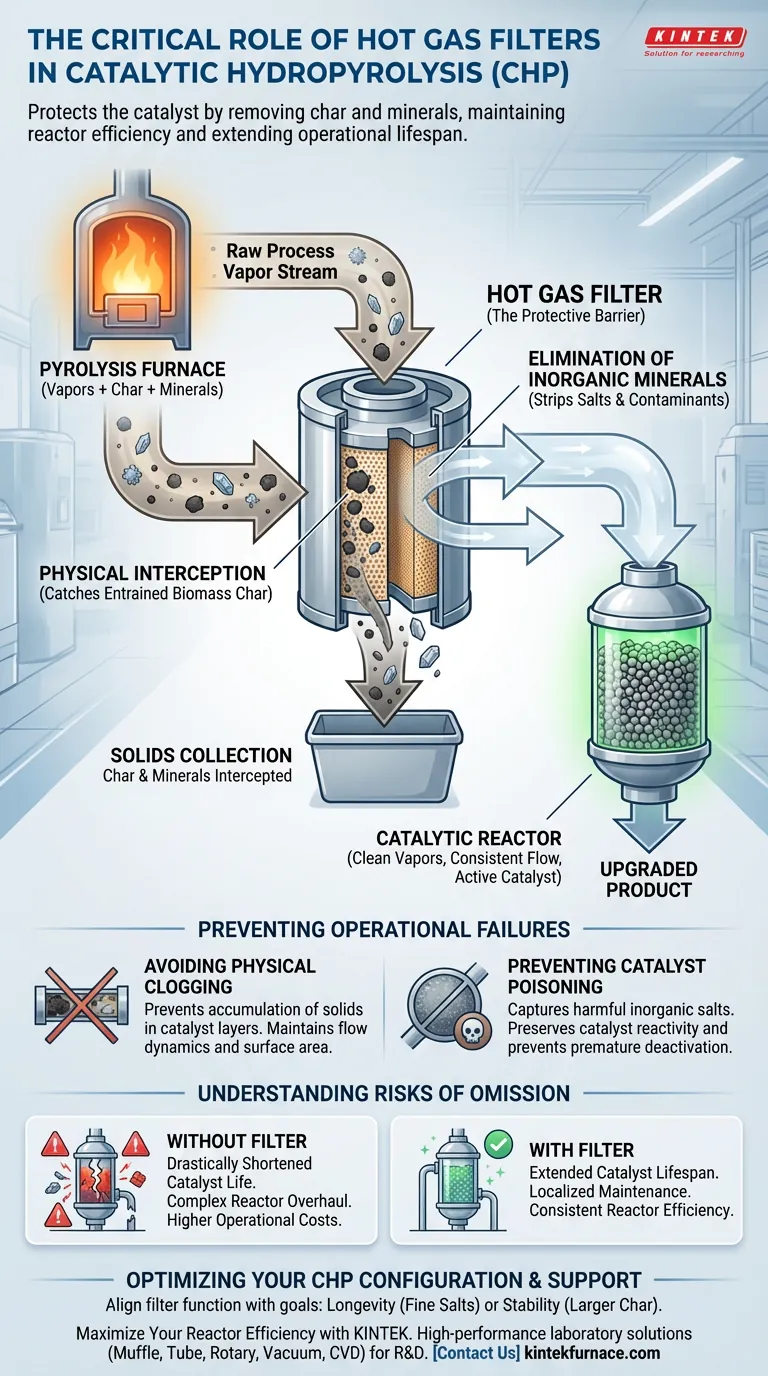

The strategic purpose of a hot gas filter in a Catalytic Hydropyrolysis (CHP) process is to act as a critical protective barrier between the pyrolysis furnace and the catalytic reactor. Its primary function is to physically intercept and remove entrained biomass char and inorganic minerals from the vapor stream before they can enter the catalyst bed.

Core Takeaway By stripping solid particles and inorganic salts from pyrolysis vapors, the hot gas filter prevents physical clogging and chemical poisoning of the catalyst. This component is essential for maintaining reactor efficiency and significantly extending the operational lifespan of the catalyst.

The Mechanics of Catalyst Protection

Physical Interception of Solids

During the pyrolysis process, the furnace generates vapors intended for upgrading. However, this process also produces solid byproducts, specifically entrained biomass char.

The hot gas filter is positioned directly after the furnace to catch these solids. This ensures that only the gaseous vapors proceed to the delicate downstream equipment.

Elimination of Inorganic Minerals

Biomass feedstocks naturally contain various inorganic minerals and salts. These materials are carried along with the process vapors and pose a significant threat to the chemical stability of the system.

The filter effectively separates these inorganic elements from the vapor. This separation is vital for the health of the chemical reaction that follows.

Preventing Operational Failures

Avoiding Physical Clogging

If solid particles are allowed to pass into the reactor, they accumulate within the catalyst layers. This buildup creates physical blockages that restrict flow and reduce the surface area available for reaction.

By removing these particles upstream, the filter maintains the structural integrity of the catalyst bed. This ensures consistent flow dynamics through the reactor.

Preventing Catalyst Poisoning

The inorganic salts present in biomass are chemically harmful to the catalyst. If they contact the active sites of the catalyst, they cause "poisoning," which permanently deactivates the material.

The hot gas filter mitigates this risk by capturing salts before they reach the reactor. This preserves the catalyst's reactivity and prevents premature failure.

Understanding the Risks of Omission

The Trade-off of Complexity vs. Longevity

Including a hot gas filter adds a step to the CHP process configuration. However, omitting this component exposes the reactor to immediate contamination risks.

Without this filtration, the system trades a simpler initial setup for a drastically shortened catalyst life. The operational cost of frequent catalyst replacement far outweighs the complexity of maintaining the filter.

Maintenance Focus Shift

The filter intentionally concentrates the waste material (char and minerals) in one location. This localizes maintenance efforts to the filter unit rather than the complex reactor bed.

Allowing contaminants to bypass this stage would disperse them throughout the reactor. This would transform a manageable cleaning task into a critical system overhaul.

Optimizing Your CHP Configuration

To ensure your Catalytic Hydropyrolysis process runs effectively, you must align the filter's function with your operational goals.

- If your primary focus is Equipment Longevity: Ensure the filter is rated to capture fine inorganic salts to prevent chemical poisoning of the catalyst.

- If your primary focus is Process Stability: Prioritize the removal of larger entrained char particles to prevent pressure buildup and physical clogging of the catalyst layers.

Implementing a robust hot gas filter is the single most effective mechanical step you can take to preserve the chemistry of your reactor.

Summary Table:

| Feature | Role in CHP Process | Impact on Catalyst |

|---|---|---|

| Physical Interception | Removes entrained biomass char and solids | Prevents bed clogging and flow restriction |

| Mineral Removal | Strips inorganic salts and minerals from vapor | Prevents chemical poisoning and deactivation |

| System Maintenance | Concentrates waste in one accessible location | Reduces reactor downtime and overhaul costs |

| Flow Optimization | Ensures clean vapor stream enters the reactor | Maintains consistent reaction surface area |

Maximize Your Reactor Efficiency with KINTEK

Don’t let contaminants compromise your research or production. KINTEK provides high-performance laboratory solutions backed by expert R&D and manufacturing. Our extensive range includes Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to meet the unique demands of your Catalytic Hydropyrolysis or high-temperature processes.

Protect your catalyst and streamline your operations today. Contact our specialists now to discuss your custom furnace needs.

Visual Guide

References

- Hoda Shafaghat, Olov Öhrman. Customized Atmospheric Catalytic Hydropyrolysis of Biomass to High-Quality Bio-Oil Suitable for Coprocessing in Refining Units. DOI: 10.1021/acs.energyfuels.3c05078

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a high-vacuum extraction system used to reach 10⁻² Pa inside composite billets? Ensure Superior Metal Bonding

- Why is a Mass Flow Controller (MFC) important for gas-phase corrosion research? Ensure Data Integrity & Precision

- Why is the selection of crucibles with specific internal linings necessary? Protect Purity in Superalloy Melting

- What is the role of an infrared pyrometer in wood carbonization? Optimize Your High-Temp Thermal Control

- What are the performance parameters of a circulating water vacuum pump? Optimize Your Lab's Vacuum Efficiency

- What are the different grades of Alumina ceramic and how do they differ? Choose the Right Grade for Your Needs

- How does a sealed high-purity graphite reaction box function? Optimize Sb-Ge Thin Film Selenization

- What is the purpose of a water-cooling jacket in a methane cracking reactor? Prevent Blockages & Thermal Damage