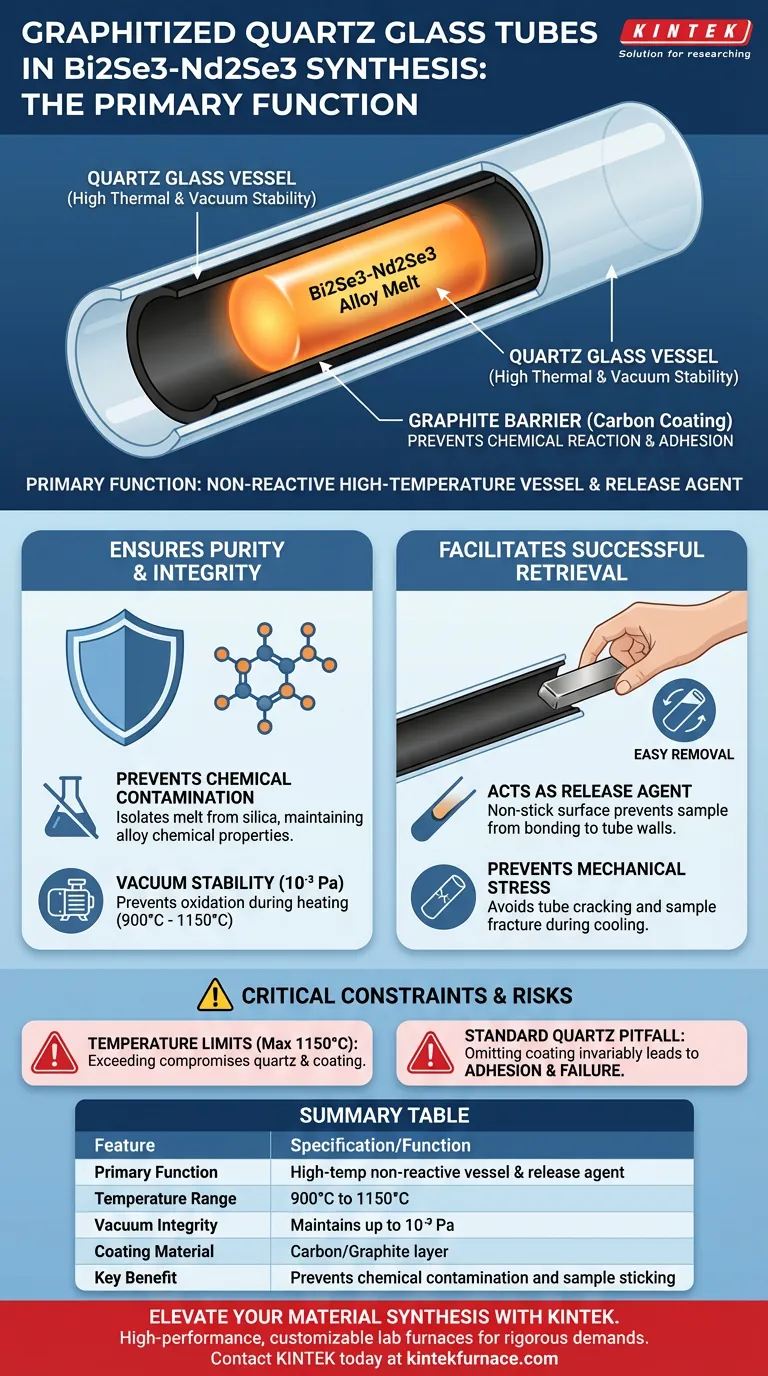

The primary function of graphitized quartz glass tubes in this context is to serve as a non-reactive, high-temperature vessel that prevents the synthesized alloy from bonding to the container. By coating the inner wall with carbon, the tube acts as a barrier that stops the metallic melt from chemically reacting with or adhering to the quartz, ensuring the final sample is pure and retrievable.

The graphitized coating is the critical interface that transforms a standard quartz tube into a viable synthesis vessel. It separates the reactive metallic melt from the silica glass, preserving both the chemical integrity of the alloy and the physical structure of the sample.

The Role of the Reaction Vessel

Thermal and Vacuum Stability

Synthesis of Bi2Se3-Nd2Se3 alloys requires a vessel capable of enduring extreme conditions. The quartz glass structure provides the necessary thermal resistance to withstand temperatures ranging from 900°C to 1150°C.

Simultaneously, the tube acts as a sealed chamber. It must maintain a high vacuum level of 10^-3 Pa throughout the heating process. This vacuum is essential to prevent oxidation or contamination from the ambient atmosphere.

The Graphite Barrier

The defining feature of these tubes is the graphitization of the inner wall. This carbon layer creates a physical shield between the metallic melt and the silicon dioxide of the quartz.

Without this barrier, molten metals at high temperatures have a high tendency to wet and adhere to quartz surfaces. The graphite effectively acts as a high-temperature release agent.

Why Graphitization Ensures Success

Preventing Chemical Contamination

At elevated temperatures, there is a risk of chemical interaction between the alloy components and the quartz glass. Such reactions would introduce impurities into the alloy, altering its properties.

The graphitized layer prevents this direct contact. By isolating the melt, it ensures the chemical purity of the Bi2Se3-Nd2Se3 alloy is maintained throughout the synthesis.

Facilitating Sample Removal

The success of the synthesis is not just about chemistry; it is about retrieval. If the alloy adheres to the tube walls during cooling, extracting the sample becomes difficult or destructive.

Graphitization ensures that the solidified ingot does not stick to the vessel. This allows for the successful removal of the sample without damaging the alloy or requiring the dangerous shattering of the quartz tube.

Critical Constraints and Trade-offs

Temperature Limitations

While the tubes are robust, they operate within a defined thermal window. The reference specifies a maximum operational temperature of 1150°C.

Exceeding this limit compromises the structural integrity of the quartz. It may also degrade the graphitized coating, leading to the very adhesion issues the tube is designed to prevent.

The Necessity of the Coating

The use of standard, non-graphitized quartz is a common pitfall in metallic alloy synthesis. Omitting the graphitization step almost invariably leads to sample adhesion.

This adhesion results in mechanical stress during cooling due to mismatched thermal expansion coefficients. This often causes the quartz tube to crack or the sample to fracture, ruining the experiment.

Making the Right Choice for Your Synthesis

To ensure the successful synthesis of Bi2Se3-Nd2Se3 alloys, apply the following guidelines:

- If your primary focus is alloy purity: Ensure the graphitization layer is uniform and intact to prevent any chemical leaching or reaction with the quartz substrate.

- If your primary focus is sample retrieval: Rely on the graphite coating as a release agent to ensure the ingot can be removed smoothly without mechanical extraction tools.

Graphitized quartz is not merely a container; it is an active component in ensuring the chemical and physical viability of your alloy synthesis.

Summary Table:

| Feature | Specification/Function |

|---|---|

| Primary Function | High-temp non-reactive vessel and release agent |

| Temperature Range | 900°C to 1150°C |

| Vacuum Integrity | Maintains up to 10^-3 Pa |

| Coating Material | Carbon/Graphite layer |

| Key Benefit | Prevents chemical contamination and sample sticking |

Elevate Your Material Synthesis with KINTEK

Precision in alloy synthesis starts with the right equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of material science. Our lab high-temp furnaces are fully customizable for your unique research needs, ensuring optimal thermal stability and purity for every sample.

Ready to optimize your synthesis process? Contact KINTEK today to find the perfect customizable furnace solution for your laboratory.

Visual Guide

References

- PHASE FORMATION IN THE TRINARY SYSTEM NdBi-Te ACCORDING TO THE SECTION Bi2Se3-Nd2Se3. DOI: 10.30546/209501.201.2024.1.04.035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What functions do graphite molds perform during the vacuum hot pressing of A356/SiCp? Optimize Your Material Density

- Why is a precision constant temperature drying oven required for BZT ceramic powders? Ensure Perfect Powder Quality

- What is the function of alumina crucibles in YBCO synthesis? Ensure Purity & Stability in Superconductor Production

- Why are alumina crucibles and mother-powder necessary for LLZO sintering? Ensure High Ionic Conductivity

- What role does a ceramic crucible play in oxidation weight gain experiments for Ti-V-Cr alloys? Ensure Data Accuracy

- What is the primary function of a high-energy planetary ball mill? Unlock Nanoscale Ceramic Pretreatment

- How do stainless steel furnace chambers and insulating linings contribute to thermal design? Boost Energy Efficiency

- What is the function of precision magnetic heating stirring equipment in BCZT ceramic preparation? Achieve Homogeneity