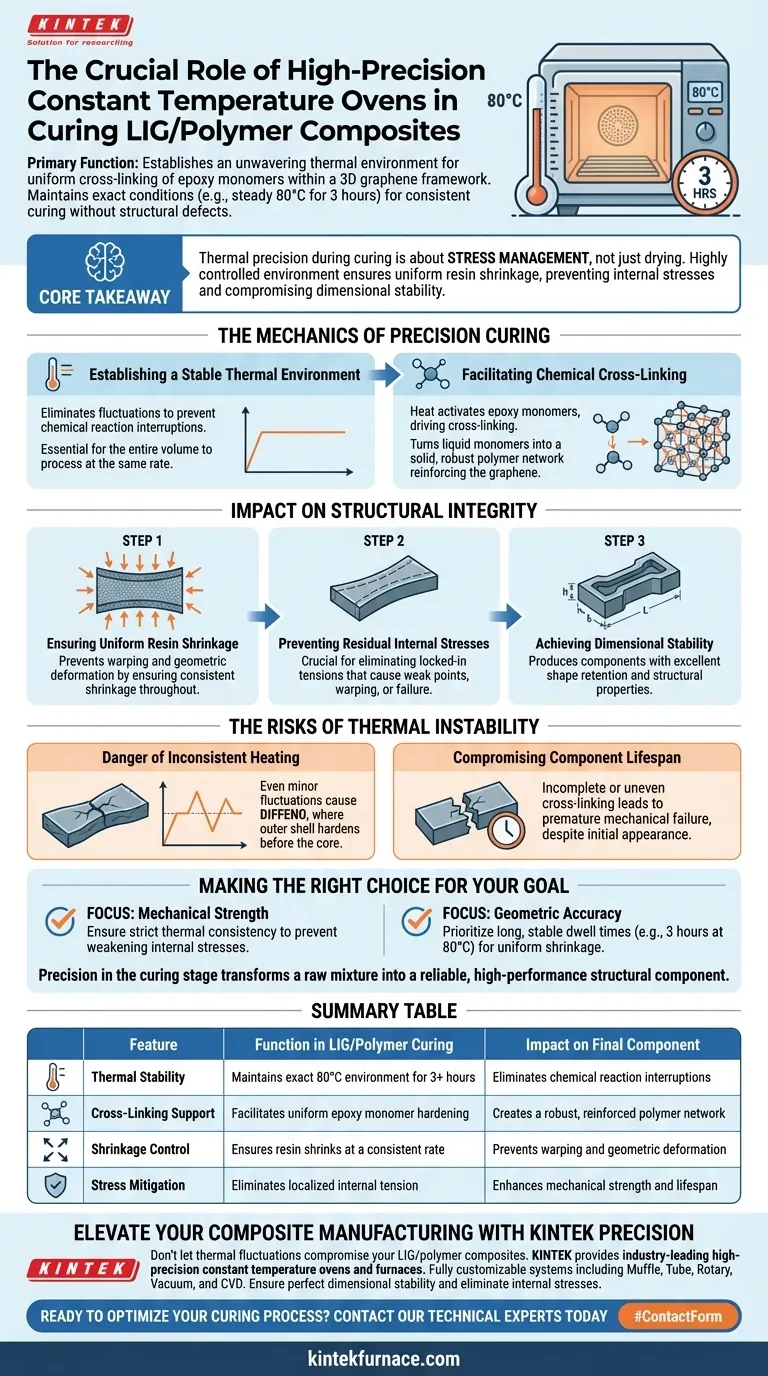

The primary function of a high-precision constant temperature oven is to establish an unwavering thermal environment required to facilitate the uniform cross-linking of epoxy monomers within a 3D graphene framework. By maintaining exact conditions—such as a steady 80 degrees Celsius for 3 hours—this equipment ensures the polymer matrix cures consistently without introducing structural defects.

Core Takeaway Thermal precision during curing is less about "drying" and more about stress management. A highly controlled environment ensures uniform resin shrinkage, which is the only way to prevent internal stresses that would otherwise compromise the dimensional stability and strength of the final component.

The Mechanics of Precision Curing

Establishing a Stable Thermal Environment

The curing process for Laser-Induced Graphene (LIG)/polymer composites requires more than just heat; it requires thermal stability. A high-precision oven eliminates temperature fluctuations that could interrupt the chemical reaction.

For example, maintaining a constant 80°C for a duration of 3 hours allows the material to reach a steady state. This consistency is vital for the entire volume of the composite to process at the same rate.

Facilitating Chemical Cross-Linking

Inside the oven, the heat activates the epoxy monomers infused within the 3D graphene framework.

The constant temperature drives the cross-linking process, effectively hardening the resin. This turns the liquid monomers into a solid, robust polymer network that reinforces the graphene structure.

Impact on Structural Integrity

Ensuring Uniform Resin Shrinkage

As polymers cure, they naturally shrink. If the temperature varies across the oven or fluctuates over time, different parts of the composite will shrink at different rates.

A high-precision oven ensures that this shrinkage occurs uniformly throughout the entire component. This uniformity is the difference between a flat, usable part and a warped, defective one.

Preventing Residual Internal Stresses

The most critical function of controlled thermal processing is the prevention of residual internal stresses.

When curing is uneven, internal tension builds up inside the material. These locked-in stresses are invisible weak points that can lead to immediate warping or eventual failure under load.

Achieving Dimensional Stability

By eliminating internal stress and ensuring uniform shrinkage, the oven produces components with excellent dimensional stability. The final part retains its intended shape and structural properties, resulting in a high-performance structural component.

The Risks of Thermal Instability

The Danger of Inconsistent Heating

Using standard heating equipment lacks the precision required for high-performance composites. Even minor fluctuations can cause differential curing, where the outer shell hardens before the core.

Compromising Component Lifespan

If the curing stage is rushed or unstable, the resulting cross-linking may be incomplete or uneven. While the part may look correct initially, the lack of a uniform internal structure often leads to premature mechanical failure.

Making the Right Choice for Your Goal

When setting up your manufacturing process for LIG/polymer composites, consider your specific performance requirements.

- If your primary focus is mechanical strength: Ensure your oven maintains strict thermal consistency to prevent internal stresses that weaken the material.

- If your primary focus is geometric accuracy: Prioritize long, stable dwell times (e.g., 3 hours at 80°C) to guarantee uniform shrinkage and dimensional stability.

Precision in the curing stage is the defining factor that transforms a raw mixture into a reliable, high-performance structural component.

Summary Table:

| Feature | Function in LIG/Polymer Curing | Impact on Final Component |

|---|---|---|

| Thermal Stability | Maintains exact 80°C environment for 3+ hours | Eliminates chemical reaction interruptions |

| Cross-Linking Support | Facilitates uniform epoxy monomer hardening | Creates a robust, reinforced polymer network |

| Shrinkage Control | Ensures resin shrinks at a consistent rate | Prevents warping and geometric deformation |

| Stress Mitigation | Eliminates localized internal tension | Enhances mechanical strength and lifespan |

Elevate Your Composite Manufacturing with KINTEK Precision

Don't let thermal fluctuations compromise the structural integrity of your LIG/polymer composites. KINTEK provides industry-leading high-precision constant temperature ovens and laboratory high-temp furnaces designed for the rigorous demands of advanced material science.

Backed by expert R&D and manufacturing, our systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—are fully customizable to meet your unique research or production needs. Ensure perfect dimensional stability and eliminate internal stresses with equipment built for accuracy.

Ready to optimize your curing process? Contact our technical experts today to find the ideal thermal solution for your lab.

Visual Guide

References

- Laser‐Induced 3D Graphene Enabled Polymer Composites with Improved Mechanical and Electrical Properties Toward Multifunctional Performance. DOI: 10.1002/advs.202509039

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a copper mold play in the formation of glass samples? Master Rapid Quenching & Amorphous Solidification

- What are tube furnace tubes made of? Select the Right Material for Your Process

- Why are Type K thermocouples preferred in industrial furnaces? Unlock Reliable Precision for High-Heat Control

- How does a PID temperature controller facilitate gasification research? Unlock Precision in Industrial Simulations

- Why are long alumina boats selected as sample containers for zone refining experiments? Optimize Material Purification

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis

- Why are alumina ceramic tubes preferred for high-temperature furnaces? Ensure Stability and Control Up to 1800°C