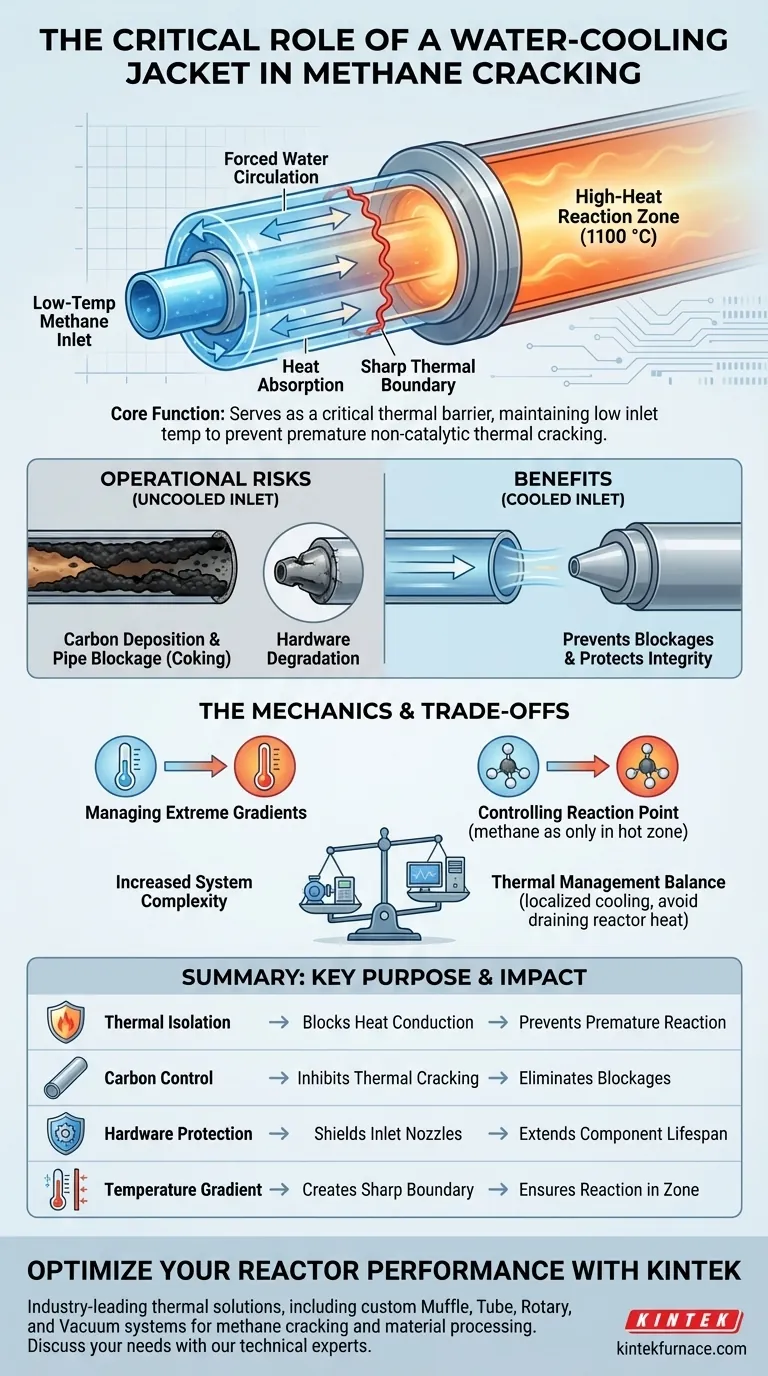

A water-cooling jacket serves as a critical thermal barrier within the gas inlet system. Its specific purpose is to maintain high-concentration methane at a low temperature immediately before it enters the high-heat reaction zone. This active cooling prevents the gas from reacting inside the delivery pipes, ensuring chemical breakdown occurs only where intended.

The core function of the water-cooling jacket is to prevent premature non-catalytic thermal cracking. By strictly isolating the inlet temperature from the 1100 °C reactor core, the system prevents solid carbon from accumulating in the feed lines, thereby avoiding catastrophic pipe blockages.

The Mechanics of Temperature Isolation

Managing Extreme Thermal Gradients

Methane cracking reactors operate at extremely high temperatures, often reaching 1100 °C in the reaction zone.

The gas inlet system connects physically to this zone, creating a direct path for heat to conduct backward into the supply lines.

The water-cooling jacket uses forced circulation to absorb this heat, creating a sharp thermal boundary that keeps the inlet piping cool despite its proximity to the reactor core.

Controlling the Reaction Point

Methane is chemically stable at lower temperatures but begins to break down (crack) as heat increases.

If the gas heats up gradually while moving through the inlet pipe, it will undergo non-catalytic thermal cracking before reaching the reactor.

The cooling jacket ensures the methane transitions from the cold inlet to the hot zone almost instantaneously, preventing undefined reactions in the transport phase.

Operational Risks of Uncooled Inlets

Preventing Carbon Deposition

When methane cracks prematurely inside the inlet piping, it releases solid carbon as a byproduct.

Without a cooling jacket, this carbon accumulates rapidly on the inner walls of the pipe, a process often referred to as coking or fouling.

This deposition restricts gas flow and eventually leads to complete pipe blockages, requiring system shutdown and complex maintenance.

Protecting Hardware Integrity

Beyond process chemistry, the inlet components themselves face physical risks from the reactor's heat.

Feedstock capillaries and nozzles are delicate components that can degrade or deform under prolonged exposure to extreme temperatures.

The water-cooling jacket acts as a shield, preserving the structural integrity of the inlet nozzle and extending the lifespan of these critical components.

Common Pitfalls and Trade-offs

Increased System Complexity

Implementing a water-cooling jacket introduces additional infrastructure to the reactor design.

Operators must manage coolant pumps, flow monitors, and leak detection systems, which adds a layer of mechanical complexity compared to a passive inlet.

Thermal Management Balance

While cooling is essential for the inlet, it introduces a "cold spot" near the reactor's "hot zone."

Designers must ensure the cooling effect is localized strictly to the inlet tip.

If the cooling is too aggressive or poorly insulated, it can drain heat from the reaction zone itself, reducing the overall thermal efficiency of the cracking process.

Ensuring Reactor Reliability

To maximize the efficiency and safety of your methane cracking operations, consider these priorities:

- If your primary focus is Process Continuity: Ensure the cooling jacket flow rate is sufficient to prevent any temperature rise in the inlet, as even minor heating can initiate carbon blockages.

- If your primary focus is Equipment Longevity: Monitor the outlet temperature of the cooling water to verify that the nozzle tip remains within its safe thermal operating limit.

Effective thermal isolation at the inlet is the single most important factor in preventing downtime caused by feed-line obstruction.

Summary Table:

| Feature | Purpose | Impact on Operations |

|---|---|---|

| Thermal Isolation | Blocks heat conduction from the 1100°C zone | Prevents premature gas reaction in feed lines |

| Carbon Control | Inhibits non-catalytic thermal cracking | Eliminates pipe blockages and costly coking |

| Hardware Protection | Shields inlet nozzles and capillaries | Extends lifespan of delicate reactor components |

| Temperature Gradient | Creates a sharp boundary at the inlet tip | Ensures reaction occurs only in the intended zone |

Optimize Your Reactor Performance with KINTEK

Don't let carbon deposition and thermal fatigue halt your production. KINTEK provides industry-leading thermal solutions, backed by expert R&D and manufacturing. Our extensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—along with fully customizable lab high-temp furnaces—are designed to meet your unique methane cracking and material processing needs.

Ready to enhance your lab's efficiency? Contact our technical experts today to discuss how our precision-engineered heating and cooling systems can maximize your uptime.

Visual Guide

References

- Roger Khalil, Øyvind Skreiberg. Catalytic Methane Decomposition for the Simultaneous Production of Hydrogen and Low-Reactivity Biocarbon for the Metallurgic Industry. DOI: 10.3390/en18030558

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role do high-purity graphite crucibles play in Boron Carbide sintering? Optimize Ceramic Purity and Density

- What is the function of a high-purity porcelain crucible? Expert Guide to Chromium-Doped Borosilicate Glass Preparation

- What is the primary function of graphitized quartz glass tubes in the synthesis of Bi2Se3-Nd2Se3 alloys?

- How does the dispersion of ruthenium precursors on alumina carriers affect thermal processing in a lab furnace?

- Why is the pore size of refractory materials significant? Unlocking Precision in Bubble Formation and Oxygen Impact

- What are the main reasons for the alumina furnace tube being prone to breaking? Prevent Costly Failures with Expert Tips

- Why are high-purity graphite crucibles with lids used for ilmenite reduction? Control Your Micro-Reducing Atmosphere

- Why are high-purity quartz reaction tubes utilized in CVD reactions for preparing Ni-Co doped carbon nanotubes?