The use of vacuum-sealed quartz tubes is a non-negotiable requirement for preserving the structural integrity of Titanium-Copper alloys. Because titanium is highly reactive at elevated temperatures, exposing the bare alloy to the atmosphere triggers immediate degradation. Encapsulating the material creates an isolated environment that prevents chemical contamination during the rigorous heating cycles required for homogenization.

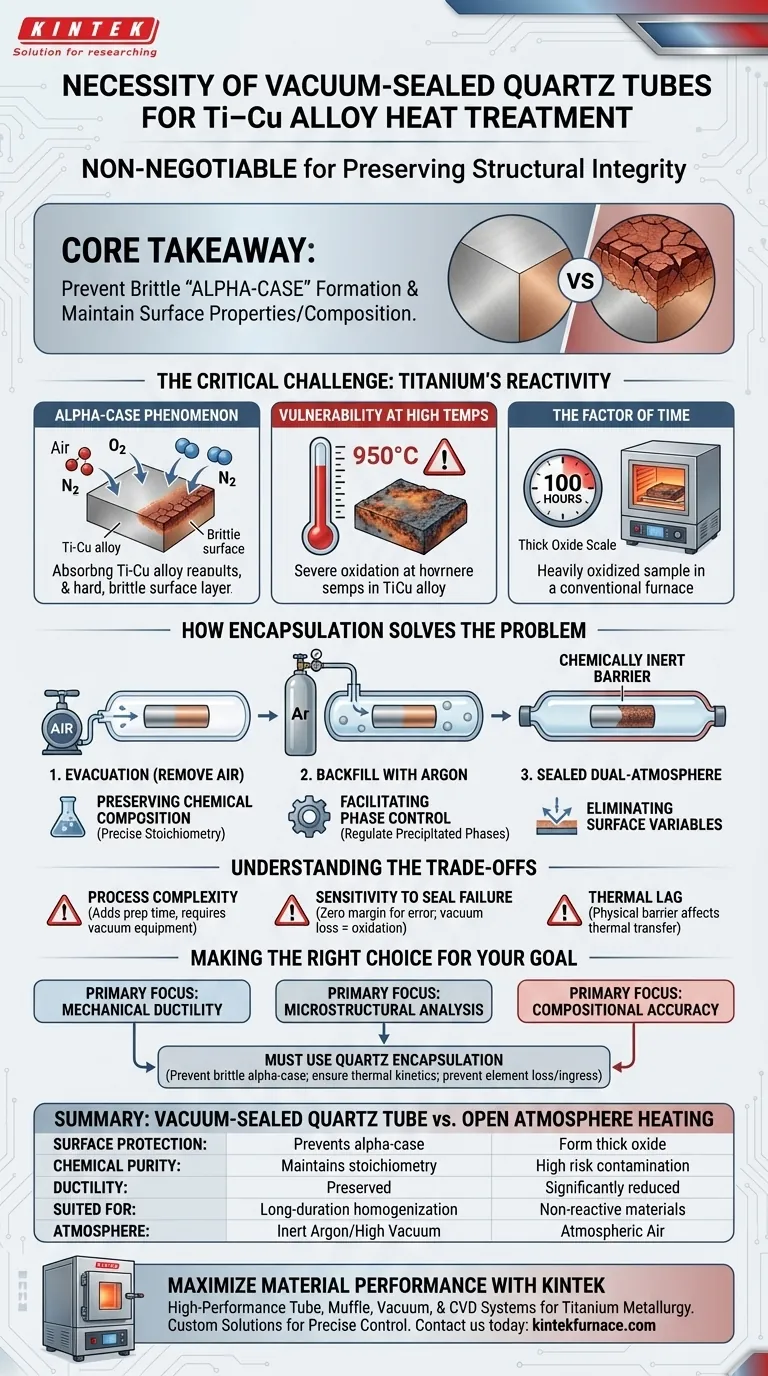

Core Takeaway The primary function of the quartz tube is to prevent the formation of a hard, brittle "alpha-case" layer caused by the alloy's rapid reaction with oxygen and nitrogen. By maintaining a controlled vacuum or argon atmosphere, the tube safeguards the alloy's surface properties and chemical composition throughout extended heat treatments.

The Critical Challenge: Titanium's Reactivity

The Alpha-Case Phenomenon

Titanium alloys possess a high chemical affinity for interstitial elements found in air, specifically oxygen and nitrogen. When heated, the alloy absorbs these elements, creating an oxygen-enriched surface layer known as the "alpha-case." This layer is characteristically hard and brittle, which severely compromises the mechanical ductility of the material.

Vulnerability at High Temperatures

The risk of oxidation increases drastically as temperatures rise. Heat treatment processes for Titanium-Copper alloys often occur at roughly 950°C. Without protection, the material would suffer catastrophic surface degradation during these high-thermal states.

The Factor of Time

Homogenization processes are not brief; they can last up to 100 hours. A sample exposed to impurities in a conventional furnace for this duration would develop a thick oxide scale. The quartz tube maintains the sample's purity over these long durations.

How Encapsulation Solves the Problem

Dual-Atmosphere Protection

The quartz tubes utilize a specific preparation method to ensure maximum protection. They are first evacuated to remove air and then backfilled with argon gas. This creates a "dual-atmosphere" barrier that is chemically inert regarding the titanium alloy.

Preserving Chemical Composition

Beyond preventing surface oxides, sealing the environment ensures that the alloy's chemical makeup remains precise. In open-air furnaces, volatile elements can be lost, or contaminants gained. The sealed tube ensures the final microstructure reflects the intended stoichiometry of the Titanium-Copper blend.

Facilitating Phase Control

Precise heat treatment is required to trigger solid-state phase transformations, such as the precipitation of Ti2Cu. By eliminating surface variables and oxidation, the thermal input acts solely on the internal microstructure. This allows researchers to accurately regulate the size and distribution of precipitated phases.

Understanding the Trade-offs

Process Complexity

Using quartz tubes adds significant preparation time compared to standard atmospheric heating. Each sample must be individually encapsulated, evacuated, and sealed. This reduces throughput and requires specialized vacuum equipment.

Sensitivity to Seal Failure

The entire protection mechanism relies on the integrity of the quartz seal. If a micro-crack develops or the seal is imperfect, the vacuum is lost, and the sample will oxidize essentially as if it were in an open furnace. There is zero margin for error in the sealing process.

Thermal Lag

While quartz is heat-resistant, placing a sample inside a tube introduces a physical barrier between the heat source and the metal. While tube furnaces provide precise control, operators must account for the slight difference in thermal transfer compared to direct exposure.

Making the Right Choice for Your Goal

To ensure your Titanium-Copper heat treatment yields valid results, align your approach with your specific objectives:

- If your primary focus is Mechanical Ductility: You must use quartz encapsulation to prevent the formation of the brittle alpha-case layer that causes premature fracture.

- If your primary focus is Microstructural Analysis: You must use quartz encapsulation to ensure the phases you observe are a result of thermal kinetics, not atmospheric contamination.

- If your primary focus is Compositional Accuracy: You must use quartz encapsulation to prevent the loss of metallic elements or the ingress of oxygen and nitrogen.

Ultimately, vacuum-sealed quartz tubes are not an optional accessory, but a fundamental prerequisite for obtaining reliable data and usable materials in Titanium-Copper metallurgy.

Summary Table:

| Feature | Vacuum-Sealed Quartz Tube | Open Atmosphere Heating |

|---|---|---|

| Surface Protection | Prevents brittle alpha-case layer | Formation of thick, hard oxide scale |

| Chemical Purity | Maintains intended stoichiometry | High risk of O₂ and N₂ contamination |

| Ductility | Preserved mechanical properties | Significantly reduced due to brittleness |

| Suited For | Long-duration homogenization | Non-reactive materials only |

| Atmosphere | Inert Argon or High Vacuum | Atmospheric air |

Maximize Your Material Performance with KINTEK

Don't let atmospheric contamination compromise your R&D results. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Vacuum, and CVD systems, specifically designed to handle the rigorous demands of titanium metallurgy and other advanced lab high-temp processes. Our furnaces are fully customizable to your unique research needs, ensuring precise phase control and structural integrity for every sample.

Ready to elevate your heat treatment precision? Contact us today to find your custom furnace solution!

Visual Guide

References

- Daisy Rabbitt. Antimicrobial Titanium–Copper Alloys: The Role of Microstructure in Arc‐Melted Compositions. DOI: 10.1002/adem.202500347

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the purpose of configuring a hot gas filter within a Catalytic Hydropyrolysis (CHP) process? Ensure Reactor Life

- Is it possible to tailor high-temperature laboratory furnaces? Custom Engineering for Unique Research Needs

- What are the key characteristics of the alumina furnace tube? Essential for High-Temp Lab Success

- Why is the pore size of refractory materials significant? Unlocking Precision in Bubble Formation and Oxygen Impact

- What maintenance is required for a water circulating vacuum pump? Ensure Peak Performance and Longevity

- What is the function of the substrate heating system for WS2 thin films? Optimize Crystallinity and Adhesion

- What are the functions of BN crucibles and embedding powders in Si3N4 sintering? Expert Guide to Material Stability

- What role does a water saturator play in the physical activation of carbon materials? Unlock High-Performance Porosity