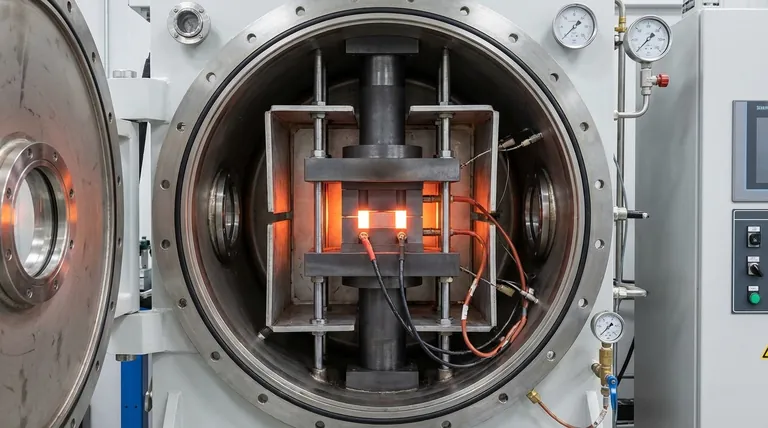

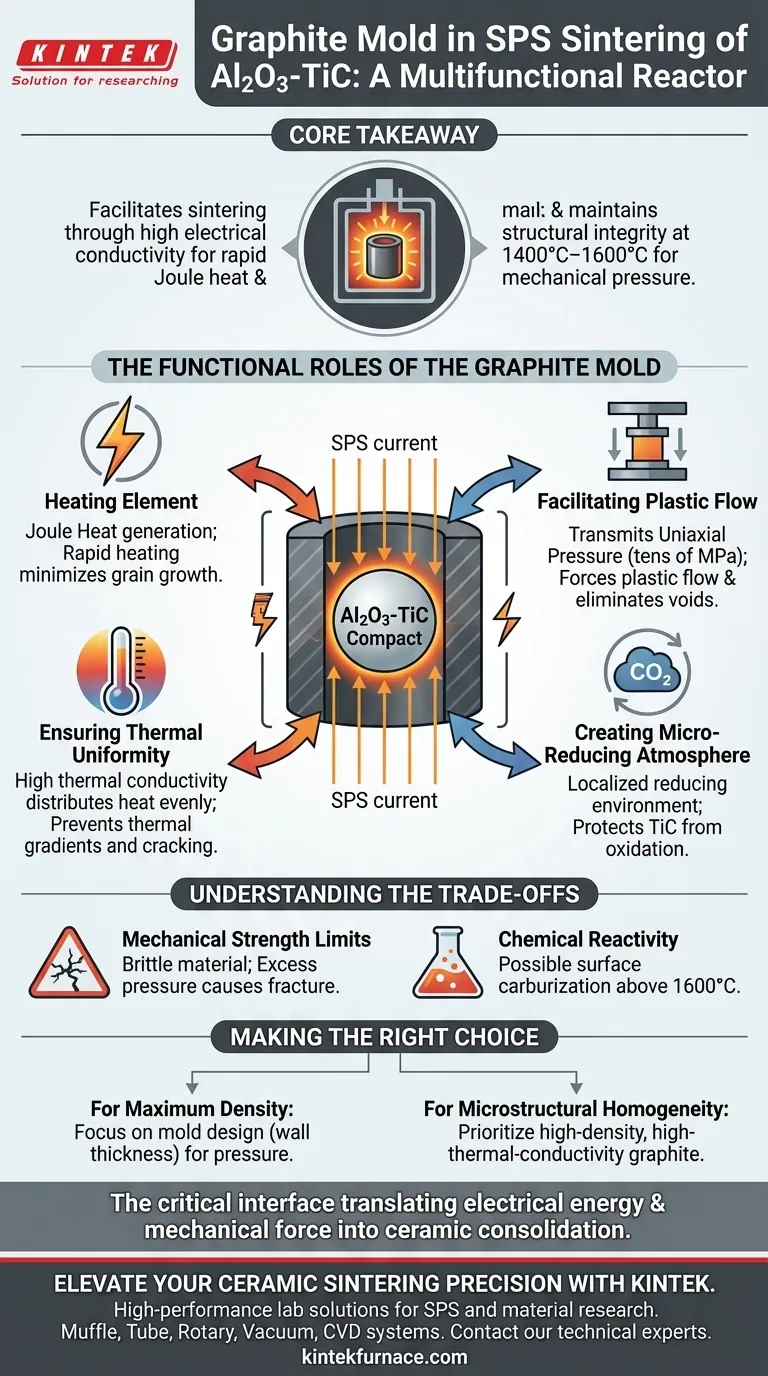

In the Spark Plasma Sintering (SPS) of Al2O3-TiC composites, the high-purity graphite mold serves as a multifunctional reactor rather than a passive container. It acts simultaneously as the mechanical die for shaping the powder, the physical ram for transmitting axial pressure, and the active resistance heating element that generates the thermal energy required for densification.

Core Takeaway The graphite mold facilitates the sintering of Al2O3-TiC by leveraging its high electrical conductivity to generate rapid Joule heat while simultaneously maintaining enough structural integrity at extreme temperatures (1400°C–1600°C) to transmit the mechanical pressure necessary for plastic flow and particle diffusion.

The Functional Roles of the Graphite Mold

1. The Mold as the Heating Element

In conventional sintering, heat is applied externally. In SPS, the graphite mold is part of the electrical circuit.

Because the mold possesses high electrical conductivity, the high current utilized in SPS flows directly through the mold walls.

This resistance generates Joule heat rapidly and directly around the Al2O3-TiC powder. This allows for fast heating rates that minimize grain growth, a critical factor in maintaining the mechanical properties of the final ceramic composite.

2. Facilitating Plastic Flow via Pressure

Al2O3-TiC composites require significant mechanical force to achieve full density. The graphite mold serves as the vessel that applies this force.

It transmits uniaxial pressure—often reaching tens of megapascals—directly to the powder compact.

The mold’s high-temperature mechanical strength ensures it does not deform under this load, forcing the ceramic particles to undergo plastic flow. This physical rearrangement helps eliminate voids and promotes diffusion between particles.

3. Ensuring Thermal Uniformity

Achieving a homogenous microstructure in ceramics requires uniform temperature distribution.

High-strength graphite possesses excellent thermal conductivity. As the mold generates heat, it also distributes it evenly across the sample surface.

This prevents thermal gradients that could lead to cracking or uneven densification in the final Al2O3-TiC tool blank.

4. Creating a Micro-Reducing Atmosphere

Graphite naturally reacts with residual oxygen at high temperatures to create a localized reducing environment (CO/CO2).

For Al2O3-TiC sintering, this is beneficial. It helps protect the ceramic components—specifically the Titanium Carbide (TiC)—from oxidation during the high-temperature phases of the process.

Understanding the Trade-offs

While high-purity graphite is the standard for SPS, it introduces specific limitations that must be managed to ensure success.

Mechanical Strength Limits

Despite its high-temperature resilience, graphite is brittle. If the axial pressure exceeds the material's compressive strength limit, the mold will fracture catastrophically.

This sets a hard ceiling on the maximum pressure you can apply to the Al2O3-TiC sample, which effectively limits the maximum theoretical density achievable through pressure alone.

Chemical Reactivity

While the reducing atmosphere is generally helpful, graphite can react with certain materials at extreme temperatures.

Although Al2O3-TiC is relatively stable in graphite, direct contact at temperatures exceeding 1600°C can occasionally lead to surface carburization or unwanted interface reactions, requiring post-process machining or grinding.

Making the Right Choice for Your Goal

To maximize the effectiveness of the graphite mold during the Al2O3-TiC sintering process, align your operational parameters with the mold's capabilities.

- If your primary focus is Maximum Density: Ensure your mold design (wall thickness) is sufficient to withstand the maximum axial pressure required to induce plastic flow without fracturing.

- If your primary focus is Microstructural Homogeneity: Prioritize high-density graphite grades with superior thermal conductivity to ensure the rapid heating does not create thermal shock or uneven grain growth.

Ultimately, the graphite mold is the critical interface that translates electrical energy and mechanical force into the physical consolidation of your ceramic composite.

Summary Table:

| Role | Functional Mechanism | Benefit for Al2O3-TiC |

|---|---|---|

| Heating Element | Joule heating via electrical conductivity | Rapid heating rates & minimized grain growth |

| Pressure Vessel | Transmission of uniaxial pressure | Facilitates plastic flow and eliminates voids |

| Thermal Conductor | High thermal conductivity | Ensures uniform temperature and prevents cracking |

| Atmosphere Agent | Formation of CO/CO2 reducing environment | Protects TiC particles from oxidation |

Elevate Your Ceramic Sintering Precision with KINTEK

Achieving the perfect density and microstructure in Al2O3-TiC composites requires more than just high temperatures—it demands the right thermal and mechanical environment. KINTEK provides high-performance lab solutions backed by expert R&D and precision manufacturing.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature furnaces are fully customizable to meet your unique SPS and material research requirements.

Ready to optimize your sintering results? Contact our technical experts today to discover how our tailored equipment can bring superior durability and efficiency to your laboratory.

Visual Guide

References

- Zara Cherkezova‐Zheleva, Radu Robert Piticescu. Green and Sustainable Rare Earth Element Recycling and Reuse from End-of-Life Permanent Magnets. DOI: 10.3390/met14060658

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Spark Plasma Sintering SPS Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How do cooling modules in high-temperature laboratory furnaces manage thermal energy? Protect Your System Components

- Can alumina ceramic furnace tubes be reused? Maximize Cost Savings and Safety

- What is the purpose of an ultrasonic cleaner in NiMo@Cx catalyst prep? Achieve Uniform Slurry & High-Porosity Coatings

- Why is a sealing lid necessary for the clay-graphite crucible? Key to Successful Fe3O4/C Composite Synthesis

- What is the function of a Teflon-lined stainless steel autoclave in the hydrothermal synthesis of Bi2O3 precursors?

- How do sealed boxes and backfill materials function during high-temperature powder metallurgy sintering?

- Why is the precise regulation of oxygen ratios via mass flow controllers critical for MCTV catalyst yield?

- Are alumina ceramic furnace tubes suitable for high-pressure applications? Discover Key Factors for Safe Use