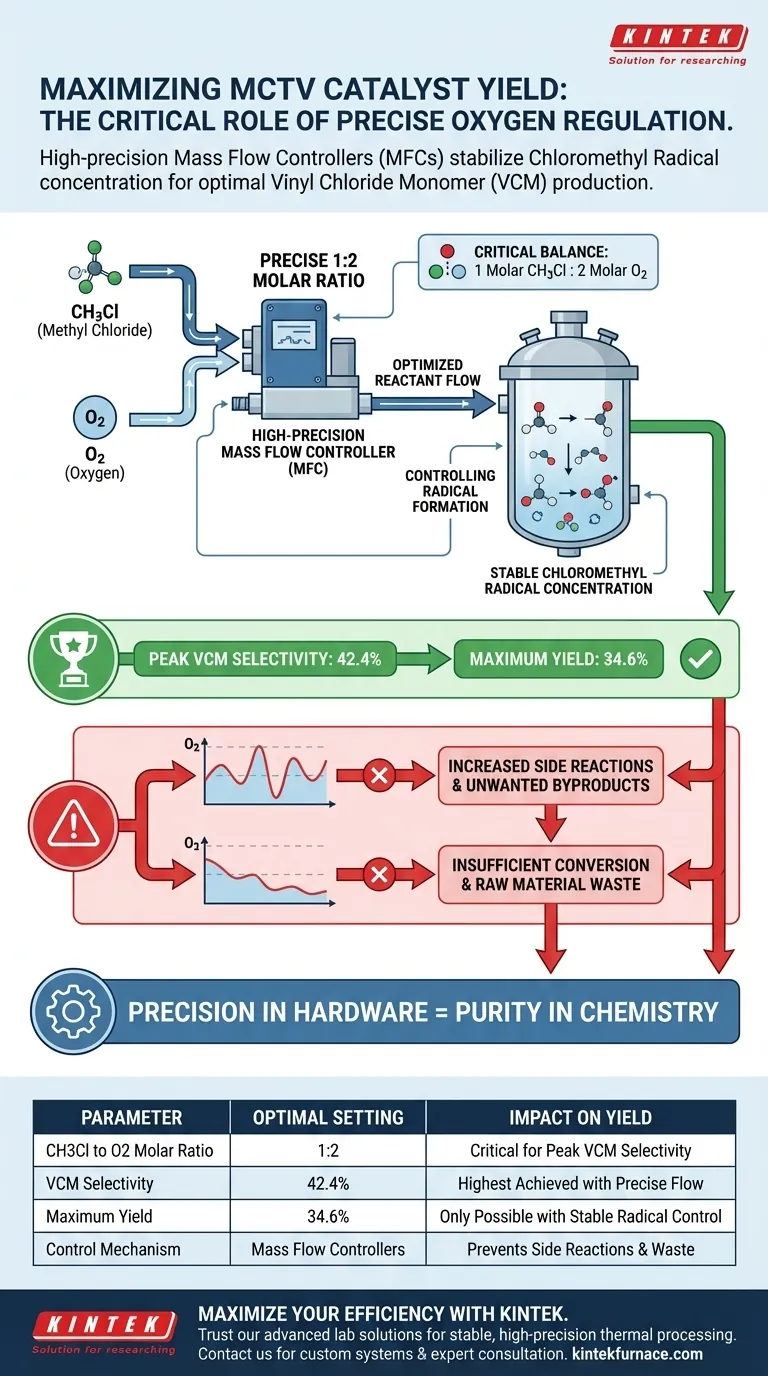

Precise oxygen regulation determines the specific chemical pathway taken during the autothermal cracking of methyl chloride. High-precision mass flow controllers are critical because they stabilize the concentration of chloromethyl radicals, ensuring the reaction stays within the narrow window required for maximum catalyst yield.

The balance of oxygen directly dictates the formation of chloromethyl radicals. Sustaining an exact 1:2 molar ratio is the only way to achieve peak VCM selectivity and the maximum yield of 34.6%.

The Chemistry of Flow Control

Controlling Radical Formation

In this specific reaction, oxygen acts as more than just a reactant; it is a regulator.

The oxygen content directly influences the concentration of chloromethyl radicals.

By strictly controlling the oxygen flow, you are effectively throttling the radical generation mechanism to the precise level needed for the target reaction.

The Critical 1:2 Ratio

Research indicates that a specific molar ratio of Methyl Chloride (CH3Cl) to Oxygen (O2) is required for optimal performance.

That optimal balance is a 1:2 molar ratio.

High-precision mass flow controllers are the only reliable method to maintain this exact stoichiometric balance continuously.

Impact on Selectivity and Yield

When this specific ratio is held constant, the process achieves a peak VCM (Vinyl Chloride Monomer) selectivity of 42.4%.

This high selectivity is the driving force behind achieving the maximum possible yield of 34.6%.

Understanding the Consequences of Deviation

The Risk of Side Reactions

If the mass flow controller allows the oxygen ratio to fluctuate, the chemical pathway shifts.

Deviations in oxygen flow frequently lead to increased side reactions, producing unwanted byproducts instead of the desired VCM.

Insufficient Conversion

Conversely, failing to maintain the precise flow rate can result in insufficient conversion.

This means a significant portion of the raw methyl chloride remains unreacted, lowering overall efficiency and yield.

Making the Right Choice for Your Goal

To maximize the efficiency of your MCTV catalyst process, you must prioritize fluid control stability.

- If your primary focus is maximizing product yield: Ensure your control system targets and rigidly holds the CH3Cl/O2 molar ratio at exactly 1:2 to reach the 34.6% yield cap.

- If your primary focus is process efficiency: Invest in high-precision mass flow controllers to mitigate the risk of side reactions and raw material waste caused by flow fluctuations.

Precision in your hardware directly translates to purity in your chemistry.

Summary Table:

| Parameter | Optimal Setting/Value | Impact on MCTV Yield |

|---|---|---|

| CH3Cl to O2 Molar Ratio | 1:2 | Critical for peak VCM selectivity |

| VCM Selectivity | 42.4% | Highest achieved under precise flow |

| Maximum Yield | 34.6% | Only possible with stable radical control |

| Control Mechanism | Mass Flow Controllers | Prevents side reactions and waste |

Maximize Your Chemical Process Efficiency with KINTEK

Precision in your equipment directly translates to purity in your results. Whether you are scaling up VCM production or conducting sensitive material research, KINTEK provides the advanced technology needed to maintain exact reaction environments.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of high-precision thermal processing. Don't let flow fluctuations compromise your yield—trust our high-temp lab solutions to deliver the stability your chemistry requires.

Ready to optimize your yield? Contact KINTEK today for expert consultation and customized solutions.

Visual Guide

References

- Nan Lü, Jie Fan. Geometric Matching Effect Induced High Dispersion of Na2WO4 Nanocluster on Cristobalite Support for Efficient Methyl Chloride-to-Vinyl Chloride Conversion. DOI: 10.3390/catal15040382

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- What is the necessity of configuring non-contact infrared pyrometers for temperature monitoring? Ensure Sintering Precision

- What are the key characteristics of the alumina furnace tube? Essential for High-Temp Lab Success

- Why is a high vacuum pumping system necessary during the preparation of Sb2S3? Ensure High-Purity Semiconductor Films

- How does a sealed high-purity graphite reaction box function? Optimize Sb-Ge Thin Film Selenization

- What is the purpose of a laboratory vacuum system in photocatalytic hydrogen evolution? Ensure Accurate Data Results

- Why is an alumina crucible necessary for g-C3N4 synthesis? Ensure High Purity & Stability in Polycondensation

- Why is a laboratory-grade high-pressure reactor essential for TiO2 nanoparticles? Optimize Purity and Efficiency

- Why is a laboratory vacuum drying oven utilized for recovered carbon black? Preserve rCB Integrity and Pore Structure