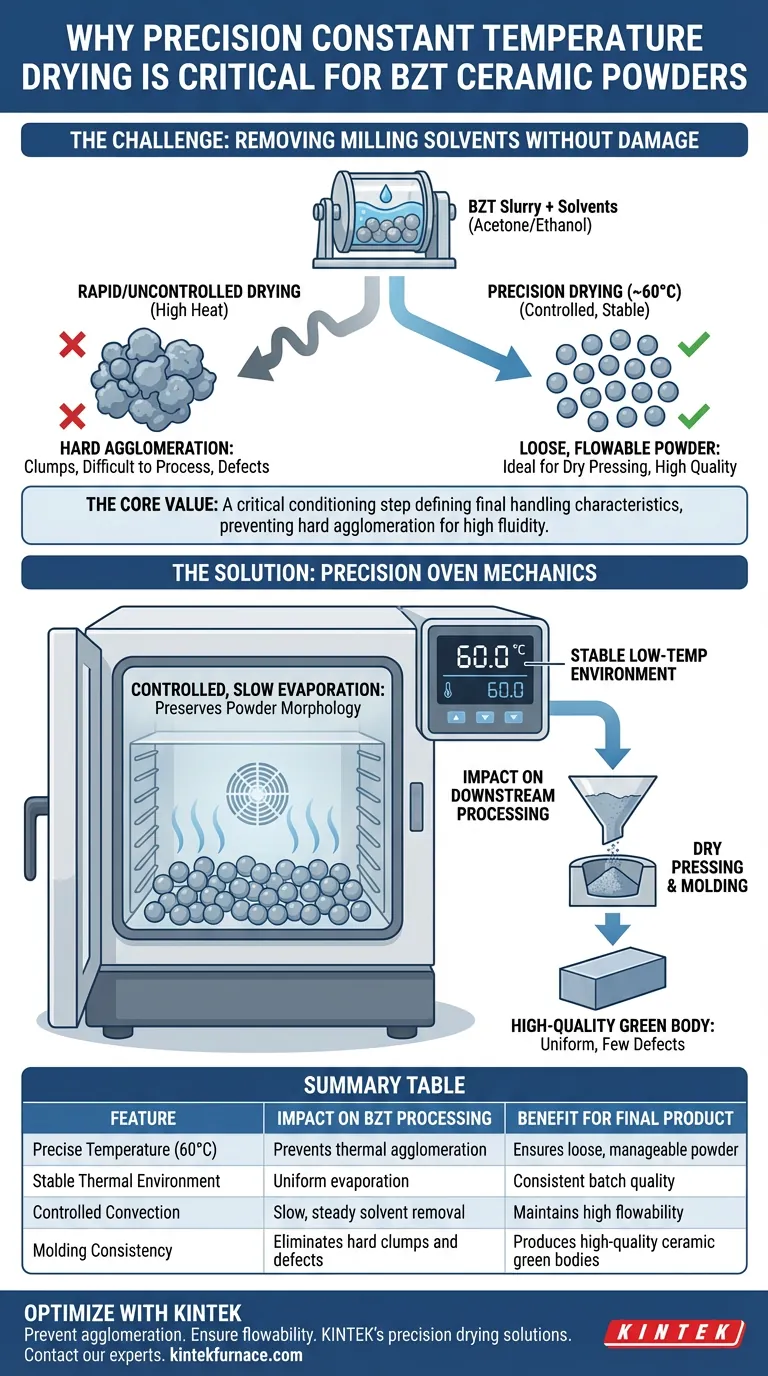

A precision constant temperature drying oven is essential for removing processing solvents without compromising the physical structure of the ceramic powder. Specifically for Barium Zirconium Titanate (BZT), this equipment maintains a stable, low-temperature environment (typically around 60 °C) to safely evaporate solvents like acetone introduced during milling. This controlled approach is the only way to ensure the material remains loose and suitable for subsequent manufacturing steps.

The Core Value The drying phase is not merely about evaporation; it is a critical conditioning step that defines the powder's final handling characteristics. By preventing rapid evaporation, the oven avoids "hard agglomeration," ensuring the BZT powder retains the high fluidity and loose consistency required for successful dry pressing.

The Mechanics of Controlled Solvent Removal

Managing the Milling Medium

Processing BZT powders involves a wet milling stage to achieve the correct particle size, often using solvents such as acetone or anhydrous ethanol.

Thermal Stability

Once milling is complete, this liquid must be removed. A precision oven provides a constant thermal environment. Unlike standard heating, which may fluctuate, a constant temperature ensures that the solvent evaporates at a steady, predictable rate throughout the entire batch.

Preventing Structural Degradation

Avoiding Thermal Agglomeration

The primary danger during drying is thermal agglomeration. If BZT slurry is dried too quickly or at uncontrolled high temperatures, the particles bind together tightly, forming hard clumps.

Preserving Powder Morphology

According to standard processing protocols, maintaining a temperature near 60 °C prevents these hard clumps from forming. This "soft" drying approach ensures the pre-treated powder remains loose and manageable, rather than fusing into a solid cake that is difficult to process further.

Impact on Downstream Processing

Ensuring Flowability

For the next stage of production—typically dry pressing and molding—the powder must flow like a fluid. Precision drying preserves this flowability.

Molding Consistency

If the powder suffers from agglomeration due to poor drying, it will not pack evenly into molds. By using a precision oven, you ensure the powder is uniform, which leads to a higher quality ceramic green body (the unfired object) with fewer internal defects.

Understanding the Trade-offs

Time vs. Throughput

The main trade-off in using a precision constant temperature oven at low temperatures (e.g., 60 °C) is time. This process is significantly slower than high-heat flash drying. However, prioritizing speed over precision invariably leads to hard agglomerates that require aggressive grinding later, potentially introducing impurities or altering particle size distribution.

Atmosphere Control

While a standard constant temperature oven is effective for basic solvent removal, it relies on air convection. For materials extremely sensitive to oxidation or requiring lower drying temperatures to protect active materials, a vacuum drying oven might be referenced as an alternative. However, for standard BZT processing focused on acetone removal, the precision constant temperature oven strikes the right balance between complexity and performance.

Making the Right Choice for Your Project

The specific requirements of your drying process depend on your production goals.

- If your primary focus is Powder Consistency: Prioritize a lower temperature setting (approx. 60 °C) and longer duration to maximize flowability and minimize clumping.

- If your primary focus is Oxidation Prevention: Consider upgrading to a vacuum environment if your specific BZT formulation is sensitive to air exposure during drying.

Ultimately, the precision oven serves as the quality gatekeeper between raw slurry and the finished ceramic form.

Summary Table:

| Feature | Impact on BZT Processing | Benefit for Final Product |

|---|---|---|

| Precise Temperature (60°C) | Prevents thermal agglomeration | Ensures loose, manageable powder morphology |

| Stable Thermal Environment | Uniform evaporation of acetone/ethanol | Consistent batch quality and particle size |

| Controlled Convection | Slow, steady solvent removal | Maintains high flowability for dry pressing |

| Molding Consistency | Eliminates hard clumps and defects | Produces high-quality ceramic green bodies |

Optimize Your Ceramic Powder Processing with KINTEK

Don't let poor drying compromise your material integrity. KINTEK’s precision drying solutions prevent hard agglomeration and ensure the high flowability required for superior BZT ceramic production.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique research or production needs.

Take control of your material quality today. Contact our experts for a custom solution.

Visual Guide

References

- T. Avanish Babu, W. Madhuri. Energy storage and catalytic behaviour of cmWave assisted BZT and flexible electrospun BZT fibers for energy harvesting applications. DOI: 10.1038/s41598-024-52705-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why are alumina liners and quartz boats selected as consumables for sintering lunar soil simulant? Key Material Roles

- What is the function of graphite molds in the Spark Plasma Sintering (SPS) of high-entropy alloys?

- Why is it necessary to achieve a vacuum level of 3 x 10^-2 mm Hg for quartz tube sealing? Ensure Safety and Purity

- How does a high-precision heating stage contribute to the drying and crystallization of FAPbBr3 nanosheets?

- What is the purpose of a laboratory vacuum system in photocatalytic hydrogen evolution? Ensure Accurate Data Results

- What is the purpose of using a high-purity ceramic crucible with a sealed lid during the thermal treatment of biochar?

- What is the function of a copper turning purification device? Enhance Your Sintering Furnace Gas Purity

- What are the reasons for using high-purity alumina material for the reaction tubes in a Drop Tube Furnace? - Guide