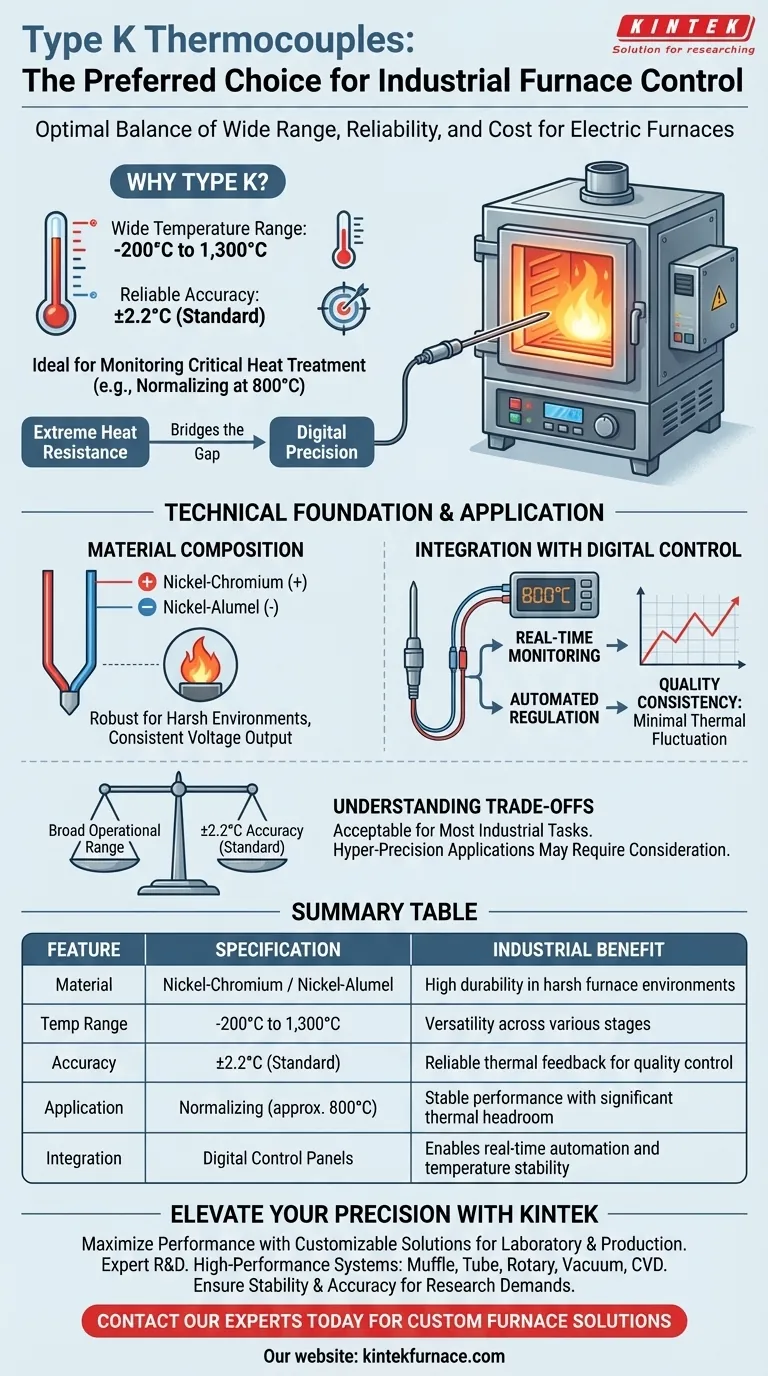

Type K thermocouples are the preferred choice for industrial electric furnace control because they offer an optimal balance of wide temperature range and reliable accuracy. Composed of Nickel-Chromium and Nickel-Alumel, these sensors operate effectively from -200°C to 1,300°C. This specific range, combined with a standard accuracy of ±2.2°C, makes them ideal for monitoring critical heat treatment processes where consistent thermal feedback is mandatory.

By bridging the gap between extreme heat resistance and digital precision, Type K thermocouples allow operators to maintain strict quality control during sensitive normalizing processes at temperatures as high as 800°C.

The Technical Foundation

Material Composition

The reliability of the Type K thermocouple stems from its specific metallurgical construction. It utilizes a Nickel-Chromium positive leg and a Nickel-Alumel negative leg.

This combination is robust enough to withstand the harsh environments found inside industrial electric furnaces while generating a consistent voltage output for measurement.

Broad Operational Range

Industrial furnaces require sensors that do not fail under thermal stress. The Type K offers a measurement spectrum spanning from -200°C to 1,300°C.

This wide versatility ensures that a single sensor type can handle various stages of operation, from cryogenic baselines up to the intense heat required for metal treatment.

Application in Process Control

Optimization for Normalizing

Heat treatment processes, such as normalizing, often require sustained temperatures around 800°C.

The Type K thermocouple operates comfortably within this range, well below its upper limit of 1,300°C. This "headroom" ensures the sensor remains stable and durable even during prolonged heating cycles.

Integration with Digital Control

Modern electric furnaces rely on digital control panels to automate temperature regulation.

Type K sensors provide the necessary electrical feedback to these panels. This integration allows the system to monitor internal conditions in real-time.

Ensuring Quality Consistency

The primary goal of the control system is consistent heat treatment quality.

By providing continuous feedback, the thermocouple allows the digital controller to make immediate adjustments to the heating elements. This minimizes thermal fluctuation and ensures the workload is processed exactly according to specification.

Understanding the Trade-offs

Accuracy Limitations

While highly effective for general industrial use, operators must be aware of the accuracy specifications. The Type K thermocouple typically offers an accuracy of ±2.2°C.

For most normalizing and heat treatment tasks, this tolerance is perfectly acceptable. However, for applications requiring hyper-precision (e.g., fractional degree control), this tolerance band must be accounted for in the quality assurance strategy.

Making the Right Choice for Your Goal

To ensure your furnace control system meets your operational requirements, consider the following:

- If your primary focus is Standard Heat Treatment: Rely on Type K thermocouples for processes like normalizing at 800°C, where the sensor's durability and range provide the best return on investment.

- If your primary focus is Process Stability: Utilize the real-time feedback capabilities of these sensors to drive digital logic, ensuring your furnace reacts instantly to any temperature deviation.

Selecting the Type K thermocouple ensures a robust link between the physical heat of the furnace and the digital precision of your control system.

Summary Table:

| Feature | Specification | Industrial Benefit |

|---|---|---|

| Material | Nickel-Chromium / Nickel-Alumel | High durability in harsh furnace environments |

| Temp Range | -200°C to 1,300°C | Versatility across various heat treatment stages |

| Accuracy | ±2.2°C (Standard) | Reliable thermal feedback for quality control |

| Application | Normalizing (approx. 800°C) | Stable performance with significant thermal headroom |

| Integration | Digital Control Panels | Enables real-time automation and temperature stability |

Elevate Your Heat Treatment Precision with KINTEK

Maximize your furnace performance with temperature control solutions designed for industrial excellence. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or production needs.

Whether you are performing sensitive normalizing at 800°C or high-temperature material synthesis, our systems ensure the stability and accuracy your research demands. Contact our technical experts today to discuss how our customizable high-temp furnaces can optimize your workflow.

Visual Guide

References

- Gustavo Ribeiro Zanini, LUIS CARLOS GERON. PROJETO DE UM FORNO ELÉTRICO INDUSTRIAL PARA TRATAMENTO TÉRMICO TUBOS DE AÇO SA-178 GR A. DOI: 10.52138/citec.v17i01.437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a vacuum pump necessary for bio-adsorbent performance assessments? Ensuring Industrial Viability in VSA

- Why is a precision constant temperature drying oven required for BZT ceramic powders? Ensure Perfect Powder Quality

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the key characteristics of the alumina furnace tube? Essential for High-Temp Lab Success

- Why are high-temperature ceramic crucibles used for chalcopyrite? Ensure Purity in Ore Thermal Treatment

- How does the sealed Alumina Tube structure benefit the design of a reference electrode? Boost Electrolysis Precision