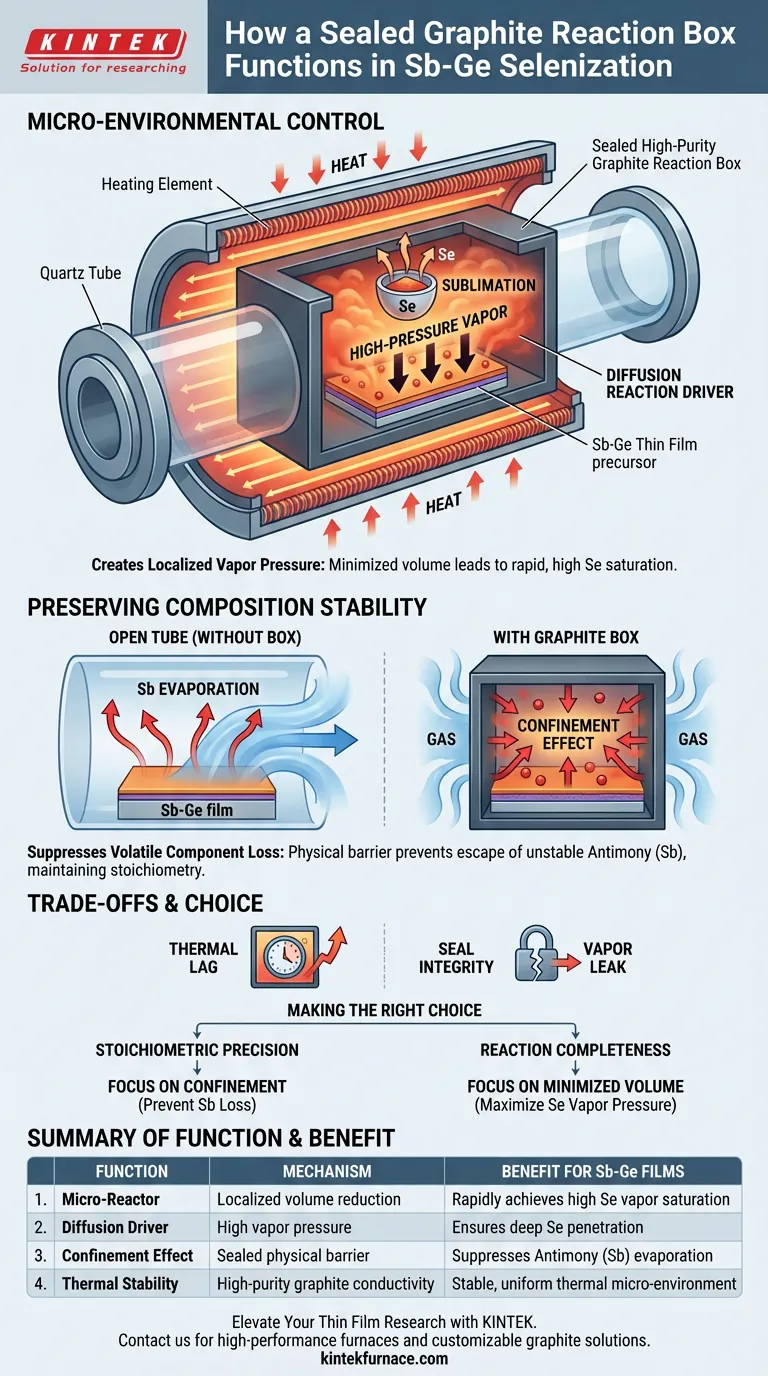

A sealed high-purity graphite reaction box acts as a localized micro-reactor within the larger tube furnace, specifically designed to regulate vapor pressure during the selenization of Sb-Ge thin films. By mechanically isolating the precursor and solid selenium source, the box creates a confined high-pressure zone that forces selenium diffusion while physically blocking the escape of volatile elements.

The graphite box utilizes a physical confinement effect to solve the primary challenge of Sb-Ge selenization: maintaining high selenium saturation for reaction while simultaneously preventing the thermal evaporation of unstable antimony components.

The Mechanics of Micro-Environmental Control

Creating Localized Vapor Pressure

The volume of a standard tube furnace is too large to easily saturate with selenium vapor using only a small solid source.

The graphite box reduces the effective volume of the reaction zone significantly. Upon heating, the solid elemental selenium (Se) sublimates, rapidly creating a high-concentration local selenium vapor pressure inside the box that is far denser than what would be possible in an open tube.

Facilitating the Diffusion Reaction

For the Sb-Ge precursor to properly selenize, selenium atoms must penetrate deep into the metallic layers.

The high vapor pressure generated by the box acts as a driving force. It promotes the diffusion reaction, ensuring that selenium atoms are effectively pushed into the Sb-Ge structure to form the desired compound.

Preserving Composition Stability

The Confinement Effect

At the high temperatures required for selenization, thin films are vulnerable to decomposition.

The sealed nature of the graphite box creates a confinement effect. By limiting the volume of gas that can escape, the box establishes a quasi-equilibrium state that stabilizes the film during the reaction.

Suppressing Volatile Component Loss

Antimony (Sb) is particularly volatile and prone to evaporating out of the film structure when heated.

Without the box, the Sb would likely escape into the continuous gas flow of the tube furnace, altering the film's stoichiometry. The graphite box suppresses the loss of volatile components, ensuring the final thin film retains the correct Sb-Ge ratio.

Understanding the Trade-offs

Thermal Lag Considerations

While graphite is an excellent conductor, introducing a physical box adds thermal mass to the system.

You must account for a slight delay between the furnace's set temperature and the actual temperature inside the box. The reaction environment inside requires time to reach thermal equilibrium with the heating elements outside.

Dependency on Seal Integrity

The entire mechanism relies on the "sealed" nature of the box to maintain vapor pressure.

If the fit of the graphite box is poor or the seal is compromised, the local vapor pressure will drop, leading to incomplete selenization and the potential loss of antimony.

Making the Right Choice for Your Goal

To maximize the quality of your Sb-Ge thin films, consider how the graphite box aligns with your specific processing objectives:

- If your primary focus is Stoichiometric Precision: Rely on the confinement effect of the box to prevent antimony evaporation and maintain the exact Sb-to-Ge ratio of your precursor.

- If your primary focus is Reaction Completeness: Utilize the minimized volume of the box to maximize selenium vapor pressure, driving the reaction deeper into the film layers.

By controlling the micro-environment, the graphite box transforms a standard heating process into a precise chemical deposition system.

Summary Table:

| Function | Mechanism | Benefit for Sb-Ge Films |

|---|---|---|

| Micro-Reactor | Localized volume reduction | Rapidly achieves high Se vapor saturation |

| Diffusion Driver | High vapor pressure | Ensures deep Se penetration into precursor layers |

| Confinement Effect | Sealed physical barrier | Suppresses evaporation of volatile Antimony (Sb) |

| Thermal Stability | High-purity graphite conductivity | Provides a stable, uniform thermal micro-environment |

Elevate Your Thin Film Research with KINTEK

Precision in selenization requires more than just heat—it requires a perfectly controlled micro-environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Vacuum, and CVD systems, along with customizable high-purity graphite solutions designed for your unique material needs. Whether you are suppressing volatile component loss or maximizing reaction completeness, our lab high-temp furnaces provide the stability your research demands.

Ready to optimize your stoichiometry? Contact KINTEK today to discuss our customizable furnace solutions.

Visual Guide

References

- Growth and Properties of Sb‐Ge‐Se Thin Films: A Promising Material for Sustainable Photovoltaic Devices Development. DOI: 10.1002/eem2.70059

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What role does a high-precision mass flow controller play in assessing the gas selectivity of Gallium Sulfide sensors?

- What is the purpose of a water-cooling jacket in a methane cracking reactor? Prevent Blockages & Thermal Damage

- How does the design of high-purity alumina capillaries influence bubble formation? Optimize Surface Tension Accuracy

- What is the function of vacuum-sealed quartz jackets in sample encapsulation? Ensure Purity in Material Synthesis

- Why is a high vacuum pumping system necessary during the preparation of Sb2S3? Ensure High-Purity Semiconductor Films

- What is the function of a high-precision constant temperature oven in LIG composite curing? Achieve Perfect Stability

- Why is a high-purity graphite box required for CZTS sulfurization? Protect Thin Film Integrity and Crystallinity

- What is the purpose of using an insulating layer in CCCM thermal conductivity tests? Ensuring 1D Heat Flow Accuracy